Description

NTB ALU-EX HI-TEMP FELTS Manufactured exclusively from DUPONT Kevlar & Nomex fibres imported from globally acknowledged manufacturer of TRULYENDLESS FELT BELTS for ALUMINIUM EXTRUSION INDUSTRIAL APPLICATIONS. They are widely used throughout the aluminum extruding process, as a substitute for wood strip and plumbago. These materials possess a unique combination of characteristics including excellent resistance to prolonged high temperature exposure, excellent abrasion resistance and a smooth surface which does not scratch aluminum profiles. NTB ALU-EX Belts are Truly Endless, Heat Resistant, Needled Felts that have been developed for usein extremely HIGH TEMPERATURE applications. The belts can even be configured with welding of Tracking Profiles, Timing Belts & Chains to possess high friction properties positively & to avoid any chance of differential speeds. Hence it fits to your requirements & makes it perfectly suitable forequipment in your kind of application.

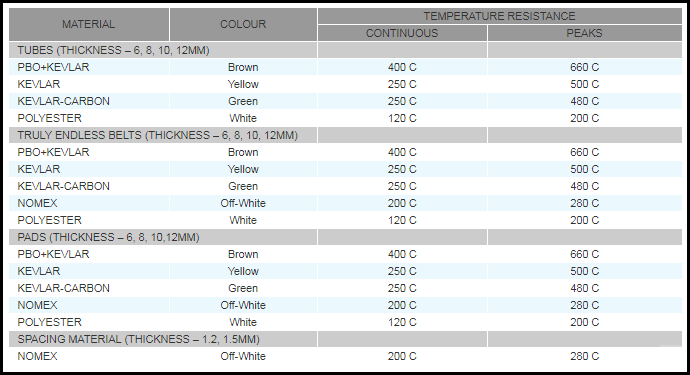

Zylon-PBO : Temperature Resistance: Continuous: 400°C, Max: 600°C

Zylon-PBO : Temperature Resistance: Continuous: 400°C, Max: 600°C Kevlar-K (Strength: 25N/mm at 1% Elongation), Nomex-N (Strength: 10N/mm at 1% Elongation),Polyester-P (Strength: 15N/mm at 1% Elongation)

Kevlar-K (Strength: 25N/mm at 1% Elongation), Nomex-N (Strength: 10N/mm at 1% Elongation),Polyester-P (Strength: 15N/mm at 1% Elongation)