SPECIAL AUTOMATION MACHINES

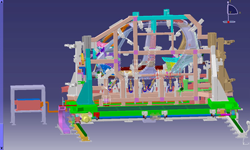

FRAME PROJECTION WELDING CNC SPM

CNC Automation Machines for spot welding 80 Arm Welders Variants with 40 Secs Cycle time

Common Fixture for ALL Variants

Multi Axis spot welding SPM

Multi Axis Spot welding SPM

Spot Welding SPM With Indexer

Spot Welding SPM With Indexer

ROBOT GUN ON SINGLE AXIS SLIDE MOVEMENT

DUAL AXIS SPOT WELDING SPM

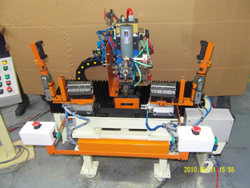

NUT WELDING AUTOMATION MACHINE

NUT WELDING AUTOMATION MACHINE

2 STUD + 7 X M6 NUT + 1 X M8 NUT

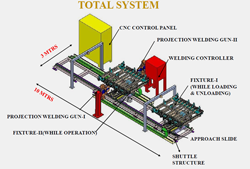

PROJECTION WELDING SPM

• COMPONENT SLIDE MOVEMENT –

1500 MM FROM LOADING TO

WELDING ON LM GUIDE WITH BALL

RAIL SYSTEM

• UNIQUE CLAMPING SYSTEM TO

REDUCE POWER / CABLE

CONSUMABLE CONSUMPTION

• PLC CABINET PANEL –

MITSUBISHI – FX2N SERIES

56 INPUT / OUTPUT

• TUNGSTEN COPPER ELECTRODES

• CYCLE TIME ACHIEVED – 50 SECS

WITH COMPONENT LOADING /

UNLOADING

SERIES WELDING SPM FOR LOAD BODY

DUAL HEAD SERIES WELDING GUN

DUAL HEAD SERIES WELDING GUN

• RATING - 100 KVA

• WELDING CURRENT – 16 KA

• FORCES – 350 Kgf INDEPENDENT ON

EACH WELDING TIP

• X – Y AXIS MOVEMEMENT

• 3 DIFFERENT MACHINES FOR

- LOAD BODY FRAME WELDING 220 SPOTS

- SIDE PANEL REINFORCEMENT 100 SPOTS

- SIDE PANEL WELDING 100 SPOTS

• WELDING STROKE FOR 25 MM WITH

150 MM RETRACT OPENING

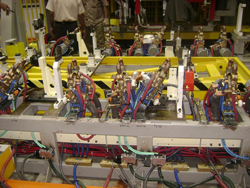

FIXTURE GUN MULTI SPOT WELDING SPM

FIXTURE GUN MULTI SPOT WELDING SPM

• 6 LH + 6 RH FIXTURE GUNS FOR

FRAMING STATION – 1

• 4 LH + 4 RH FIXTURE GUNS FOR

FRAMING STATION 2

• TRANSFORMER – 200KVA

• WELDING CURRENT – 12 KA

• FORCE ON EACH GUN – 350 Kgf

• PLC CABINET PANEL –

ALLEN BRADELY COMPACT LOGIX

64 INPUT / OUTPUT

ETHERNET COMMUNICATION WITH

LINE PLC

• WELDING CONTROLLER

• SCOPE INCLUDED REDESIGN AND

MODIFICATION OF FIXTURE SUB –

ASSY, INSTALLATION,

COMMISSIONING AND PROVING