Vegetable Processing Equipment

Our range of products include Vegetable Processing Equipment such as Blancher, Vibratory Shaker, Pea Podder, Elevator, Pea Peeling Machine and Vegetable Washer.

Blancher

Fruit & Vegetable Blancher

Fruit & Vegetable Blancher

Capacity up to 10000 kg/hr or 10 T/hr

To blanch the fruit and vegetable by means of hot water.

This treatment is used, generally, to inactivate some specific enzymes that can damage the product in the following phases of workmanship.

The product is carried by a belt conveyor whose speed is adjustable by manual speed reducer to optimize the processing times according to the production needs.

An automatic system verify the water temperature and drive the heating system made by a steam group

The main components of the blancher are:

Belt for supporting the product;

Electrical gear motor with variable speed;

Group for producing hot water and recirculation in the heat exchanger;

Control panel.

Vibratory Shaker

Vibratory Shaker / Water Removing Unit / Dewatering Unit

Vibratory Shaker / Water Removing Unit / Dewatering Unit

Mounted on both sides of frame.

Complete Unit is mounted on Springs.

Vibrator is Kept on M.S. / S.S sq Tube Frame.

Excess water is removed from the product.

Perforated Vibrating screen Unbalanced vibratory motors are used for removing the excess surface water with shaking.

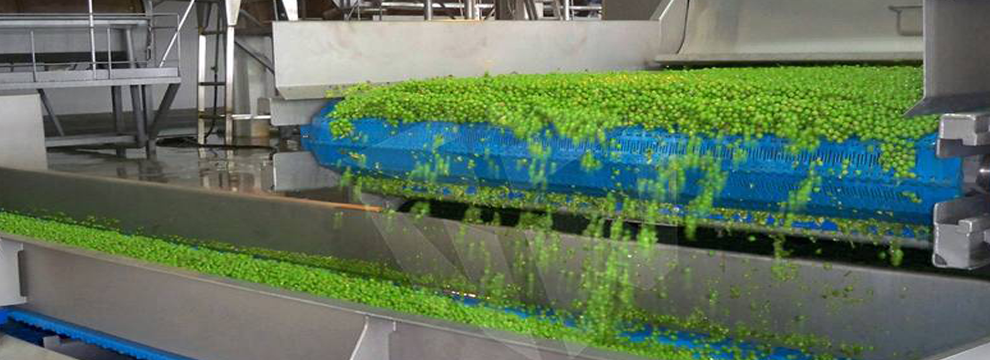

Pea Podder

We can provide complete Pea lines for the processing of green peas, -IQF for capacities between 1 and 5 tons/hr. Our experience includes solutions for all steps of the processing of podded raw material:

We can provide complete Pea lines for the processing of green peas, -IQF for capacities between 1 and 5 tons/hr. Our experience includes solutions for all steps of the processing of podded raw material:

Suitable for separation of grains from the pods.

Machine, rotor, beater blades etc; are made out of S.S.304.

Conveyor is fitted with S.S rollers, flanged bearing on one side

and take-up bearing on the other side for tensioning.

The apron conveyor belt is made out of food grade PVC quality.

The conveyor belt is endless.

The liners, guards, covers, hoppers, etc. are made out of S.S. 304.

Reliability of vegetable processing machines, hygiene, precision and a long life.

Elevator

We manufacture a comprehensive range of bucket elevator, which are highly effective in elevating and discharging different types of fruits and vegetables from the end of one process equipment to the beginning of next. These bucket elevators are effective for mangoes, apples, guavas, citrus etc.

We manufacture a comprehensive range of bucket elevator, which are highly effective in elevating and discharging different types of fruits and vegetables from the end of one process equipment to the beginning of next. These bucket elevators are effective for mangoes, apples, guavas, citrus etc.

1. Flight Elevator

Features

Capacity: up to 5000 kg per hour depending upon type, size and nature of product.

Pea Peeling Machine

We can provide complete Pea lines for the processing of green peas, -IQF for capacities between 1 and 5 tons/hr. Our experience includes solutions for all steps of the processing of podded raw material:

Suitable for separation of grains from the pods.

