About GRANULATION LINE

Ball Mill

Ball Mill

Description

Ball Mill is one type of milling machine which is used to mill or grind the materials such as large sized particles either active drug ingredients or excipient and agglomerates.

Ball mill consists of horizontal rotating cylindrical vessel or shell with the length slightly greater than its diameter which is mounted on a metallic frame in such a way that it can be rotated on its longitudinal axis. The axis of the shell or vessel may be either horizontal or at a small angle to the horizontal. The cylindrical vessel contains balls that occupy 30-50% of the mill volume.

The grinding media is the balls which may be made up of stainless steel. The ball size depends upon the feed and the dia of the mill.

Rotary Mill

Description

It comprises a milling head, Conical Sieve and an impeller. The high speed rotary action of the impeller causes the material to get pushed through the holes of the sieve. The precise apertures of the sieve prevent any material from paring until the product has been milled to the required particle size.

Advantages

- High output as much as 30% higher as compared to conventional mills.

- Due to compact and simple design, the light weight milling head can be removed from the shaft quickly and easily.

Hygienic fast and simple cleaning and minimal maintenance provide optimum operational availability to minimize operating cost.

Universal Mill

Description

Flexible option of Hammer milling as well as impeller milling with the changeover of head possible.

Salient Features

- Easy to clean

- Minimum maintenance.

- Bin Charging system for loading and unloading of powders and granules for complete dust free operation.

- Excellent for contained milling.

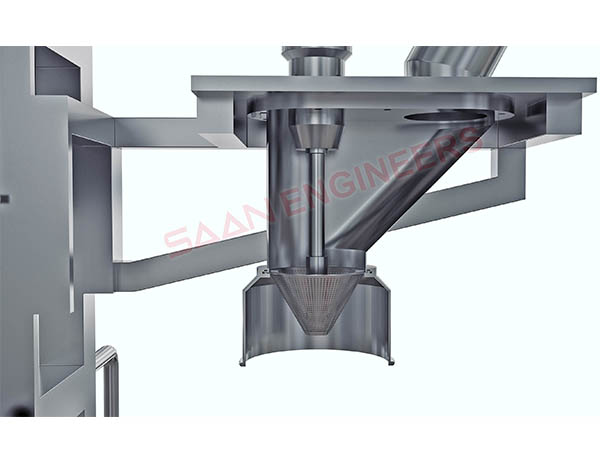

Cone Mill

Description

Its low speed design applies an inherently gentle action to the product, achieving optimum particle granulometry while generating limited heat, low noise and minimal fines. Is extensively used for even heat sensitive materials.

Salient Features

- In feed chute can be customized to meet all process feed requirements

- Swing away discharge should allow quick changeover of screens impellers, customized tooling for special applications. Also allows for easy cleaning.

- Machine housing with super sanitary spindle assembly can also be modified for cleaning place operation..

Multi Mill

Working Principle

Multi-mill is designed to utilize the principle of variable forces swing beaters having both knife and impact edges rotating within a selected screen to control the particle reduction. Material fed in to the processing chamber moves to the periphery and passes through the screen radically and tangentially. Finally the processed material gets collected into the container kept below the processing chamber.

Salient Features

- Multi speed drive for various product milling

- Easy dismantling and cleaning

- High degree of surface finish

- Easy portability

- AC frequency drive option available

Sifter Cum Mill

Description

A perfect combination of sifting and milling, the equipment was conceived to prevent handling of powder between separate sifting and milling operations. The separation of coarse and fine product size happens in the sifting chamber. The fine powder falls into the main discharge port, while the coarse particles proceed to the adjacent milling chamber. These particles are further broken into fines, which flows to the mail discharge port, thus attaining the uniform product size. The SS 316 sieves present in the sifting and milling chamber actually determines the final product size.

Quite extensively used in applications of continuous batch size.

Salient Features

- Air purging interlocks provided at the shaft entry of the sifting and milling chambers.

- Pneumatic limit switches provided to ensure proper closing of the lids.

- Inflatable gaskets provided at the interface of the respective chambers to ensure no leakage of the powder particles into the surroundings.

- AC frequency drives provided for regulating the sifting and milling speed respectively based upon the validation procedures.