Processing Plant & Machinery

We have proven our metal by fabricating state of the art Fruit & Dairy processing plant & machinery sauce and puree processing unit. Our cost effective range of fruit & dairy processing plant and machinery is known for offering accurate dairy product, tomato paste, tomato puree, tomato sauce & tomato ketchup processing results. Clients can purchase this premium & durable range at very economical rates from us.

Tomato Ketchup Processing Plant & Machinery

Tomato Ketchup / Paste / Sauce Processing Plant & Machinery

We manufacture and install tomato processing plant & machinery for tomato Paste, Ketchup, Sauce.

We supplied tomato processing equipments such as Tomato washer, conveyor, crushing, pasteurization, evaporation, filling & packaging bottles & pouches.

Tomato paste processing line in cold-break and hot-break system starting from 2 to 20 ton/hour with different level of automation and different feeding systems of whole tomato.

Can be used to make as tomato puree tomato paste, tomato ketchup, tomato sauce and peeled tomato in cans.

The packaging product in cans, bottles, pouches, aseptic bag in drum

Tomato Ketchup / Paste / Sauce Processing Plant & Machinery

We manufacture and install tomato processing plant & machinery for tomato Paste, Ketchup, Sauce.

We supplied tomato processing equipments such as Tomato washer, conveyor, crushing, pasteurization, evaporation, filling & packaging bottles & pouches.

Tomato paste processing line in cold-break and hot-break system starting from 2 to 20 ton/hour with different level of automation and different feeding systems of whole tomato.

Can be used to make as tomato puree tomato paste, tomato ketchup, tomato sauce and peeled tomato in cans.

The packaging product in cans, bottles, pouches, aseptic bag in drum

Capacity of the plant :- 0.5/1/2/5/10/15/20 Ton per hour.

Our lines are characterised from long-experience know-how, strong construction and energy saving.

Complete sets of tomato ketchup & paste & puree production line:

1. Washing Machine

2. Sorting Conveyor

3. Elevator

4. Crusher

5. Cold/Hot Break System

|

6. Tubular Preheater Pasteurizer

7. Pulping Machine

8. Vacuum Evaporator / Continuous / forced circulation evaporator

9. Filling Line-- Can Filling Machine / Bottle Filling Machine / Sachet filling Machine / Aseptic bag in drum filling machine

|

Mango Processing Plant & Machinery

We are manufacturing & supplying complete mango processing machinery on turnkey basis for the production of mango pulp, juice & concentrated puree, as well as single machines to meet specific requirements.

We are manufacturing & supplying complete mango processing machinery on turnkey basis for the production of mango pulp, juice & concentrated puree, as well as single machines to meet specific requirements.

Mango processing equipments are used for Washing, Sorting, Destoning, Pasteurization, Filling & Packaging.

Can be used to make as Mango Pulp, Mango Slice, Mango Concentrate, Mango Juice and puree, Mango chutney

Capacity of the Plant :- 0.5/1/2/5/10/15 M Ton per hour.

Complete sets of Mango Pulp & Juice Production Line:-

1. Washing Machine

2. Sorting Conveyor

3. Elevator

4. Pulping Machine / turbo refiners

5. Tubular Preheater Pasteurizer

6. Filling & Packaging Line - Can Filling Machine / Bottle Filling Machine / Aseptic bag Filling Machine / Gable top packaging / Easy to open can

Milk Processing Plant & Machinery

Shiva Engineers supplies integral processing and packaging solutions for the dairy industry, from milk reception and transformation processes to filling and packaging solutions.

Shiva Engineers supplies integral processing and packaging solutions for the dairy industry, from milk reception and transformation processes to filling and packaging solutions.

Shiva Engineers covers the entire process and manages each stage, including product design, process definition, line layout, machinery selection, installation, and commissioning and production accompaniment during the start-up period.

