Products

- Bullet Dies

- Tungsten Carbide Bushes

- Tungsten Carbide Spl Punches

- Tungsten Carbide Centers

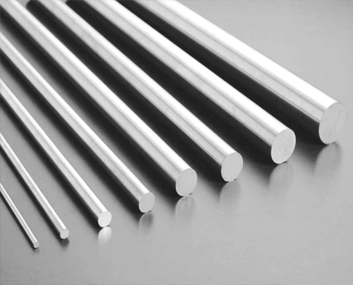

- Tungsten Carbide rods

- Tungsten Carbide Gauges

- Tungsten Carbide Cutting Tools

- Wc_Tungsten Carbide

- Work rest blades

- Ball Nose Cutters

- Special Form Tools & Cutters

Fine Spark

Contact Person

Mr. N.P.Ghodekar

BG/SEI 11/03,

Near BSNL Office, MIDC,

Bhosari, Pune – 411026.

Ph: (020)27129680,

Fax: (020) 27122513,

Mob: 09822043630

E-mail:

finespark@live.com/ finesparkindia@gmail.com

Website: www.finesparkindia.com, www.sme.in/finesparks

About Us

Fine Spark is committed to continuing technological development and implementing exhaustive labor saving measures with the aim of responding more effectively to the demands of its customers in line with its motto of “high quality, low price and rapid delivery.” Moreover, One of the basic principles that the company has held fast to ever since its establishment is to place strong emphasis on personnel training as an essential task. While desk study is certainly important, employees can only master the technology they use through practical hands-on experience. By continuing to adhere to this philosophy in an era in which the processing industry can expect to continue undergoing drastic changes, Fine Spark will strive to broaden the applications of tungsten carbide & steel machining into new fields and achieve further technological progress.

Company Profile:

Company Name: - Fine Spark Status : - Proprietary Factory Address: - BG/SEI 11/03 near BSNL Office, MIDC, Bhosari, PUNE -411026. Telephone/Fax: - (020)27129680/ (020)27122513 Mobile: - 9822043630 Head of organization: - Mr.N.P.Ghodekar 27 year exp. Sandvik Asia Pvt. Ltd. Company Status: - 1995-Present Electric Power: - 30 HP Employees: - 10 People SSI No: - FORM NO.06146 M VAT: - M VAT NO: 27410048562-V-1/4/06 CST NO : 27410048562-C-1/4/06

Area of business engineering

Area of Plant : - 3600 SQ.FEET Covered Area: - 2160 SQ.FEET

Our Infrastructure

We have installed a sophisticated infrastructure, which is equipped with all the facilities required for stable production process. It is partitioned into different sections such as manufacturing, quality control, warehousing & packaging and many more. All these wings are designed in order to carry out their respective tasks within the stipulated time-frame. Our manufacturing unit is the backbone of our firm, which is outfitted with advanced machines and equipment to speed up the production process. Furthermore, the finished machinery components are tested on various parameters, at our quality control unit, in order to ensure delivery of defect-less products to our clients.

Goals and Objectives

*We believe in thorough customer satisfaction by supplying quality products which gives you better output and efficiency. *We train all our employees to improve their efficiency and optimal utilization of resources which affects manufacturing costs and skills of a product. *The product should reach to the customer safely and in stipulated time.

Range of Products:

1. TUNGSTEN CARBIDE PRODUCTS(TC DIES): (DIES for ARMS & AMMUNITION i.e. Bullet Dies & Casing Dies, Cutting & Cupping Dies , Extrusion Dies, Wire Drawing Dies, Tube & Bar Drawing Dies, Cold Heading Dies & Forging Dies, Power Pressing Dies, Fastener Dies, Nib Dies, Draw Dies, Pen Industries Dies, Round Dies, TC RINGS for Sleeves, Forming/Formation Dies & Punch(BLANKS), All Wear Parts, etc…) 2. TUNGSTEN CARBIDE BUSHES: (T.C.BUSH, Drill Jig Bushes, Guide Bushes, Special Bushes, All Wear Parts, etc.) 3. CARBIDE SPECIAL PUNCHES: (Profile Punch, Pressing Punch) 4. CARBIDE CENTERS: (Mt–2 to Mt–6 full & half dead centers) 5. CARBIDE RODS: (Core rods, gauge pin) 6. GAUGES: (Carbide Gauges, Steel Gauges, Checking Gauges, Ring & Snap Gauges) 7. TUNGSTEN CARBIDE CUTTING TOOLS. 8. JOB WORK: (EDM-Sparking on Steel & Carbide, OD & ID Grinding, Wire Cut, Lapping & Polishing of CARBIDE ID, FACE & FORM) 9. All Types OR any Types of Special Items or Jobs are manufactured on request.

