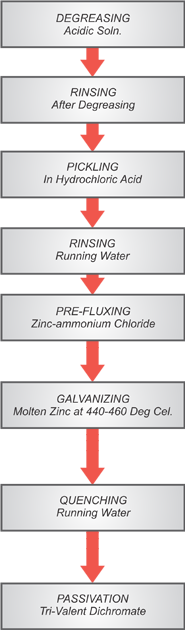

HOT - DIP GALVANIZING - PROCESS

STEP -1

STEP -1

For grease & oil removal from the surface of steel, It is immersed in acid base degreaser.

STEP-2

To clean the surface of carry over salts for effective acid cleaning.

STEP-3

The rust scale & mill scale are removed from the surface of the steel by passing it through 15 to 20% conc. HCL.

STEP-4

Steel is again rinsed to remove acid & iron salts.

STEP-5

Steel is then passed through hot zinc,ammonium chloride to prevent oxidation & ensure that the surface is prime before molten zinc immersion.

STEP-6

Oxide free steel is immersed in molten zinc at a temperature of 450-460 deg Celsius to form zinc–iron alloy. The period of dip depends on the zinc & weight of steel item immersed.

STEP-7

The steel immersed in molten zinc is slowly withdrawn & immersed in cold water to ensure a metallurgically strong bond to steel completely covering the whole steel.

STEP-8

The steel is immersed in Di-chromate solution for providing an envelope film for additional protection to zinc coating during transit or wet storage stains in warehouse.