Shiva Engineers has the know-how and technical expertise for the design, integration and manufacture of production plants to transform fresh milk into a wide variety of dairy products:

• Pasteurized, sterilized and UHT milk, with different fat content

• Cream: raw, pasteurized and prepared creams

• Butter

• Cultured milk products: yogurt, kefir, others

• Others such as casein, whey

We are manufacturer of milk cooling tanks and milk processing machines, all necessities for a full technology cycle. Shiva Engineers is an Engineering Company involved in design and manufacturing of milk cooling tanks and milk processing machines, all necessities for a full technology cycle including reception and cooling of milk, pasteurization, separation, fermentation, packing of ready products.

Our Processing technologies include:

• Fresh milk reception units & Tank farm equipment

• Aseptic technologies, UHT plants, Pasteurization and sterilization technologies

• Product recovery systems

• Product deaeration technology

• Separators

• Homogenization units

• Mixing, weighing, dosification and control technology

|

• Powder dissolution units

• Tanks and storage tanks

• Evaporators (falling film, forced recirculation, other.)

• Filtration systems

• Filling and packaging lines

• CIP & SIP systems

|

All our machinery are manufactured on customer requirement basis, for all popular kinds of dairy products such as fresh pasteurized milk, yogurt, sweet and sour cream, soft, hard and semi hard cheeses, white cheese in brine (feta), butter, ice-cream.

Juice Processing Machinery

Beverages Lines from concentrate to Juice Packaging

Beverages Lines from concentrate to Juice Packaging

Fruit Juices are made from fruit pulp/concentrate. Artificial sugar may or may not be added to the juice extracted.

The sugar syrup is prepared first in jacketed mixing tank and then it is mixed with fruit pulp, water along with other ingredients like flavor, color, preservatives etc. in the other mixing tank.

This mixture is pasteurized to remove any microbial growth from it and later on homogenized to prepare a uniform blend of juice.

Sun Engineers also helps the agro food industry in the transformation of their agricultural products into other products other than juices. Please see our agro-food section.

The process of making juice varies from factory to factory. Juice can be made out of fresh fruit, vegetables, concentrate, frozen fruit paste or aseptic mix. If produced from fresh fruit, all the equipment for fruit and vegetable storage, selection, cleaning and extraction need to be corresponding. This means that a different processing line for fresh fruit and vegetable extracting is required.

If made out of concentrate or aseptic mix paste the ingredients go straight to the mixing and blending units where they are mixed in either a batch or a continuous system. Nowadays manufacturers tend to produce numerous different juice varieties resulting from an assortment of concentrates or fruits. The same production line can be used to produce different types of juices. CIP systems can guarantee complete hygiene throughout the entire process whilst using the same production line for different products.

When it comes to orange juice, another process is involved as the enzymes have to de deactivated before the liquid can be pasteurized. In certain processes a homogenizer might also be required to guarantee the homogenized mixture of the ingredients.

Most juices are packed in aseptic packaging. Those that are intended to be kept and stored in the fridge are packed using ultra clean packing technology, and those that come in glass bottles are usually hot filled.

By products or waste products that result from the production of juices - such as pulp - can also be reproduced to create dehydrated feed for livestock, pectin for use in making jellies, citric acid, essential oils, molasses, and candied peel. Certain fractions of orange oil (known as d-limonene), have excellent solvent properties and are sold for use in industrial cleaners.

Complete sets of Fruit Juice / Beverages and soft drinks Production Line:

1. Sugar Syrup Preparation Tank

2. Fruit Pulp Storage Tank

3. Filter Press

4. Blending

|

5. Homogenization

6. Standardization

7. Pasteurization

8. Filling Line: - Automatic Bottle Filling Line with Rinsing Filling & Cap Sealing Machine

|

In addition to the above machine, we can also offer a bottle blow molding plant which will make bottles for you from PET Preform per your desired shape and size.

Capacity: - Min 500 Kg /Hr Max 10 Ton/Hr

Fresh Fruit & Vegetable Cleaning, Sorting, Grading & Packing

We specialize in the designing and manufacturing of vegetable processing machinery.

