Impeller Technology

Selection of type of impeller is at the heart of any mixing process. GEOMETRY of the impeller is of vital importance for any mixer. Impeller characteristics and performances are explicitly linked to the process performance. OPTIMUM PERFORMANCE of mixer relies on utilisation of specific Impeller geometries located at Ideal shaft positions within the mixing vessel.

WE, AT GALAXY INDUSTRIAL EQUIPMENT, recognize the fact that no single impeller geometry is the ideal choice for all Applications and we have to go for combination of differant Implellers to get Optimum Mixing Performance.

IN the quest to offer the Optimum mixing Performance, GALAXY INDUSTRIAL EQUIPMENT has maintained a compresive portfolio of various types of impellers as follows,

Axial Flow Impellers

AXF-32/AXF-22 Narrow Blade Hydrofoil Impeller

The AXF-32/AXF-22 hydrofoil impeller provides a combination of performance characteristics and high flow efficiency not available from other types of axial flow impellers. It can produce the same flow and process results at a lower power than other axial flow impellers thus reducing operating and capital costs.

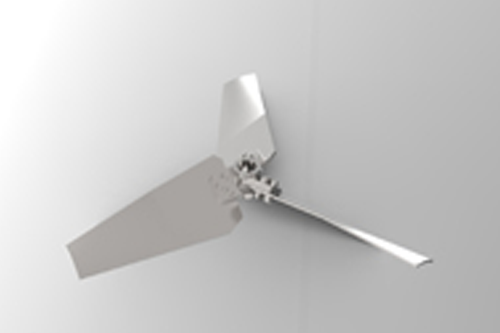

AXF-100/3 MARINE PROPELLERS

The AXF-100/3 series impellers are generic 3 bladed Marine Propellers. These are traditional impellers and are used for variety of flow controlled applications. These Impellers are used in applications where a degree of fluid flow is beneficial to the overall process result.

AXF-320/3 WIDE BLADE HYDROFOIL IMPELLER

High flow impeller for higher viscosity applications.This Impeller is designed to operate in high viscosity fluids (5000 to 30000 cP). The effectiveness of many high efficiency impeller systems which are designed to operate in the turbulent flow regime is impaired as the viscosity of the fluid increases and the Reynolds Number decreases. How-ever, the wide blade hydrofoil impellers can operate in Laminar region as well. Blend times are also reduced compared to other ‘open’ impellers used at low Reynolds numbers.

AXF-315/4 WIDE BLADE HYDROFOIL IMPELLER

AXF-315/4 multifunction impeller used mainly for gas dispersion .high gas dispersion achieve with control flow patterns 25 to 30 % high mass transfer achievement at same torque and power consumption compares to conventional radial flow impellers.

AXF-350/2 HIGH VISCOSITY IMPELLER

AXF-350/2 useful for high viscosity applications. lower power required for full motion blending and heat transfer application in high viscosity and non-nutulian fluids.

AXF-400S SINGLE HELIX IMPELLER

Helix impeller use for high viscosity application that is above 1 lac C.P variable high pitch helix can be design as per process requirement

3 BLADED DRAFT TUBE IMPELLER

This impellers are specifically used for Draft Tube Applications. Because of it’s shape it provides high flow, even in variable process conditions and minimises power requirements.

Mixed Flow Impellers

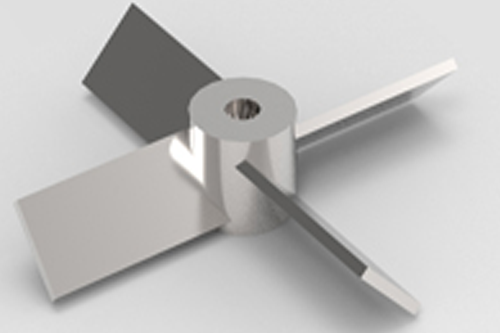

AXF-45/4or6or2 PBT

The AXF-45/4or6or2 series impellers are generic 4 bladed Pitched blade Turbines. These are traditional impellers and are used for variety of applications. These Impellers are used in applications where a degree of fluid shear is beneficial to the overall process result.

AXF-400D DOUBLE HELIX IMPELLER

These Impellers are used where very high viscosities are involved. A variety of options in terms of number of flights, pitch and helix are available to suit the specific requirements of the duty.These impellers promotes good surface renewal and heat transfer.

RXF-400 Impeller

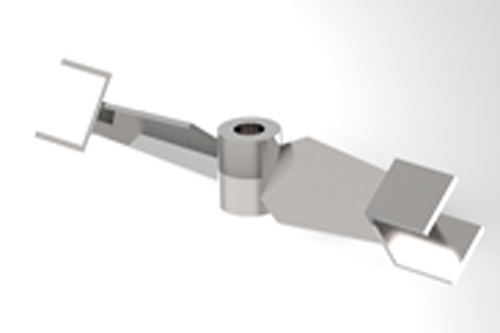

Two bladed anchor for higher viscosity applications.The two bladed anchor impellert has applications in blending and particularly, heat transfer, where the viscosities range from 10000 to 100000 centipoise.

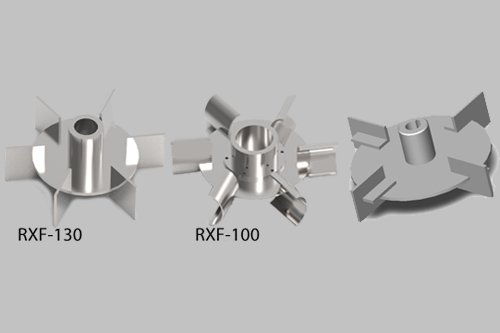

Radial Flow Impellers

The Rushton turbine is the traditional impeller for gas – liquid mass transfer controlled systems. Itis also used where higher shear is needed. The curved blade Rushton Turbine (also known as Smidth Turbine) shown above has similar characteristics to that of Rushton Turbine but gives:

- A higher power input in thegassed condition- Lower power in the ungassed condition

RXF-500 SAW TOOTH IMPELLER

The RXF-500 provides high shear rates. It is generally used in conjunction with a high flow impeller in applications involving a combination of blending and a need for physical change created by fluid shear.These Impellers are used typically for High Shear Applications for dispersing the fine solids.