CASTING FACILITIES

Allied products have the manufacturing, machining and testing facilities. This allows us to carry out different operations that are needed under one roof. We have latest and upgraded machineries which are from renowned companies.

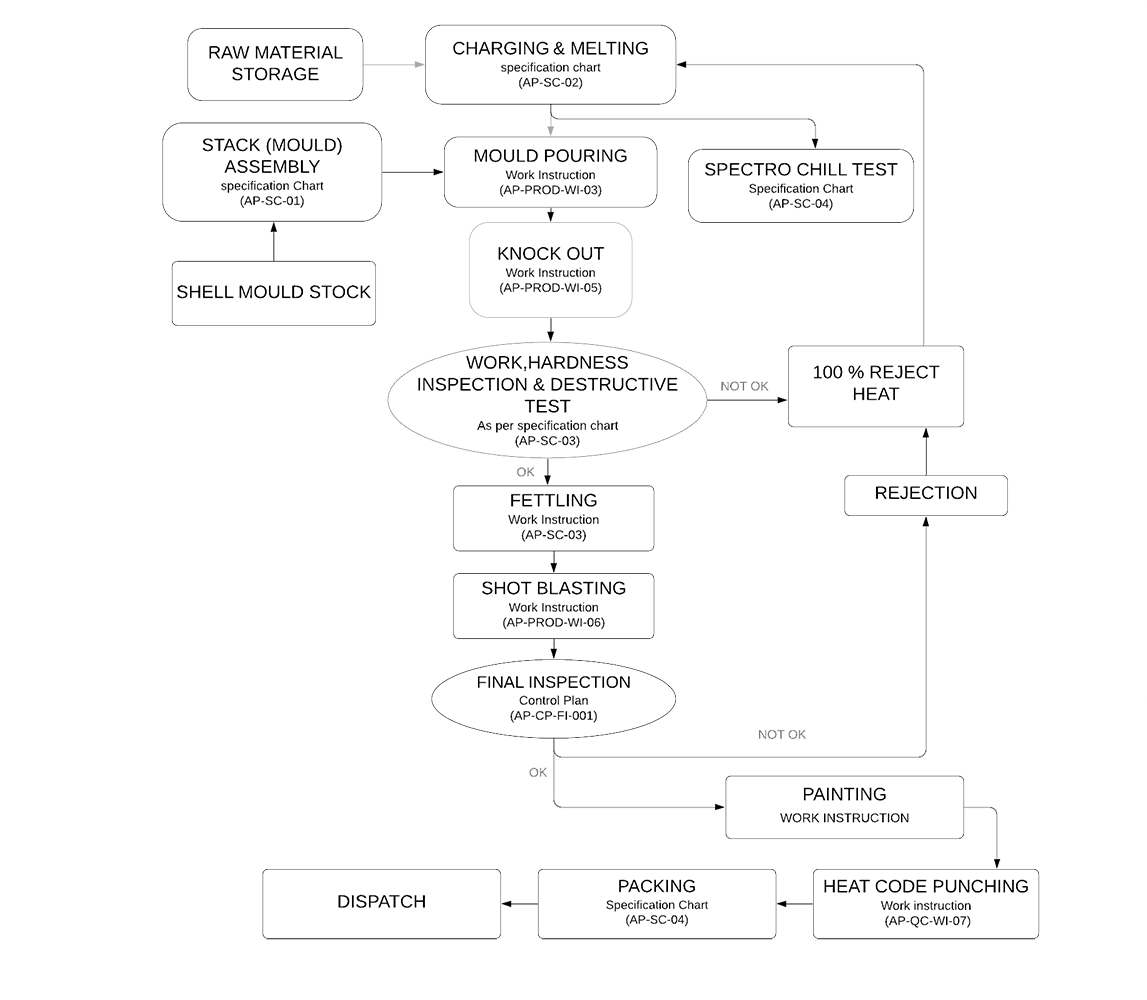

To form the casting and develop a product under shell moulding we have following systems.

- 3 independent coreless Induction Furnaces of 300 Kg /100 Kg /100 Kg. capacity.

- Spectro Meter & C.E. Meter.

- Compact molten metal pouring system.

- Moulds are stacked together & poured to get castings.

- Tumbler type shot blasting and Table type shot blasting machines

- Pedestal grinders, bench grinders and deburrers

- Optical type Brinell hardness testers

- Microscope with image analyzing software

- Measurement Instrument

- Painting / Oiling

- Automatic Heat Code Marking Machines.

