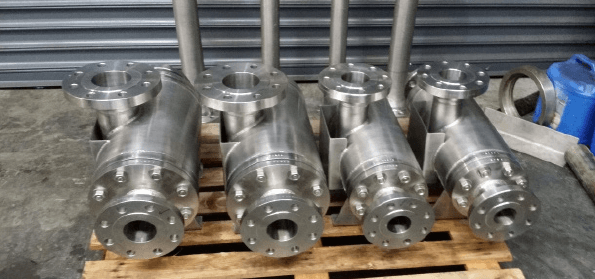

We have the state of art machinary, manpower and facilities for processing custom Stainless Steel Fabrication. Our Laser Cutting, Bending, Welding machinary allows us a best quality, cost efficient and timely completion of work.

Method : Our process chain of Stainless Steel fabrication

- Method : The product is analyzed and the best method of manufactiring is arrived by the design department. The required tooling and ficturing are designed and manufactured. Company has large quantity of flexible fixturing making it possible to make prototypes and first assemblies very quickly.

- Design and Development : Advanced software is used to create 3D models of product. Which are then unfolded to create part drawing . The usage of sophisticated I.T. tools helps in fast preparation of first parts and prototypes. A developed view is then passed on to the programming section, for flat processing. The design of complex bending parts poses a challenge to every designer.

- Programming : NC programs for specific machines are generated from drawing. Two important features of programming are

- The programming system automatically suggest the best and fastest processing method 2. A good programming system always creates a processing definition automatically taking into account the material and the geometric profile . E.g. in the case of a sheet coated with lamination, the programming system must be able to generate an NC code which, at first vaporize the film and then cuts the parts.

- Production : Being with flat sheet processing, blanks are cut from sheet, the parts are then bent, and several such parts are then connected with each other. The individual pieces pass through several stages during the production. The goal to produce the final form is as few steps as possible. At times, machining welding as well as punching/flattening operation, precedes the bending operation.