Overview

Air-Cooled Steam Condenser is required to condense the exhaust steam from the turbine into the condenser at constant pressure and temperature and required to maintain the backpressure at the turbine exhaust flange.

What is an Air-Cooled Steam Condenser?

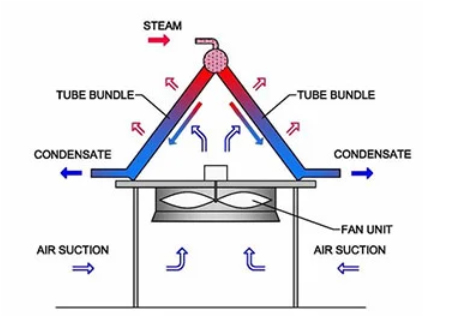

Air-Cooled Steam Condenser comprises of tube bundles with Circular/Flat/Elliptical finned tubes fixed at a height of an 'A' or 'V' frame structure at an angle of 60 Deg. Axial flow fans mounted at the lower vertex of the 'A' or 'V' frame throw the cooler air at ambient temperature into the 'A' or 'V' frame. When the air passes through the finned tube bundles it will cool the fluid inside the finned tubes or condenses the steam inside the tube by reducing the latent heat of steam.

Components of Air-Cooled Steam Condenser

Air Cooled Condenser comprises cells/modules/bays. Each cell consists of the following major equipment :

- Steam manifold/steam duct from turbine exhaust flange to the Air Cooled Condenser

- A frame structure supporting the tube bundles

- Axial Flow Fans arrangement with gear box and motor

- Condensate & hotwell tank with pumps

- Ejector for extraction of the non condensable gases from the tube bundles

- Piping with valves and instruments as per the requirement

- Instrumentation and electrical as per the Air Cooled Condenser operational philosophy