We specialize in the designing and manufacturing of vegetable processing machinery.

Complete lines and technology for vegetable processing as well as reliable service worldwide by our skilled engineering.

It is our goal to be of service to our customers as effectively as possible.

Vegetables processing line fully absorbs advantages of advanced equipment from abroad with many new technology and technique being the widely and advanced auto production line before quick-freezing in domestic market. and it is proved by hundreds of quick-freezing factories by practice from home and abroad the the line is scientific in design, reasonable in layout, reliable in running and convenient in operation, wide use in vegetable processing, effective in treatment, investment and energy saving, being the most ideal, advanced and economical production line

This machinery is for processing of fruit like Mango, Tomato, Guava, Orange & Banana Cleaning Sorting Grading & Packing.

Complete Sets of Vegetable Processing Production Line.

1. Slicing

2. Washing

3. Sorting

4. Blanching

5. Cooling

|

6. Dewatering

7. Quick Freezing

8. Packaging

9. Storting

|

Jam, Squash, Jellies, Marmalade Processing Machinery

We supply batch or continuous type jam/marmalade making machinery.

We supply batch or continuous type jam/marmalade making machinery.

Making fruit pastes with a high percentage of sugar concentration is a traditional way of naturally preserving and storing fruit. A high concentration of sugar slows the generation of microorganisms, and the boiling process pasteurizes the fruit - extending its shelf life.

Jam, Squash, Jellies, Marmalade and Fruit Paste factories require complex operations. Strict quality control and regulations are enforced and need to be adhered to for the product to be distributed to the mass market.

Fruit pulps and other fruit side products resulting from the production of juices can be used for Jam, Squash, Jellies, Marmalade making.

Manufacturers of Jam, Squash, Jellies and Marmalade usually buy fruit concentrates in industrial packages. There are some but few that produce them straight from fresh fruit processing.

As a general rule the process consists of boiling fresh and/or pre-cooked fruits or pulp with a high concentration of sugar and pectin. Citric acid can also be added to further preserve the product and extend its shelf life. A high percentage of water has to be evaporated to form the highly concentrated paste, and ingredients have to be mixed rigorously in the mixing units before being pasteurized and then filled and packed. Hot filling is the technology that is most commonly used for packaging purposes.

Sun engineers installs complete plants and process for the production of Jam, Squash, Jellies and Marmalade. Although each plant is individually designed to meet customers’ needs and product requirements, as a general rule the typical manufacturing plant for Jam, Squash, Jellies and Marmalade contains the following equipment:

Filling is done in glass bottles/pet bottles

We are manufacturing machinery plant for Jam, Squash, Jellies and Marmalade contains the following equipment:

1. Kettle

2. Conveyor

3. Press

4. Storage System

|

5. Mixing Units - Blending Units

6. Vacuum Pan

7. Filling & Packing Ling

|

Capacity: - Min 500 Kg /Hr Max 10 Ton/Hr

We can also install a complete production process for you, from start to finish

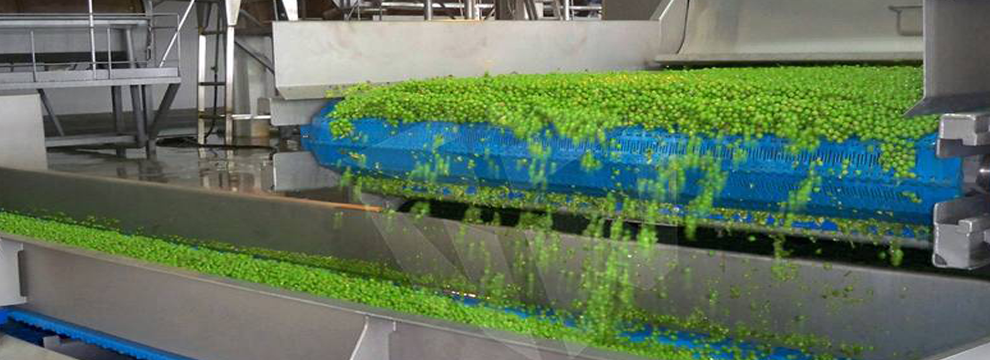

Pea Processing Machinery

Green Pea Processing Equipment

Green Pea Processing Equipment

We can provide complete vegetable / pea lines for the processing of green peas, vegetables-IQF for capacities between 1 and 5 tons/hr. Our experience includes solutions for all steps of the processing of podded raw material:

Suitable for separation of grains from the pods.

