ATSG Series Fluid Bed Processor

We are engaged in the Manufacturing, Exporting and Supplying of ATSG Series Fluid Bed Processor. We use high grade components for the manufacturing of ATSG Series Fluid Bed Processor. The ATSG Series Fluid Bed Processor is tested on different parameters by our experts to assure its flawless quality. Our ATSG Series Fluid Bed Processor is used for diverse applications in Pharmaceutical manufacturing.

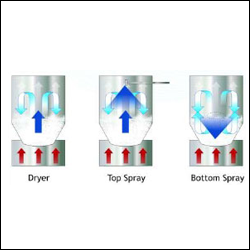

Basic Concepts

Granulation

Dry mass is charged into mobile product container. This product container is fitted onto the machine by means of pneumatic pressing device. Fluidization is created by the system's induced draft blower. The filtered air passed over by steam air heater is induced into the product container which in tum creates a fluidization effect for the mass

Binder is sprayed from top side (counter current spraying) through the spraying system

This continuous fluidization with the help of controlled. filtered hot air removes the moisture from the mass and thus the mass is granulated

Dry mass is charged into mobile product container. This product container is fitted onto the machine by means of pneumatic pressing device. Fluidization is created by the system's induced draft blower. The filtered air passed over by steam air heater is induced into the product container which in tum creates a fluidization effect for the mass

Binder is sprayed from top side (counter current spraying) through the spraying system

This continuous fluidization with the help of controlled. filtered hot air removes the moisture from the mass and thus the mass is granulated

Pelletfzation

Dry particles or pellets are charged into mobile product container. This product container is fitted onto the machine by means of pneumatic pressing device

Fluidization is created by the system's induced draft blower. The filtered air passed over by steam air heater is induced into the product container which in turn creates a fluidization effect for the mass

Spraying solution is sprayed from bottom side (co current spraying) through the spraying system

This continuous fluidization with the help of controlled, filtered hot air removes the moisture from the mass and thus the particles or pellets are coated

Applications Areas

Pharmaceutical Industry

Chemical / Bulk drug Industry

Food Industry

Feedstuff industry

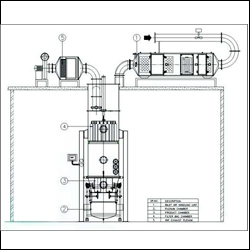

Basic Components

Inlet Alr Handler sections

The standard inlet Air Handling unit is a Horizontal Plenum Chamber with ·

Pre Filter

Steam / Electrical Air Heater

Fine Filter

Options

HEPA Filters

Dehumidifier/Humidifer

Face and Bypass System

Insulated Panel Chamber

Product Processing sections

This is the most important section of the system which can be either

Product Container with top spray option for drying and granulation

Product Container with bottom spray option for particle coating and pelletization

Integrated Expansion and Filter Bag Chamber

Single filter bag section for granulation option

Twin filter bag section for pelletization

Filter bags with larger surface area & automated bag shaking arrangement

Anti - static filter bags, SS candle filters as an options

Product charging and discharging ports

WIP system

Single arm - Single head / Multi head top spray nozzel

Single/ Mutiple HIGH SPEED Bottom spray nozzel

Exhaust Air Handler Sections

The standard Exhaust Air Handling unit consists of special dynamically balanced high efficiency induced draft blower

Options

Police filter plenum with HEPA Filters

Solid flow monitor for particle escape prevention

Water base scrubbing system

Silencer

Spark proof impeller for blower

Machine Control System

Options

Specifications

| Model - ATSG Combo | 5 | 25 | 25 | 125 | 250 | 500 | 800 | 1300 |

| Container Volume in Litres Bottom spray | Na | 20 | 40 | 110 | 200 | 400 | 600 | 1000 |

| Container Volume in Litres Top spray | 5 | 25 | 50 | 125 | 250 | 500 | 800 | 1300 |