Our Products

- Blue Tack Nails

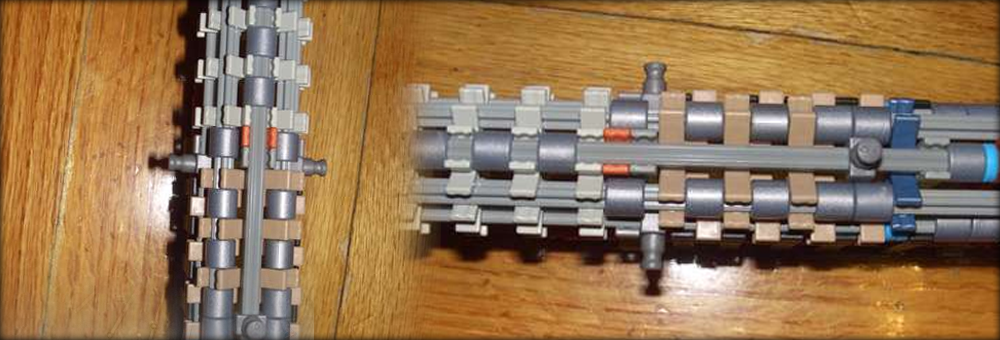

- Cage Bars & Cage Bar Holders

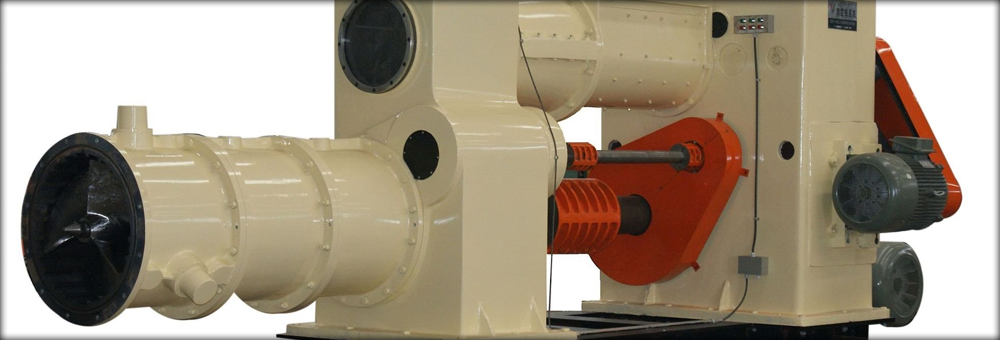

- Chamber Barrel

- Cone Point

- Filter Presses

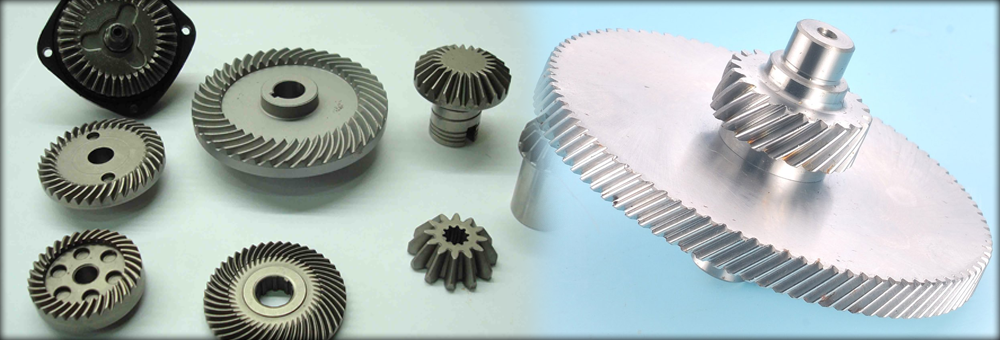

- Gears For De Airing Pug mill

- Industrial Conveyors & ConveyorFasteners

- Nails For Up Holstery

- Pressing Worms & Collars

- Spur Bevel Gears & Pinions

- Worm Shaft & Side Shaft

Contact Us

Allied Expeller Industries

Contact Person

Mr. Puneet Gaur

Telephone: +(91)-(161)-2532414 /

2440085

Mobile : +(91)-9779912414

Fax No: +(91)-(161)-2532414

Address: No. 11811, S. A. S. Nagar, Ludhiana, Punjab - 141 003 (India)

About Us

With the expertise of years, our company is engrossed in the manufacturing & supplying of oil expeller spare, expeller spare parts, filter presses, bevel gears, industrial conveyors, conveyor fasteners, industrial conveyor fasteners and belt conveyor fasteners. Our innovative techniques and technology enables us to produce high performance machines at most reasonable prices. Made as per the international standards, our range of products are known for their qualitative features. We work step by step from the very starting of generating of concepts, designing & development to project management.