Machine, rotor beater blades etc: are made out of S.S 304.

Conveyor is fitted with S.S rollers, flanged bearing on one side and take-up bearing on the other side for tensioning.

The apron conveyor belt is made out of food grade PVC quality.

The conveyor belt is endless.

The liners, guards covers, hoppers, etc. are made out of S.S.304

Reliability of vegetable processing machines, hygiene, precision and a long life.

Complete sets of pea processing production line.

1. Removal of light foreign matters, such as pods, leaves, etc.

2. Washing to remove sand, stones, stems, etc.

3. Blanching to maintain taste, colour and nutrients

4. Cooling

|

5. Freezing

6. Grading in different size

7. Weighing, Filling & Packaging into Bag, Can

|

Ginger Processing Machinery

We specialize in the designing and manufacturing of Ginger processing machinery.

We specialize in the designing and manufacturing of Ginger processing machinery.

Complete lines and technology for Ginger processing as well as reliable service worldwide by our skilled engineering.

It is our goal to be of service to our customers as effectively as possible.

Raw gingers are separated from roots and leaves.

The ginger is cleaned and separated from bad ginger.

Cleaned gingers are peeled and chopped and send to a soaking unit for a definite period.

Soaked gingers are dried in a specially designed dryer.

Essential oils and oleoresin extracted from the ginger.

The dried gingers are then pulverized to make it powder and further are packed as per requirements.

Complete Sets of Ginger Processing Production Line.

1. Washing

2. Sorting

3. Blanching

4. Cooling |

5. Slicing

6. Crushing

7. Preheater / Pasteuriser

8. Filling & Packaging |

Vegetable Processing & Freezing Machinery

Vegetable Processing & Freezing Machinery

Vegetable Processing Machinery/ Fresh cutting dicing & freezing lines to make salad/Slicer/Cube Making Machinery.

Vegetable Processing & Freezing Machinery

Vegetable Processing Machinery/ Fresh cutting dicing & freezing lines to make salad/Slicer/Cube Making Machinery.

It includes sorting, cleaning, blanching, cooling, freezing, packing & storage.

We use most modern technology equipments in vegetable processing machinery.

Leafy vegetables processing

Leafy vegetables can be sorted on sorting conveyor/ tables. Cleaning is done in vegetable washer; blanching & cooling is done in belt type conveyor/chamber

Extra water removed on shaker/dewatering machine.

Vegetable inspection & metal detection on conveyor if quantity is more/large; optical sorter

Can be used.

• Freezing by blast freezer/ IQF

• Packed into bags & stored in cold rooms.

• Transfer into refrigerated van to shopping mall/market.

|

Machinery description –

• Leafy vegetable cube making machine.

• This machine is PLC operated to make easy cubes. It is in SS 304.

• Adjustable bolts are given for level adjustment.

|

Cube forming station

• Hopper for opening, cleaning operation

• Easy change parts

• Cube making station

• Easy change parts design

• Plastic mould for easy alignment.

• Adjustable knives

• Pressing stroke adjustable

• Safety switches are provided at necessary openings.

• PLC operating program

• Mould sizes are custom build.

|

Vegetable water filtration system

• The vegetable water removed while pressing the block contains vegetable

properties is filtered and stored in freezer & used as a shining water

or vegetable water.

• Vegetable water can be poured/injected into the easy cube block as a media.

• Vegetable water preserving system

• Vegetable water can preserved in ice form or in cold water form in cooling system.

• The final vegetable cube is with vegetable water content

• Best quality product due to addition of vegetable water.

