Blackfast Chemical

Blackfast is used throughout the metal working industry.

Blackfast is used throughout the metal working industry.

The following is a list of some universally known customers and the equipment that they manufacture:

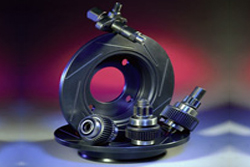

Hand tools : Sandvik, Bahco, Euro Tools, Footprint Tools, Stanley Tools, Sykes Pikavient, Draper Tools, L.S.Starrett e.g. wrenches, pliers, sockets, spanners, guages, wood working tools, taps, dies, drills.

Metal working equipment : Cincinnati Milacron, J.S.Henderson, Colchester Lathe, Yamazaki Mazak, Aida Bliss, Addison McKee e.g. lathes, cutting, stamping, bending, lapping, grinding, bench top equipment, punches, presses.

Tool holders and cutters : Sandvik, Kennametal Hertel, Bristol Tool and Guage.

Machine builders : Machines for printing, drinking cans, cigarettes, textiles, shoes, food processing, packaging, pipe bending, gas turbines, slide systems, conveyors.

Workholding : workholding equipment specialists and tool rooms.

Automotive : specialist equipment companies, tools and racing / sports sector.

General industrial equipment : clutches, transmissions, drives, hydraulic blocks, and fasteners.

Metal working contractors : the largest single market group.

Gun and model hobbyists : Blackfast is sold as small blacking kits directly to the public. This is usually undertaken by a distributor who specialises in this industry sector.

Metal finishing contractors : Mechanical industry applications.

User Benefits:

-

1) No dimensional change:

Many machined parts are manufactured to a tight tolerance, which means plating or painting are not acceptable.

-

2) Corrosion resistance:

-

The black surface absorbs wax, oil or rust preventative sealants to give corrosion protection.

-

3) Sales appeal:

-

A durable black finish enhances the appearance and value of a wide range of manufactured articles.

-

4) Safety By reducing light glare from moving tooling or machinery, it eases fatigue and contributes to operator safety.

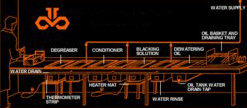

A simple and cost effective process for chemically blackening iron and steel at room temperature is now available requiring no chemical knowledge and producing no environmental hazard. Blackfast chemicals process is suitable for engineering works, workshops and tool rooms. By straightforward immersion in a series of tanks precision-engineered components are rendered a deep black with no change to their overall dimensions. The benefits are lower cost, fast turn around in finished product, reduction in component stocks, flexibility and in-house quality control.

A simple and cost effective process for chemically blackening iron and steel at room temperature is now available requiring no chemical knowledge and producing no environmental hazard. Blackfast chemicals process is suitable for engineering works, workshops and tool rooms. By straightforward immersion in a series of tanks precision-engineered components are rendered a deep black with no change to their overall dimensions. The benefits are lower cost, fast turn around in finished product, reduction in component stocks, flexibility and in-house quality control. Blackfast is used throughout the metal working industry.

Blackfast is used throughout the metal working industry. Blackfast is used throughout the metal working industry. The following is a list of some universally known customers and the equipment that they manufacture: hand tools sandvik, bahco, euro tools, footprint tools, stanley tools, sykes pikavient, draper tools, l. S. Starrett e. G. Wrenches, pliers, sockets, spanners, guages, wood working tools, taps, dies, drills. |

Blackfast is used throughout the metal working industry. The following is a list of some universally known customers and the equipment that they manufacture: hand tools sandvik, bahco, euro tools, footprint tools, stanley tools, sykes pikavient, draper tools, l. S. Starrett e. G. Wrenches, pliers, sockets, spanners, guages, wood working tools, taps, dies, drills. | Room temperature blacking line (20 liters) Locate a permanent site close to the machining center Access to running water and drainage. Install tanks at a comfortable working height.

Room temperature blacking line (20 liters) Locate a permanent site close to the machining center Access to running water and drainage. Install tanks at a comfortable working height. Room temperature blacking line (20 liters) Locate a permanent site close to the machining center Access to running water and drainage. Install tanks at a comfortable working height.

Room temperature blacking line (20 liters) Locate a permanent site close to the machining center Access to running water and drainage. Install tanks at a comfortable working height.