Machine, rotor, beater blades etc; are made out of S.S.304.

Conveyor is fitted with S.S rollers, flanged bearing on one side and take-up bearing on the other side for tensioning.

The apron conveyor belt is made out of food grade PVC quality.

The conveyor belt is endless.

The liners, guards, covers, hoppers, etc. are made out of S.S. 304.

Reliability of vegetable processing machines, hygiene, precision and a long life.

We can provide complete Pea lines for the processing of green peas, -IQF for capacities between 1 and 5 tons/hr. Our experience includes solutions for all steps of the processing of podded raw material:

Suitable for separation of grains from the pods.

Machine, rotor, beater blades etc; are made out of S.S.304.

Conveyor is fitted with S.S rollers, flanged bearing on one side and take-up bearing on the other side for tensioning.

The apron conveyor belt is made out of food grade PVC quality.

The conveyor belt is endless.

The liners, guards, covers, hoppers, etc. are made out of S.S. 304.

Reliability of vegetable processing machines, hygiene, precision and a long life.

Vegetable Washer

We offer complete and continuous washing line for fruits and vegetables to be processed in puree and or juice.

We offer complete and continuous washing line for fruits and vegetables to be processed in puree and or juice.

Capacity from 0.15mt/hr to 20 mt/hr for the continuous lines.

Washing system completely manufactured in AISI 304 stainless steel and equipped with blower.

Sorting line with belt or rollers equipped with motor variator to adjust the speed

We also produce batch type washing unit for small production capacity.

The main components of the washer are:

• S.S Tank

• P.P/S.S Belt

• Pump

• Gearbox & Motor

• Bearing

• Special nozzles for fresh water spray

• Overflow drum

Fruit & Vegetable Blancher

Fruit & Vegetable Blancher Vibratory Shaker / Water Removing Unit / Dewatering Unit

Vibratory Shaker / Water Removing Unit / Dewatering Unit We can provide complete Pea lines for the processing of green peas, -IQF for capacities between 1 and 5 tons/hr. Our experience includes solutions for all steps of the processing of podded raw material:

We can provide complete Pea lines for the processing of green peas, -IQF for capacities between 1 and 5 tons/hr. Our experience includes solutions for all steps of the processing of podded raw material: We manufacture a comprehensive range of bucket elevator, which are highly effective in elevating and discharging different types of fruits and vegetables from the end of one process equipment to the beginning of next. These bucket elevators are effective for mangoes, apples, guavas, citrus etc.

We manufacture a comprehensive range of bucket elevator, which are highly effective in elevating and discharging different types of fruits and vegetables from the end of one process equipment to the beginning of next. These bucket elevators are effective for mangoes, apples, guavas, citrus etc. We can provide complete Pea lines for the processing of green peas, -IQF for capacities between 1 and 5 tons/hr. Our experience includes solutions for all steps of the processing of podded raw material:

Suitable for separation of grains from the pods.

Machine, rotor, beater blades etc; are made out of S.S.304.

Conveyor is fitted with S.S rollers, flanged bearing on one side and take-up bearing on the other side for tensioning.

The apron conveyor belt is made out of food grade PVC quality.

The conveyor belt is endless.

The liners, guards, covers, hoppers, etc. are made out of S.S. 304.

Reliability of vegetable processing machines, hygiene, precision and a long life.

We can provide complete Pea lines for the processing of green peas, -IQF for capacities between 1 and 5 tons/hr. Our experience includes solutions for all steps of the processing of podded raw material:

Suitable for separation of grains from the pods.

Machine, rotor, beater blades etc; are made out of S.S.304.

Conveyor is fitted with S.S rollers, flanged bearing on one side and take-up bearing on the other side for tensioning.

The apron conveyor belt is made out of food grade PVC quality.

The conveyor belt is endless.

The liners, guards, covers, hoppers, etc. are made out of S.S. 304.

Reliability of vegetable processing machines, hygiene, precision and a long life. We offer complete and continuous washing line for fruits and vegetables to be processed in puree and or juice.

We offer complete and continuous washing line for fruits and vegetables to be processed in puree and or juice.