About Tungsten Carbide

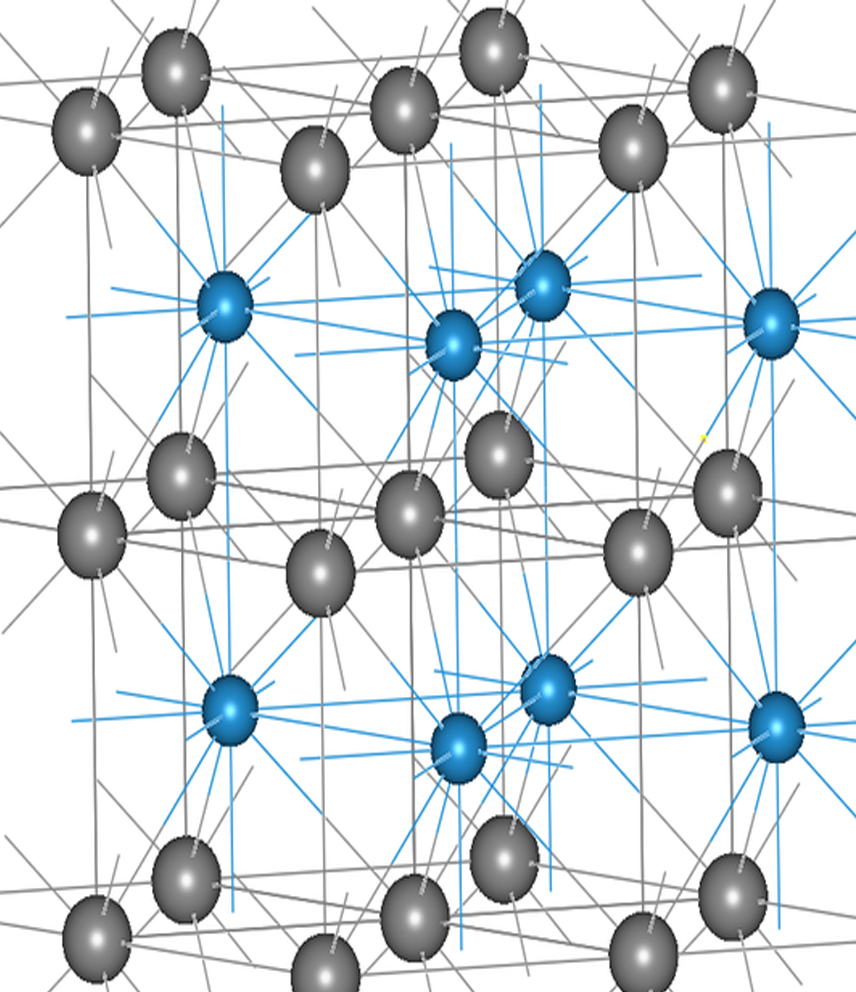

Tungsten Carbide (WC) is one of the most successful composite engineering materials ever produced. Its unique combination of strength, hardness and toughness satisfies the most demanding applications. These characteristics are effectively unrivaled by any other material , which makes it the work-horse as a tool for metal cutting, metal forming , structural components, wear parts and other applications requiring severe abrasion resistance. Wear resistance is the most outstanding feature of tungsten carbide. If the material also has to withstand deformation, impact, heavy load, high pressure, corrosion and high temperature, tungsten carbide is often the only material that can fulfill these requirements satisfactorily. In the years the demand of Tungsten carbide has tremendously increased.

List of Machineries:

1. SPARK EROSION MACHINES (EDM) QTY: 2 2. CYLINDRICAL GRINDING MACHINES (MAKE: STUDER) QTY: 2 3. CYLINDRICAL GRINDING MACHINES (MAKE: NOLAF) QTY: 2 4. SURFACE GRINDING MACHINE (MAKE: SEMCO) QTY: 1 5. PROFILE PROJECTOR: 25 TIMES 6. WIRE CUT MACHINE (MAKE: JAPAX) Qty: 1 7. LAPPING & POLISHING HEADS WITH STANDS: 3 8. ULTRA MODERN INSPECTION SET UP

LIST OF MEASURING INSTRUMENTS:

1. MICROMETER (ALL RANGE & ALL TYPES) 2. VERNIER CALIPER (ALL RANGE & ALL TYPES) 3. GAUGES (ALL RANGE & ALL TYPES) 4. DIAL INDICATORS 5. SURFACE PLATE 6. Etc…