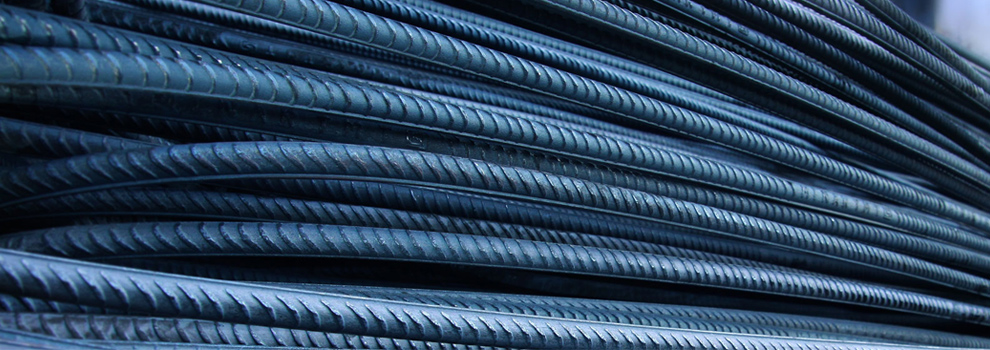

Thermex Properties

| Nominal Size* (mm) |

Nominal Section Wt. (Kg/M) |

Section Weight (range) (Kg/M) |

| 8 |

0.395 |

(0.367 – 0.423) |

| 10 |

0.617 |

(0.574 – 0.660) |

| 12 |

0.888 |

(0.844 – 0.932) |

| 16 |

1.58 |

(1.501 – 1.659) |

| 20 |

2.47 |

(2.396 – 2.544) |

| 25 |

3.85 |

(3.734 – 3.966) |

| 28 |

4.83 |

(4.685 – 4.975) |

| 32 |

6.31 |

(6.121 – 6.499) |

Chemical Composition Thermex bars, unlike CTD bars, have a proven record resisting loss of strength at high temperatures as experienced during fires.

Bend Properties Easily satisfy International Standards. In India Bend 8 Rebend Tests are mainly carried out as per Indian 1786 8 British 4449 standards. BHAGWATI THERMEX bars meet all such requirements.

| Test |

IS 1786 Fe 415 |

Bhagwati TMX - 400 |

BS 4449 Gr.460 |

Bhagwati TMX - 450 |

IS 1786 Fe 500 |

Bhagwati TMX - 500 |

| Bend |

3d (4d for>22 dia) |

2d |

3d |

2d |

4d (5d for>22dia) |

3d |

| Rebend |

5d (7d for>10 dia) |

4d |

5d |

4d |

5d (7d for>10dia |

5d |

Weldability Bhagwati Thermex bars are produced with C less than 0.25% an are suitable for all the main welding processes without any special precautions. No pre-heating or post-heating is necessary. No loss of strength at weld- joints.

Strain Ageing Ageing resistant due to the manufacturing process and chemica composition.

Fatigue Approved internationally for dynamically stressed structural sections.

Properties at High Temperatures Thermex bars, unlike CTD bars, have a proven record resisting loss of strength at high temperatures as experienced during fires.

Corrosion Resistance More corrosion resistant than CTD bars. Cold working involved in CTD bars leads to surface stresses and consequent higher rate of corrosion - and, the protective scale layer falls off during twisting The Thermex process basically inhibits rate of scale formation and no cold working is involved.

Thermex Grades

| Bhagwati Thermex / Tempcore 415M |

| Properties |

Standard IS 1786, Fe 415 |

Bhagwati |

| Yield Strength, N/mm2, min |

415 |

430 - 460 |

| Tensile Strength, N/mm2, min |

485 |

500 - 570 |

| Stress Ratio (TS/YS), min |

1.13 |

1.15 - 1.25 |

| Elongation, % min’ |

14.5 |

20 - 24 |

| Bhagwati Thermex / Tempcore 500 |

| Properties |

Standard IS 1786, Fe 500 |

Bhagwati |

| Yield Strength, N/mm2, min |

500 |

520 - 550 |

| Tensile Strength, N/mm2, min |

560 |

590 - 570 |

| Stress Ratio (TS/YS), min |

1.10 |

1.15 - 1.24 |

| Elongation, % min’ |

12 |

18 - 12 |

Thermex Benefits

- Lowers Steel Consumption

- International Steel consumption quality product at local affordable prices

- High weldability and ductility

- High yield strength with high elongation

- High thermal stability

- Ease of availability

- Better corrosion resistance

- Higher Grades easily available ( Fe 400, Fe 400D, Fe 500, Fe 500D, Fe 550, Fe 550D)

- Better resistance of fatigue

- Higher bond strength

- Higher resistance to strain Aging

- Availability of International grades

- Ease of use leading to less construction time

- Most suited for seismic zones as nearly 60% of India falls in high seismic hazard category

Technology

The last few decades has witnessed a demand for low-cost reinforcement bars of higher yield strength viz 450 N/mm2 (as in UK) or 500 N/mm2 (Germany Switzerland, France etc.). Cold twisting and other means such as raising carbo content directly affected the elongation and ductility and hence were found unacceptable. Technological advance such as the 'state-of-art' THERMEX thermo-processing treatment have enabled production of desired high strength rebars that meet all requirements of civil construction - yield strength ranging from 450 to 550 N/mm2 or more toughness, high elongation value and ductility, weldability, excellent bend properties etc.

A short, intensive but very precise in-line cooling of the rolled bar is imparted in THERMEX process through proprietary system. This treatment results in a cooled hardened periphery. On further cooling of the bar in atmosphere a Thermal exchange (THERMEX) occurs between the core and cooled outside martensite surface where by the resultant bar structure is a distinct tempered martensite at periphery and a fine grained ferrite - pearlite structure in the central zone.

The BHAGWATI THERMEX BAR produced as above have unique qualities of desired high strength and toughness combined with excellent ductility with bars having elongation (A5) values of 18 to 25%.

Comparison

| Bhagwati Thermex / Tempcore Bar Vs Others |

| Properties |

Duplicate TMT |

CTD bars/TOR |

Main Producers |

Bhagwati |

| Strength |

Lower than CTD/TOR |

Avg (Normally upto Fe 415 grade) |

High (Grade Fe 500 is easily available) |

High (Grade Fe 500 is easily available) |

| Elongation |

Non - standard |

Approx 14.5% |

High |

High; 18 - 25% in all grades |

| Weldability |

Very Weak |

Weak |

Better & more strength |

Better & more strength |

| Formability |

Non - standard |

Average |

Excellent due to uniform elongation |

Excellent due to uniform elongation |

| Technology |

Unscientific method |

Indian |

Tempcore/ Thermex (Belgium / German) |

Tempcore/ Thermex (Belgium / German) |

| Ductility & Fatigue Strength |

Non - standard |

Average |

High |

High-most appropriate for earthquake prone areas |

| Corrosion Resistance |

Very low |

Low |

High |

High |

| Ribs |

Manual & Non-uniform |

Manual & Non-uniform |

Computerised & Uniform |

Computerised & Uniform |

| Savings |

Very High Steel consumption due to

unscientific methods |

Nil |

No saving due to higher prices |

8-15% compared to CTD bars / Main Producers |

| Availability |

Non - Consistent |

Available |

Irregular Supply |

Easily available through network |

| Price |

Very cheap due to low quality |

Cheap due to outdated technology |

Very high Price for the same Quality |

Much lower than main producers for the same quality |