• Energy consumption saved due to improvement in freezing temp.

|

Complete Sets of Vegetable Processing Production Line.

1. Slicing

2. Washing

3. Sorting

4. Blanching

5. Cooling

6. Dewatering

7. Quick Freezing

8. Packaging

9. Sorting |

Silent Features

• No contamination of product

• Easy to operate

• Easy to clean

• Natural properties of vegetables are maintained.

• Preventive Maintenance of cleaning is done by regular time interval.

|

Pineapple Processing Machinery

Complete plant of pineapple processing equipment including following procedures, washing the fresh pineapple, peeling, extracting, Enzymatic Treatment , Filtration, Concentrating, sterilizing, filling process etc. The fresh mango can be processed into the transparent juice and cloudy juice, then packed into aseptic bags or PET bottle etc, achieving the purpose to export by container for further process or supermarket.Some Asian and South American countries are big exporters of pineapple products, mainly of canned pineapple, pineapple concentrate and fresh pineapple.

Complete plant of pineapple processing equipment including following procedures, washing the fresh pineapple, peeling, extracting, Enzymatic Treatment , Filtration, Concentrating, sterilizing, filling process etc. The fresh mango can be processed into the transparent juice and cloudy juice, then packed into aseptic bags or PET bottle etc, achieving the purpose to export by container for further process or supermarket.Some Asian and South American countries are big exporters of pineapple products, mainly of canned pineapple, pineapple concentrate and fresh pineapple.

Shiva Engineers sets up pineapple processing lines for pineapple concentrate and canned pineapple production. Both lines are normally combined as the best pineapple is used for canning and fresh distribution, and the juice becomes a byproduct of this process. Lower quality fresh pineapple is used for juice and pineapple concentrate production.

Complete sets of Pineapple Juice Production Line:

1 The processing capacity is varied from 1 tons/Hour to 10 tons/Hour.

2 The line can deal with similar characteristic of fruits.

3 Using efficient belt juice extractor to improve the juice

efficiency and the output percentage of pineapple.

4. Low-temperature vacuum evaporation 8 greatly reduce the flavor

substances and nutrient losses.

5. Tubular UHT sterilizer and aseptic filling machine, isolated from the

pollution of bacteria, ensure the safety of the food and extend the shelf

life of the product.

6. A complete set of production with self CIP system reduce the labour

intensity and ensure the high level sanitation.

|

Complete sets of Pineapple Juice Production Line:

1. Pineapple Washing Machine

2. Sorting Conveyor

3. Juice Extracting Machine

4. Belt Press, Vibroscreener

5. Pineapple Juice Mixing Tank / Enzymatic Treatment

6. Preheating Machine

7. Decanter or Centrifuge

8. Juice Evaporator

9. Juice Sterilization & Aseptic Filling Machine / Juice Bottle Filling

10. Pineapple Corer & Sizer

11. Pineapple Slicer / Pineapple Skin Stripper / Pineapple Tidbits

12. Can Reforming Unit |

Amla Processing Machinery

We specialize in the designing and manufacturing of amla processing machinery.

Complete lines and technology for amla processing as well as reliable service worldwide by our skilled engineering.

It is our goal to be of service to our customers as effectively as possible.Raw amlas are separated from roots and leaves.The amla is cleaned and separated from bad ginger.Cleaned amla are peeled and chopped and send to a soaking unit for a definite period.Soaked amla are dried in a specially designed dryer.Essential oils and oleoresin extracted from the amla.

We specialize in the designing and manufacturing of amla processing machinery.

Complete lines and technology for amla processing as well as reliable service worldwide by our skilled engineering.

It is our goal to be of service to our customers as effectively as possible.Raw amlas are separated from roots and leaves.The amla is cleaned and separated from bad ginger.Cleaned amla are peeled and chopped and send to a soaking unit for a definite period.Soaked amla are dried in a specially designed dryer.Essential oils and oleoresin extracted from the amla.

The dried gingers are then pulverized to make it powder and further are packed as per requirements.