Material Grades Of Gray Cast Iron

| Country | Standard | Equivalent Grades of Gray Iron (Grey Cast Iron) | ||||||

| ISO | ISO 185 | 100 | 150 | 200 | 250 | 300 | 350 | — |

| China | GB 9439 | HT100 | HT150 | HT200 | HT250 | HT300 | HT350 | — |

| USA | ASTM A48 | — | NO.20 | NO.30 | NO.35 | NO.40 | NO.50 | NO.55 |

| NO.25 | NO.45 | NO.60 | ||||||

| Germany | DIN 1691 | GG10 | GG15 | GG20 | GG25 | GG30 | GG35 | GG40 |

| Austria | ||||||||

| European | EN 1561 | EN-GJL-100 | EN-GJL-150 | EN-GJL-200 | EN-GJL-250 | EN-GJL-300 | EN-GJL-350 | |

| Japan | JIS G5501 | FC100 | FC150 | FC200 | FC250 | FC300 | FC350 | — |

| Italy | UNI 5007 | G10 | G15 | G20 | G25 | G30 | G35 | — |

| France | NF A32-101 | — | FGL150 | FGL200 | FGL250 | FGL300 | FGL350 | FGL400 |

| UK | BS 1452 | 100 | 150 | 200 | 250 | 300 | 350 | — |

| India | IS 210 | — | FG150 | FG200 | FG260 | FG300 | FG350 | FG400 |

| Spain | UNF | — | FG15 | FG20 | FG25 | FG30 | FG35 | — |

| Belgium | NBN 830-01 | FGG10 | FGG15 | FGG20 | FGG25 | FGG30 | FGG35 | FGG40 |

| Australia | AS 1830 | — | T150 | T220 | T260 | T300 | T350 | T400 |

| Sweden | SS 14 01 | O110 | O115 | O120 | O125 | O130 | O135 | O140 |

| Norway | NS11 100 | SJG100 | SJG150 | SJG200 | SJG250 | SJG300 | SJG350 | — |

Material Grades Of Ductile Cast Iron

| Country | Standard | Equivalent Grades of Ductile iron (SG Iron, Nodular Graphite Iron) | ||||||

| ISO | ISO 1083 | 400-15 | 450-10 | 500-7 | 600-3 | 700-2 | 800-2 | 900-2 |

| 400-18 | ||||||||

| China | GB 1348 | QT400-18 | QT450-10 | QT500-7 | QT600-3 | QT700-2 | QT800-2 | QT900-2 |

| USA | ASTM A536 | 60-40-18 | 60-42-10 | 70-50-05 | 80-55-06 | 100-70-03 | 120-90-02 | — |

| 65-45-12 | 80-60-03 | |||||||

| Germany | DIN 1693 | GGG40 | — | GGG50 | GGG60 | GGG70 | GGG80 | — |

| Austria | ||||||||

| European | EN 1563 | EN-GJS-400-15 | EN-GJS-450-10 | EN-GJS-500-7 | EN-GJS-600-3 | EN-GJS-700-2 | EN-GJS-800-2 | EN-GJS-900-2 |

| EN-GJS-400-18 | ||||||||

| Japan | JIS G5502 | FCD400 | FCD450 | FCD500 | FCD600 | FCD700 | FCD800 | — |

| Italy | UNI 4544 | GS370-17 | GS400-12 | GS500-7 | GS600-2 | GS700-2 | GS800-2 | — |

| France | NF A32-201 | FGS370-17 | FGS400-12 | FGS500-7 | FGS600-2 | FGS700-2 | FGS800-2 | — |

| UK | BS 2789 | 400/17 | 420/12 | 500/7 | 600/7 | 700/2 | 800/2 | 900/2 |

| India | IS 1865 | SG370/17 | SG400/12 | SG500/7 | SG600/3 | SG700/2 | SG800/2 | — |

| Spain | UNF | FGE38-17 | FGE42-12 | FGE50-7 | FGE60-2 | FGE70-2 | FGE80-2 | — |

| Belgium | NBN 830-02 | FNG38-17 | FNG42-12 | FNG50-7 | FNG60-2 | FNG70-2 | FNG80-2 | — |

| Australia | AS 1831 | 300-17 | — | 500-7 | 600-3 | 700-2 | 800-2 | — |

| 400-12 | ||||||||

| Sweden | SS 14 07 | 0717-02 | — | 0727-02 | 0732-03 | 0737-01 | 0864-03 | — |

| Norway | NS11 301 | SJK-400.3 | — | SJK-500 | SJK-600 | SJK-700 | SJK-800 | |

| SJK-400 | ||||||||