Our ability to match our range of products as per the demands of markets allows us to produce innovative, high performance machines at most competitive prices. Our company is based on the foundation of dedication & hard work , which results in success of our company over the years. We have earned this fame through our highly motivated staffs, state-of-the-art infrastructure and quality centric approach.

Our After Sales Support

Besides manufacturing & supplying qualitative range of oil expeller spare parts, we also provide effective after sales support, which consists of various services, such as

- Revamping of existing machine

- Training on the installation

- Maintenance of components & many more

Our Products Range

The best possible use of latest & innovative technology enable us to manufacture qualitative range of expeller spare parts. With the aim of providing quality parts at competitive prices, we are deeply involved in the production of quality oil expelled machine parts. These machine parts are cater to different segments including seeds industry, vegetables industry and others. Some of our range of machines are expeller spares, oil expeller spare parts, blue tack nails, gears, oil mill machinery spare, filter presses, bevel gears, Industrial conveyors, conveyor fasteners. industrial conveyor fasteners and belt conveyor fasteners. The quality centric approach of our company helps in maintaining the quality at every steps. The raw materials are procured from the reliable & quality conscious suppliers. This enables us to deliver machines with high quality with strong features.

Some of them are:

- Easy Operation

- Low Maintenance

- Saves electricity

- Occupy less space

- High Effective

- Reliable

- High Tolerance

Our Customization Facility

Our company give prime concern on our customer's specific requirements and thus provide them machines in accordance with their requirements. We place orders & manufacture customized products in the terms of size, shape, design, functionality etc, in order to fulfill their specific needs with utmost precision. This not only solve out customers purpose, but also helps us to show our innovative product range.

Our Strengths

- Satisfy customers

- Minimum wear and tear

- Low electricity consumption

- Low maintenance machines

- High oil productivity

- Low space occupancy

- Continuous Research & Development

- Delivery on time

Our Quality Compliance

Following the quality centric approach, our company is fully involved in delivering high quality machines & spare parts. With the understanding of our clients' requirements, we follow the international parameters of quality, which enables us to mark ourselves as a quality centric company. Procurement of the raw products from the best available sources at competitive prices to the final delivery of the machines helps us in our quality compliance.

We also maintain our quality compliance by ensuring the quality check before dispatching along with safety measures to ensure quality during transit. For maintaining the whole procedures of our quality, we are constantly testing new designs, methods and materials to anticipate our customers needs. We have the facility of long-term research, identifying emerging technologies and developing the anticipated machines to ensure quality at every steps.

Our Workforce

We have a pool of highly qualified engineers who are capable of undertaking the various jobs of our company. The talented team of our service engineers helps us in installing and providing efficient after sales services to our clients thus ensuring smooth operations. The team is dedicated towards their nature of job so as to provide satisfactory services to our clients.

Our company also maintain a good working environment for our efficient team, which enables them to work smoothly. They are also given internal trainings so as to make them update according to the changes in the market. Apart from this, internal refreshment occasions are organized to boost them up for their work.

Our Infrastructure

A well equipped infrastructure including skilled technicians, quality control personnel, dedicated workers and latest precision machinery helps us to churn out our work in most efficient manner for our clients. The quality personnel also plays an important role by inspecting & checking the various works including the whole manufacturing processes in detail. They inspect from low to top level thus ensuring our clients the best products range.

Manufacturing Unit

The manufacturing processes of our company goes under the following steps:

- Oil expeller being assembled

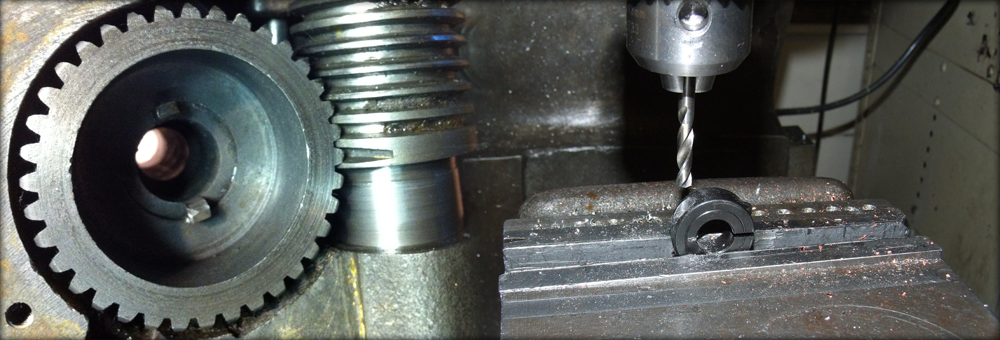

- Worm manufacturing

- Gears

- Cage Bar finishing

The workshop of our company have the following units:

- Oil expeller Unit

- Blue-Tak-Nails Unit