Complete Sets of Amla Processing Production Line.

1. Amla Sorting Conveyor

2. Amla Washing

3. Blanching

4. Pulping5. Filtration

6. Storage Tank

7. Batch Mixing Cooker

8. Storage Tank

9. Filling & Packaging

Guava Processing Plant & Machinery

We manufacture and install Guava & Papaya processing plant & machinery for Guava Pulp / Papaya Pulp.

We supplied Guava processing equipments such as Guava washer, conveyor, crushing, pasteurization, evaporation, filling & packaging bottles & pouches.

Guava / Papaya processing line in cold-break and hot-break system starting from 2 to 20 ton/hour with different level of automation and different feeding systems.

We manufacture and install Guava & Papaya processing plant & machinery for Guava Pulp / Papaya Pulp.

We supplied Guava processing equipments such as Guava washer, conveyor, crushing, pasteurization, evaporation, filling & packaging bottles & pouches.

Guava / Papaya processing line in cold-break and hot-break system starting from 2 to 20 ton/hour with different level of automation and different feeding systems.

Can be used to make as Guava Pulp / Papaya Pulp in cans

The packaging product in cans, bottles, pouches, aseptic bag in drum

Capacity of the plant :- 0.5/1/2/5/10/15/20 Ton per hour.

Our lines are characterised from long-experience know-how, strong construction and energy saving.

Complete sets of Guava Pulp & Juice production line:

1. Washing Machine

2. Sorting Conveyor

3. Elevator

4. Crusher

5. Cold/Hot Break System

6. Tubular Preheater Pasteurizer

7. Pulping Machine

8. Vacuum Evaporator / Continuous / forced circulation evaporator

9. Filling Line-- Can Filling Machine / Bottle Filling Machine / Sachet filling Machine / Aseptic bag in drum filling machine

Apple / Pears / Passion / Strawberry Processing Machinery

The apple juice production line contains apple washing, cleaning, waxing, grading, packing and apple chopping, apple juice extracting, juice residues separating, juice concentrating and juice packing etc.

The apple juice production line contains apple washing, cleaning, waxing, grading, packing and apple chopping, apple juice extracting, juice residues separating, juice concentrating and juice packing etc.

The processing capacity can be ranged from 10 tons per hour

Our apple juice processing line can handle similar fruits with similar characteristics.

1. Automatic disinfection liquid concentration control system, effectively guarantee the sterilization effect and control the disinfection residue.

2. Efficient crusher improved the high output percentage of apples and pears.

3. Using efficient belt juice extractor to improve the juice efficiency and the output percentage.

4. Low-temperature vacuum evaporation 8 greatly reduce the flavor substances and nutrient losses.

5. Tubular UHT sterilizer and aseptic filling machine, isolated from the pollution of bacteria, ensure the safety of the food and extend the shelf life of the product.

6. A complete set of production with self CIP system reduce the labour intensity and ensure the high level sanitation.

Complete sets of Apple / Pears / Passion Juice / Beverages and soft drinks Production Line:

1. Fruit Conveyor

2. Fruit Washing Machine

3. Chopping Machine / Mash Preparation

4. Juice Extracting Machine-Belt Press, Vibroscreener

5. Juice Mixing Tank / Enzymatic Treatment

6. Separator: Disc centrifuge and Solid bowl centrifuge / Ultra filtration

7. Preheating Machine

8. Juice Evaporator

9. Juice Sterilization & Aseptic Filling Machine / Juice Bottle Filling

Capacity: - Min 500 Kg /Hr Max 10 Ton/Hr

Frozen Vegetable Processing Plant Machinery

FROZEN VEGETABLE MACHINERY

we are the leading manufacture of frozen vegetable processing plant.

The complete processing line is available from 500kg per hr to 10 ton per hr.

We provide complete plant with processing line, cold storage , Refrigeration and IQF.

The plant supplied by us are very cost effective and easy to handle with low maintain-ens cost.

