Designing

The first one is designing. The huge technical experience developed over more than 25 years of activity brought our designers to an extremely high level of specialization. Understanding and meeting our customer's needs is our priority in order to contribute to the production process optimization. Optimization means to us verifying if a project can be developed and if proper modifications can be implemented. The production cycle is carried out using the most modern and well equipped fixtures and other technologies. The technical department, with the most powerful CAD systems, developing the project which, once validated comes the tool room in picture which develop all the intricate and precise components involved and are assembled this is where the 3D model is translated into reality.

Development

Our development team is focussed on providing on time support to the R&D sector by developing prototype parts. Our team has successfully developed critical parts which includes:

• Cylinder-head with valve seat and cam-bore machining.

• Cylinder-block with crank-bore machining.

Key components of our development process are:

• Cross functional expertise of engineering concentrations.

• Vast and proven resources.

• Advanced problem solving techniques.

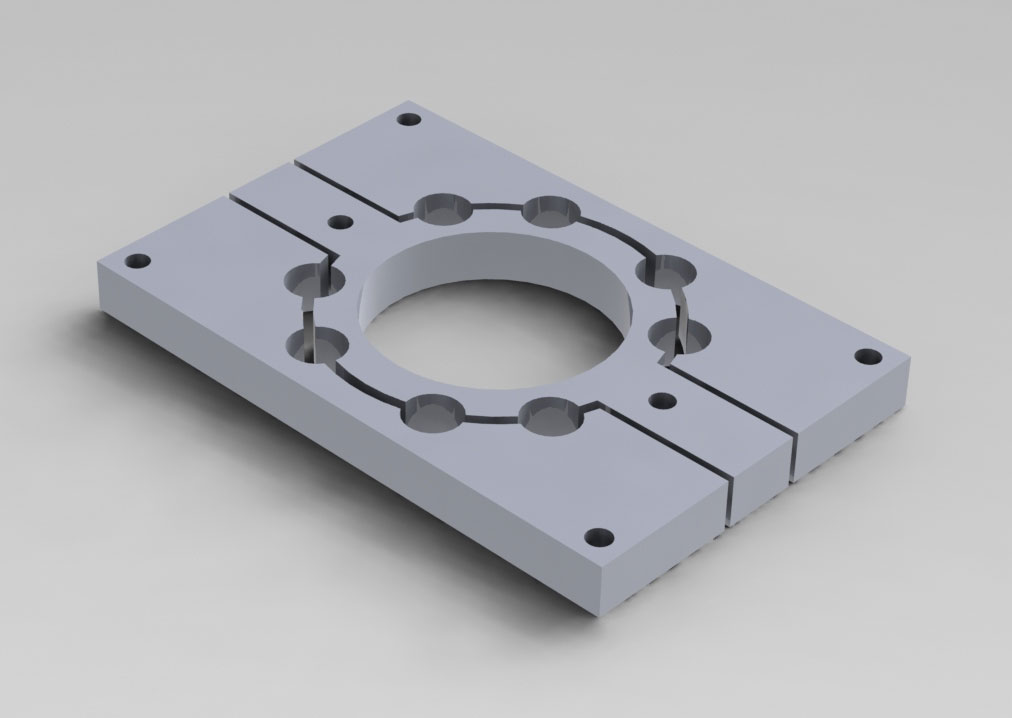

Production

The 3d model is engineered for the CAM processing and available for the machine tools for all manufacturing process. The numerical control machines, all endowed with CAM positions and a tools, get the 3D model while the highly qualified technicians work out the tool path according to the processes to be carried out, thus playing an active role in the decision-making process regarding the tool path setting. A "Product Plan" is drafted for every project. The "Product Plan" defines the list of working steps and establishes the processes to be implemented.

Inspection

Testing grants the accuracy of the 3D model re-production. Through the use of software, machinery testing department acquires the 3D model and compares the dimensions defined in the virtual project with the real ones, highlighting deviations from the tolerances. Compliances tests are effected during the whole production process in order to check every single semi-finished product and grant an appropriate functional layout in the customer's production line. Along with the tooling, the customer is provided with the complete 3D engineering data, the related 2D drawings sets and the dimensional inspection reports. Such documentation is aimed at facilitating all the activities related to product management and especially to maintenance.