APPLICATION:

The addition rate of MAGREMOVER- POWDER S is vary and depend upon the initial level of Mg content and % of Magnesium to be removed. Spread MAGREMOVER –POWDER S flux on the molten metal surface uniformly. During addition rabble the melt uniformly along-with MAGREMOVER –POWDER S. After complete addition of flux hold material for 20 minutes in the furnace keeping burner on low flame. After completion of reaction again rabble the melt uniformly, remove the dross and analyse the melt for Mg content, and carry out further treatment if necessary.

It is recommended to add 7-10 kg MAGREMOVER POWDER S to remove 1 kg of

Magnesium from molten metal, for melt having initial Mg content 0.5% and above.To

remove Mg from molten metal having lower percentage of Mg i.e. below 0.4%,

MAGREMOVER- POWDER S addition increases and it may goes up to 10-14 kg to remove 1 kg of magnesium from molten metal. This can be further assisted by lancing the melt with Nitrogen / Argon. MAGREMOVER-POWDER S can also be injected below the molten metal surface to further improve the efficiency of the treatment.

With addition of flux for Magnesium removal calcium also get removed, hence different dosage level is not recommended.

Note: However during bulk usage it is observed that requirement of MAGREMOVER-POWDER S varied from 8-16 kg to remove 1 kg Mg. Shop floor conditions , skill of operator, molten metal temperature and treatment process is not in our control. End user to standardize their process to get best output from

our product.

APPLICATION TEMPERATURE: 740-760°C

BENEFITS –

Can be used as Surface treatment or with Flux Injection Machine.

Free from pungent smell and heavy smoke.

Environmental friendly.

25-30% reduction in dross formation compared to Chlorine based tablet form Mg

removal products.

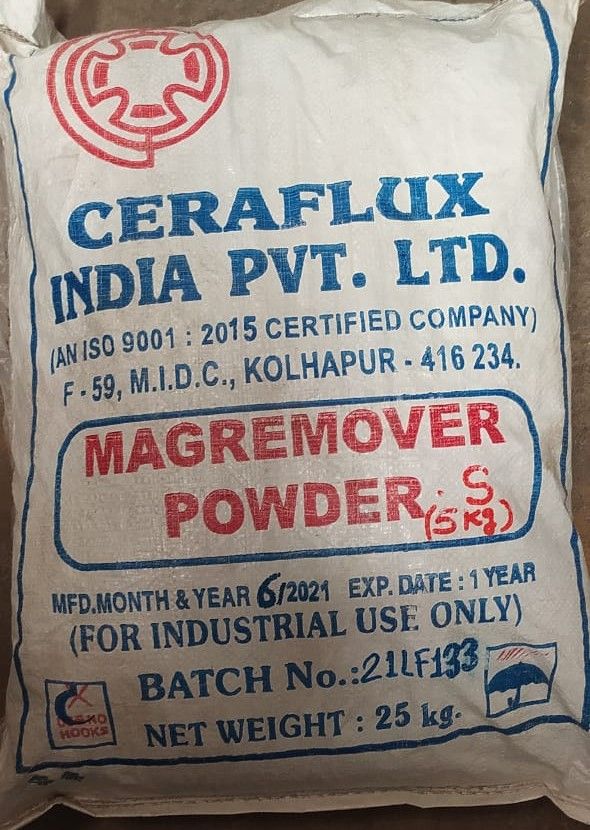

STANDARD PACKING: 5,10 kg Polyethylene bags packed in 20/50 kg HDPE bags.

STORAGE: Store in cool and dry place and away from direct heat.

SHELF LIFE: 12 months from date of manufacturing.

PRECAUTION: FLUX IS HYGROSCOPIC IN NATURE SO STORE IT IN DRY ATMOSPHERE.