Ferrous Metals

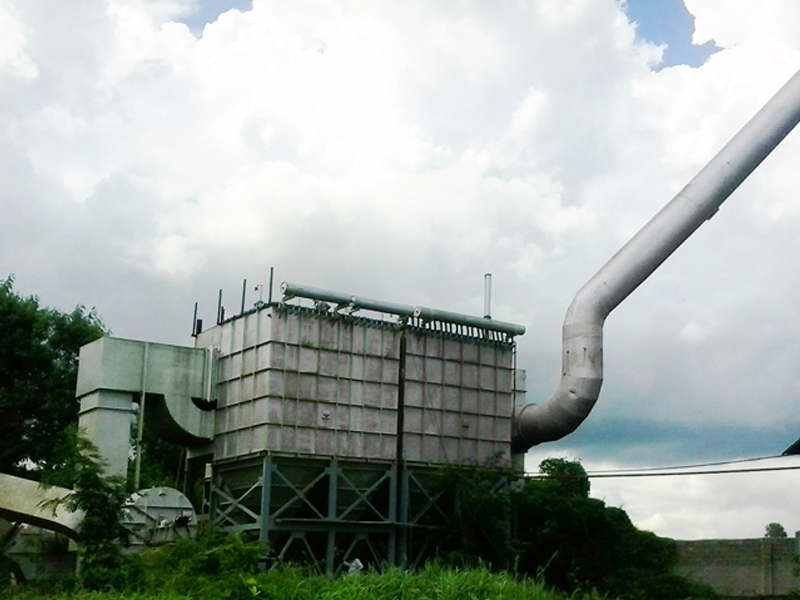

Ecomak offers a wide range of products for Fume/Gas cooling systems, PRIMARY fume extraction system and SECONDARY Fume Extraction System in the following areas for Iron & Steel Industry:

- Induction Furnace (IF)

- Electric Arc Furance (EAF)

- Ladle Refining Furnace (LRF)

- AOD/LD Convertors

- Blast Furnace

- Coking Plants

- Sintering Plants

- Material Handling Plants

- Coal Grinding Plants

- Metal Recovery from Slag

Ecomak is a single-source for audits/surveys, plant design, engineering, production, assembly and commissioning to plant service.

Foundry

Depending on the application requirements, components cast from ferrous or non-ferrous metals are manufactured using a range of processing steps. This creates dust-laden exhaust air, primarily from smelting units (hot and cold blast cupola furnaces, induction furnaces and crucible furnaces). Secondary emission sources are collected during casting in crucible or casting lines, and finally in shakeout stations, casting cleaning rooms and sand plants, as well as during sand cooling and regeneration.

ECOMAK's scope of services covers the entire range of requirements for extraction and dedusting in the following areas:

- Collecting exhaust air

- Cupola furnaces

- Smelting furnaces

- Casting lines

- Shakeout stations

- Sand recovery

- Material Handling Applications

Non-Ferrous Metals

Ecomak provides extraction and dedusting equipment for the non-ferrous metals industry.

Some of the areas in which it is used are as follows:

- Exhaust air collection

- Furnaces

- Converters

- Smelting furnaces

Metal Processing

Ecomak's scope of services cover the entire range required in the metals industry for extraction and dedusting in the following areas:

- Collecting exhaust air

- Hot-dip galvanising baths

- Welding shops

- Sandblasting operations

Sponge Iron

Ecomak has catered to Sponge iron since inception of the company. Ecomak is a single source supplier for all pollution control solutions for the Sponge Iron industry. The sources of pollution where Ecomak caters to in a sponge iron plant are:

- Kilns

- Mills

- Grinding equipment

- Material handling applications

- Other dust sources