Flow Elements - Venturi

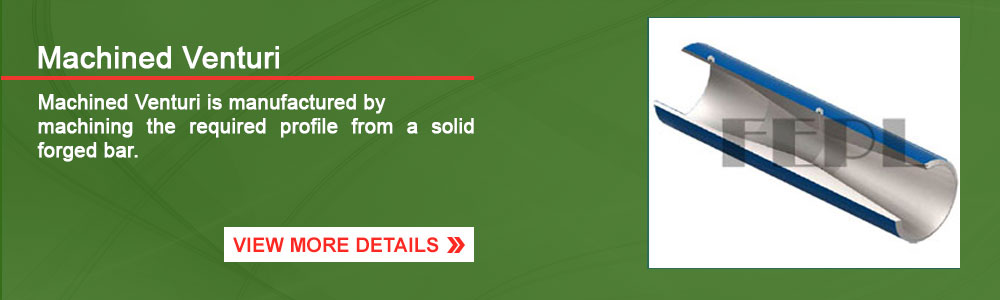

Machined Venturi

Fabricated Venturi

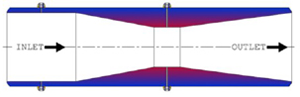

Machined venturi is manufactured by machining the required profile from a solid forged bar. The sizing and dimensional guidelines are mentioned in ISO-5167 part IV. Depending upon the customer requirement, the end connection can be either BWE or Flanged.

Machined venturi is manufactured by machining the required profile from a solid forged bar. The sizing and dimensional guidelines are mentioned in ISO-5167 part IV. Depending upon the customer requirement, the end connection can be either BWE or Flanged.

• Size limits 50 mm to 250 mm.

• Uncertainty in discharge coefficient ± 1%

• ReD 2 x 10^5 to 1 x 10^6

• β 0.4 to 0.75

Materials : The venturi can be supplied in any material including plastics. The materials generally used are SA105, SA182F316/L, SA182F304/L, Inconel, Duplex SS, Monel etc. Venturi upstream pressure tap is located at the mid of inlet cylinder & the downstream pressure tap is located at midpoint of the throat.

When averaging is required, the pressure tapping can be taken through piezometric ring or also called as annular ring. This can be manufactured from forging or can even be fabricated from rolling the pipes, as per requirement.

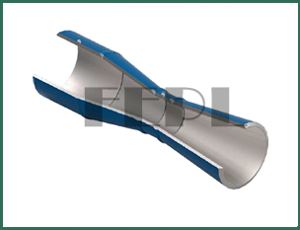

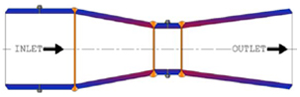

This type of venturi is manufactured by bending the sheets into required profile & joining them together. This type of venturi, is manufactured in different sections named above and then joined together to form a fabricated venturi. Depending upon the customer requirement, the venturi can be supplied in BWE or flanged end connection. For bigger sizes, since the length increases, venturi can be supplied in truncated form.

This type of venturi is manufactured by bending the sheets into required profile & joining them together. This type of venturi, is manufactured in different sections named above and then joined together to form a fabricated venturi. Depending upon the customer requirement, the venturi can be supplied in BWE or flanged end connection. For bigger sizes, since the length increases, venturi can be supplied in truncated form.

• Size limits 250 mm to 1200 mm.

• Uncertainty in discharge coefficient à ± 1.5%

• ReD 2 x 10^5 to 2 x 10^6

• β 0.4 to 0.7

The basic raw material for this type is in the form of plates / sheets. Generally used material grades can be listed as follows :

• Carbon steel IS2062, SA516Gr. 60/70.

• Stainless Steel SA240Gr. 316, SA240Gr. 304, etc.

(Other materials are also available on request). When averaging is required, the pressure tapping can be taken through piezometric ring or also called as annular ring. The ring is fabricated from channel or pipe as per requirement.