A boiler chimney is a structure manufactured for venting hot flue gases from a boiler to the outside atmosphere.

We design and manufacture chimneys according to the specific needs of customers. Chimneys are designed taking into consideration the height of the chimney, the diameter and the wind velocity. Correct design of the chimney ensures that the flue gases are efficiently transported into the atmosphere without and back pressure on the boiler.

Our chimneys are designed & manufactured for long life and easy installation.

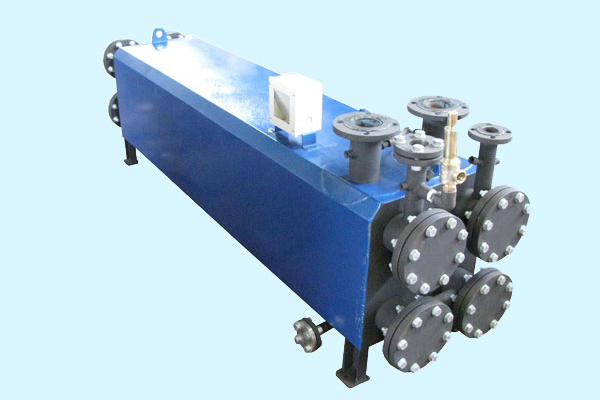

These are conventional shell and tube heat exchangers, custom built as per specific inquiries. In industrial and commercial applications where direct steam or hot water from boilers cannot be used, these calorifiers provide efficient and safe heat exchange to supply hot wafer at required temperature and pressure. We also fabricate calorifiers as per designs supplied by customers.

These ore preparatory units for combustion of heavy fuel oil in fired heaters and boilers. One of the pre-requisites of efficient combustion of heavy oil is fine atomization, for which heavy oil needs to be heated and pumped at specified temperature and pressure. This is achieved through the use of fuel oil ring mains and OPH stations designed & built for various firing capacities. Fuel pumps are internal gear type positive displacement pumps & pre-heaters are mostly electric.

Custom built economizers, steam generators, hot water generators, thermic fluid heaters and air preheaters can be offered to work on exhaust flame bases generated by diesel engines, furnaces, boilers and other fired units to meet customers specific requirement. Innovative energy efficient units like thermosyphon, flash steam generator, evaporator and super-heater can be designed to replace existing traditional systems.