Jigs and Fixtures

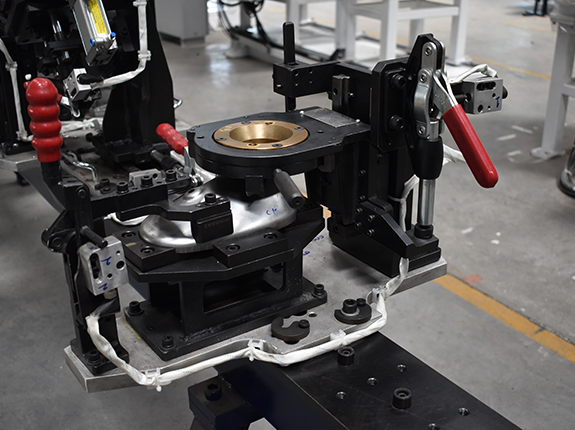

We also Designed, manufactured various type of JIGs and Fixture for automotive industries. We use standard products such as toggle clamps, pneumatic clamps etc for proper & accurate holding the components.

- Manual & Robotic MIG/SPOT/TIG Welding Fixtures

- Inspection and Checking Gauges

- Complete Turnkey solutions for manual & exhaust welding line

BIW WELD LINE:

BIW is included in the following parts:

Under body: Under body forms the basis of Body In White, it is involving sub-assembly of engine room, front room and rear floor which put together and assembled through each small parts.

Upper body: The Upper Body is composed of Sub-complete assemblies such as Side Frame (body) L/R, Roof Panel, Cowl & Dash and Package Tray.

Main body: Main body is the core production of automotive body manufacture to assembly (weld) and set Under Body and Upper Body is included Side Body, Cowl & Dash, Package Tray and Roof Panel.

MIG WELDING FIXTURE:

We also Designed, manufactured various type of MIG Welding fixture for automotive industries. We use standard products such as toggle clamps, pneumatic clamps etc for proper & accurate holding the components.

We have provided complete welding solution including sequential process – complete Turn Key following Segments Weld Lines.

2 WH-Frame and Child Part Welding Fixtures

3 WH –Chassis and Child Part Welding Fixture

4 WH –Chassis and Child Part Welding Fixtures

The following stages are included in the jigs and fixture design:

- Planning

- Element design

- Layout

- Frame design

EXHAUST WELD LINE

The exhaust welding fixture fitted with silencer offered by us is used for different welding processes in industries. These fixtures are easy to install as well as made with precision and accuracy. These fixtures are highly durable and widely demanded.

We have provided complete welding solution including sequential process – complete Turn Key following Segments Weld Lines.

2 WH-Exhaust Weld Line

3 WH –Exhaust Weld Line

4 WH –Exhaust Weld Line Leak Testing and Pin Marking -SPM