Roto Granulator

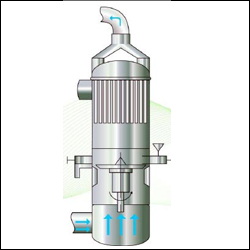

We are engaged in providing Roto Granulator to the customers. Roto Granulator also known as Tangential Spray processor or Rotary Disk Processor belongs to the family of Fluid Bed Processors & works on the principle of Air Suspension Particle Processing. The main advantage of Roto Granulator over the other coating machines is that the drug can be loaded on pellets in powder form, eliminating the need of forming drug suspension. The process is called Solid Drug Layering. Powder is deposited on the rotating bed of pellets at controlled delivery rates & the binder solution is simultaneously sprayed tangentially in order to form the uniform layers of the drug onto the pellets. In last few years, Roto Granulator has emerged as a beneficial machine for particle processing than conventional machines.

We are engaged in providing Roto Granulator to the customers. Roto Granulator also known as Tangential Spray processor or Rotary Disk Processor belongs to the family of Fluid Bed Processors & works on the principle of Air Suspension Particle Processing. The main advantage of Roto Granulator over the other coating machines is that the drug can be loaded on pellets in powder form, eliminating the need of forming drug suspension. The process is called Solid Drug Layering. Powder is deposited on the rotating bed of pellets at controlled delivery rates & the binder solution is simultaneously sprayed tangentially in order to form the uniform layers of the drug onto the pellets. In last few years, Roto Granulator has emerged as a beneficial machine for particle processing than conventional machines.

Our company is amongst the leading Manufacturers and Suppliers of Roto Granulator. The features like carefully designed & accurately machined rotary disk, impart the desired centrifugal motion to the product bed.

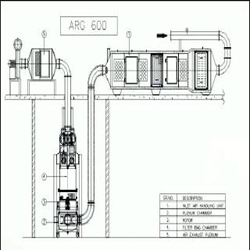

Anish Roto Granulator is also available in combo model with the attachment of Top spray or Bottom spray or both attachments to perform as a full-fledged Fluid Bed Processor. We also supply R&D Table Top models in order to develop the product at very small batch size. With all its latest features & with the efficient service back up, Anish Rotoprocessors have emerged as a high performance particle coating machine.

Anish Rotogranulator is supported with sophisticated instrumentation & automation with user friendly Human Machine Interface (HMI). The Programmable Logic Controller (PLC) enables setting, controlling & data acquisition of all the process parameters.

Working

The fine Non Peril Seeds are subjected to rotary motion on a disk rotating at desired speed. The gravitational force on particles along with the force of air & the centrifugal force together form a spinning rotary bed. Binder solution is sprayed tangentially to facilitate various processes viz. Solid Drug Layering, Seal Coating, Enteric Coating, Test Masking, Moisture barrier coating etc.

Available With

A full set of validation documents such as Design Qualifications ( DQ), Installation Qualifications (IQ), Operational Qualifications is (OQ) is available on request.

Attributes

Machine complying the CGMP standards

2 bar pressure shock resistant construction

Twin chamber design for un-interrupted process

Provision of on line spray gun cleaning

On line Sampling port

Safety interlocks for operational ease

Heating media : Steam/ hot water/ electricity

Provision of Dehumidifier / Humidifier on request

Provision of automatid solid drug delivery system on request

Flame proof components for hazardous zones

Available in Combo Models

Validation Documents available on request

Benefits

Uniform coating

Improvement in the flowability

Negligible agglomeration

Controllable bulk density

Kinds of coatings

Solid Drug Layering

Solid Drug Layering

Seal Coating

Taste masking

Moisture and oxidation-protection coatings

Enteric coatings

Applications

Pharmaceuticals

Bulk drugs

Nuetraceuticals

Chemicals

Foods