The Process Includes Conveyer System, Podding, Recovery, Sorting , Washing, Blanching, Cooling, De watering, and Finally Inspection.

Vegetable Processing & Freezing Machinery

Vegetable Processing Machinery/ Fresh cutting dicing & freezing lines to make salad/Slicer/Cube Making Machinery.

It includes sorting, cleaning, blanching, cooling, freezing, packing & storage.

We use most modern technology equipments in vegetable processing machinery.

Leafy vegetables processing

Leafy vegetables can be sorted on sorting conveyor/ tables. Cleaning is done in vegetable washer; blanching & cooling is done in belt type conveyor/chamber

Extra water removed on shaker/dewatering machine.

Vegetable inspection & metal detection on conveyor if quantity is more/large; optical sorter

Can be used.

• Freezing by blast freezer/ IQF

• Packed into bags & stored in cold rooms.

• Transfer into refrigerated van to shopping mall/market.

|

Machinery description –

• Leafy vegetable cube making machine.

• This machine is PLC operated to make easy cubes. It is in SS 304.

• Adjustable bolts are given for level adjustment.

|

Cube forming station

• Hopper for opening, cleaning operation

• Easy change parts

• Cube making station

• Easy change parts design

• Plastic mould for easy alignment.

• Adjustable knives

• Pressing stroke adjustable

• Safety switches are provided at necessary openings.

• PLC operating program

• Mould sizes are custom build.

|

Vegetable water filtration system

• The vegetable water removed while pressing the block contains vegetable properties is filtered

and stored in freezer & used as a shining water or vegetable water.

• Vegetable water can be poured/injected into the easy cube block as a media.

• Vegetable water preserving system

• Vegetable water can preserved in ice form or in cold water form in cooling system.

• The final vegetable cube is with vegetable water content

• Best quality product due to addition of vegetable water.

• Energy consumption saved due to improvement in freezing temp.

|

Silent Features

• No contamination of product

• Easy to operate

• Easy to clean

• Natural properties of vegetables

are maintained.

• Preventive Maintenance of cleaning is

done by regular time interval.

|

Complete Sets of Vegetable Processing Production Line.

1. Slicing

2. Washing

3. Sorting

4. Blanching

5. Cooling

6. Dewatering

7. Quick Freezing

8. Packaging

9. Sorting |

Tomato Ketchup / Paste / Sauce Processing Plant & Machinery

We manufacture and install tomato processing plant & machinery for tomato Paste, Ketchup, Sauce.

We supplied tomato processing equipments such as Tomato washer, conveyor, crushing, pasteurization, evaporation, filling & packaging bottles & pouches.

Tomato paste processing line in cold-break and hot-break system starting from 2 to 20 ton/hour with different level of automation and different feeding systems of whole tomato.

Can be used to make as tomato puree tomato paste, tomato ketchup, tomato sauce and peeled tomato in cans.

The packaging product in cans, bottles, pouches, aseptic bag in drum

Tomato Ketchup / Paste / Sauce Processing Plant & Machinery

We manufacture and install tomato processing plant & machinery for tomato Paste, Ketchup, Sauce.

We supplied tomato processing equipments such as Tomato washer, conveyor, crushing, pasteurization, evaporation, filling & packaging bottles & pouches.

Tomato paste processing line in cold-break and hot-break system starting from 2 to 20 ton/hour with different level of automation and different feeding systems of whole tomato.

Can be used to make as tomato puree tomato paste, tomato ketchup, tomato sauce and peeled tomato in cans.

The packaging product in cans, bottles, pouches, aseptic bag in drum We are manufacturing & supplying complete mango processing machinery on turnkey basis for the production of mango pulp, juice & concentrated puree, as well as single machines to meet specific requirements.

We are manufacturing & supplying complete mango processing machinery on turnkey basis for the production of mango pulp, juice & concentrated puree, as well as single machines to meet specific requirements. Shiva Engineers supplies integral processing and packaging solutions for the dairy industry, from milk reception and transformation processes to filling and packaging solutions.

