¦ Length & Angle Standards -> Gauge Blocks

The years of experience & our consistent innovative approach has helped us develop world class Gauge blocks. KCP has developed special production techniques to enhance the required characteristics of the materials.

Ψ Unique Features

Ψ Material Advantages

Ψ Calibration Certificate

• Highly accurate, very low deviation from flatness,

surface finish & nominal length.

• High resistance to wear & dimensionally stable

• Superior wringing quality

• Each gauge block is marked for size & serial

number

Ceramic - Ceramic gauge blocks are extremely resistant to wear and scratches. As a result, any minor damage to the wringability of their measuring face is unlikely. Corrosion resistant, these gage blocks are resistant to sweaty hands, and normal wear and tear.

Carbide - They are highly resistant to wear and thus ideal where the gauge blocks are used heavily. The study confirms that the Tungsten Carbide gauge blocks are of 10 times greater wear resistant than that of steel and thus extremely economical.

Steel - Steel gauge blocks are widely used since most of the manufacturing components are made from steel which nullifies the measurement difference due to same thermal coefficient of expansion. Steel is ideal for regular use when used with proper care & regular maintenance.

KCP Gage Blocks are supplied with Calibration Certificate issued from its accredited calibration lab.

KCP Gage Blocks are supplied with Calibration Certificate issued from its accredited calibration lab.

All our Length standard products and accessories are delivered in quality wooden casing, appended with; Calibration Certificate traceable to National Standards and Instruction Manual on the use and care

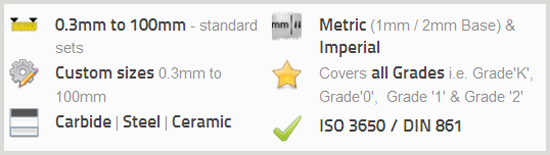

Ψ Specifications

Ψ Know your Gauge Blocks

• Standard Gauge Block Sets (Metric) as per ISO 3650 - 1mm base gauge block.

• Standard Gauge Block Sets (Imperial)as per BS 4311

• Limit Deviations and Tolerances.

• Standard Dimension of Gauge Blocks upto 100mm.

• Selection of Material.

• Selection of Grades

• Maintenance of Gauge Blocks