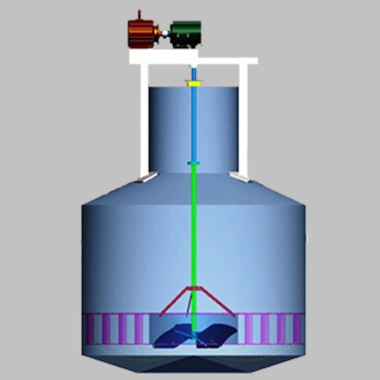

Mechanical Circulator

The circulation of Massecuite within vacuum pans must be as high as practically possible in order to achieve maximum throughput and produce good quality sugar.

The existing Vacuum Pans, with natural convection heat transfer, can be installed with Galaxy Mechanical Circulators.The benefits of having a Mechanical Circulator in your Vacuum Pan are,

ENERGY EFFICIENCY :

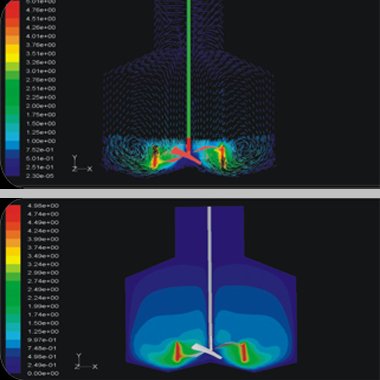

Mechanical Circulator increases the heat transfer co-efficient significantly which leads to lower steam consumption. Avoids head loss in Calendria Tubes and leads to better utilization of Down take diameter.

Capacity:

With increase in heat transfer co-efficient, strike time reduces up to 30%, which in turn increases the Production Capacity

Capacity:

- Uniform Particle Size Distribution

- Uniform Colour of the Sugar Crystal

- Uniform Super saturation Level & Crystal Growth rate across the Pan

- No local or overheating the crystals

RECOVERY:

A higher massecuite dry substance concentration is possible, leading to a higher crystal yield and a lower purity of molasses