Shiva Engineers supplies integral processing and packaging solutions for the dairy industry, from milk reception and transformation processes to filling and packaging solutions. Beverages Lines from concentrate to Juice Packaging

Beverages Lines from concentrate to Juice Packaging We specialize in the designing and manufacturing of vegetable processing machinery.

We specialize in the designing and manufacturing of vegetable processing machinery. We supply batch or continuous type jam/marmalade making machinery.

We supply batch or continuous type jam/marmalade making machinery. Green Pea Processing Equipment

Green Pea Processing Equipment We specialize in the designing and manufacturing of Ginger processing machinery.

We specialize in the designing and manufacturing of Ginger processing machinery. Vegetable Processing & Freezing Machinery

Vegetable Processing Machinery/ Fresh cutting dicing & freezing lines to make salad/Slicer/Cube Making Machinery.

Vegetable Processing & Freezing Machinery

Vegetable Processing Machinery/ Fresh cutting dicing & freezing lines to make salad/Slicer/Cube Making Machinery. Complete plant of pineapple processing equipment including following procedures, washing the fresh pineapple, peeling, extracting, Enzymatic Treatment , Filtration, Concentrating, sterilizing, filling process etc. The fresh mango can be processed into the transparent juice and cloudy juice, then packed into aseptic bags or PET bottle etc, achieving the purpose to export by container for further process or supermarket.Some Asian and South American countries are big exporters of pineapple products, mainly of canned pineapple, pineapple concentrate and fresh pineapple.

Complete plant of pineapple processing equipment including following procedures, washing the fresh pineapple, peeling, extracting, Enzymatic Treatment , Filtration, Concentrating, sterilizing, filling process etc. The fresh mango can be processed into the transparent juice and cloudy juice, then packed into aseptic bags or PET bottle etc, achieving the purpose to export by container for further process or supermarket.Some Asian and South American countries are big exporters of pineapple products, mainly of canned pineapple, pineapple concentrate and fresh pineapple. We specialize in the designing and manufacturing of amla processing machinery.

Complete lines and technology for amla processing as well as reliable service worldwide by our skilled engineering.

It is our goal to be of service to our customers as effectively as possible.Raw amlas are separated from roots and leaves.The amla is cleaned and separated from bad ginger.Cleaned amla are peeled and chopped and send to a soaking unit for a definite period.Soaked amla are dried in a specially designed dryer.Essential oils and oleoresin extracted from the amla.

We specialize in the designing and manufacturing of amla processing machinery.

Complete lines and technology for amla processing as well as reliable service worldwide by our skilled engineering.

It is our goal to be of service to our customers as effectively as possible.Raw amlas are separated from roots and leaves.The amla is cleaned and separated from bad ginger.Cleaned amla are peeled and chopped and send to a soaking unit for a definite period.Soaked amla are dried in a specially designed dryer.Essential oils and oleoresin extracted from the amla. We manufacture and install Guava & Papaya processing plant & machinery for Guava Pulp / Papaya Pulp.

We supplied Guava processing equipments such as Guava washer, conveyor, crushing, pasteurization, evaporation, filling & packaging bottles & pouches.

Guava / Papaya processing line in cold-break and hot-break system starting from 2 to 20 ton/hour with different level of automation and different feeding systems.

We manufacture and install Guava & Papaya processing plant & machinery for Guava Pulp / Papaya Pulp.

We supplied Guava processing equipments such as Guava washer, conveyor, crushing, pasteurization, evaporation, filling & packaging bottles & pouches.

Guava / Papaya processing line in cold-break and hot-break system starting from 2 to 20 ton/hour with different level of automation and different feeding systems. The apple juice production line contains apple washing, cleaning, waxing, grading, packing and apple chopping, apple juice extracting, juice residues separating, juice concentrating and juice packing etc.

The apple juice production line contains apple washing, cleaning, waxing, grading, packing and apple chopping, apple juice extracting, juice residues separating, juice concentrating and juice packing etc.