Email - sge2005@rediffmail.com

Mobile - 8087703223 / 9604682845

Our Products List

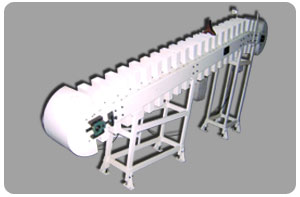

Garud Automation range of hard wearing belt conveyors giving many years of reliability. Our aim is to build a lasting relationship with our clients and offer the complete package.

Can we Help You?

Garud Automation welcomes a challenge and offers our assistance with the development of your

production processes.

Each of our conveyors is engineered to handle your products carefully.

Materials used to fabricate the frame are usually dictated by your industry

we offer stainless steel, mild steel and aluminum; Belting is also variable and includes;

• PVC Polyurethane Silicon

• Resin

• PU Belt

• Teflon

• Plastic Belt / Modular Belt

• Felt Rubber

• Wire Belt

Industries we supply to include.

• Logistics & Transport

• Building & Construction

• Industrial Applications

• Flat Belt Conveyors

Conveyor Belts how versatile are they?

• Belt sizes start at approximately 100mm up to 1000mm as standard but we can offer much wider

belts for special applications.

• Side Guides can be added to restrict your products if desired.

• Elevating your materials on inclines or declines is achieved by fixing flights to the belt.

• The number of flights and what pitch will be dictated by the angle desired and your product.

• Speed can be varied by adding an inverter of mechanical variator and typically can run 2m/min to 50m/min defendant on product.

• For convenience of transporting your belt conveyor it can be made portable by adding casters

when the legs are being fabricated.

• We are able to supply belt conveyors that will accommodate bends and corners.

• Bespoke Systems designed to carry tubes.

• Modular Belt Conveyor transporting packs of rice using plastic belt and gravity rollers.

• Magnetic Conveyor used to convey empty cans for a food factory into the processing areas for

filling and packing.

• New product our Close Transfer Conveyor.

• Tube Sorting Conveyor System.

• Side Grip Belt Conveyor which is fully adjustable to suit different size products.

• Sortation Twin Lane Conveyor.

• Trial system set up for a company to try their products on one of our Inclined Belt Conveyor.

• Plastic Modular Belt Conveying loose and packed wet wipes.

Roller Conveyors :

The most economical and straightforward method of transporting loads.

Moving products with little or no effort and relies on gravity with a slight decline or manually rolling the product along the rollers; best suited to a flat based product.

Gravity Roller System fabricated in mild steel

Light Duty Garud Automation Roller Conveyors

Offering 3 grades of Light Duty Gravity Rollers :

• Products up to a maximum weight of 10kg - 40mm Dia grey rigid PVC Roller

• Products up to a maximum weight of 15kg - 50mm Dia grey rigid PVC Roller

• Products up to a maximum weight of 20kg - 35mm Dia Steel Roller

Medium Duty Garud Automation Rollers Conveyors

Offering 2 grades of Medium Duty Gravity Rollers :

• Products up to a maximum weight of 30kg - 50mm Dia Steel Roller

• Products up to a maximum weight of 40kg - 50mm Dia Steel Roller

Heavy Duty Garud Automation Gravity Rollers Conveyors

We can supply 2 grades of Heavy Duty Gravity Rollers :

• Products up to a weight of 750kg - 50mm Dia Steel Roller

• Products up to a weight of 1500kg - 60mm Dia Steel Roller

Ball Table Photo for Conveyors

Ball Table Photo for Conveyors

• Bulk Material Handling Solutions at Low Costs.

• Providing cutting edge solutions for bulk handling for all industries.

• If its achievable Garud Automation will find the solution best suited to your products or waste.

We offer wide range of Gravity Roller Conveyors which is used for delivering cost effective and virtually maintenance-free handling of goods in various industrial applications.

We offer wide range of Gravity Roller Conveyors which is used for delivering cost effective and virtually maintenance-free handling of goods in various industrial applications. Type of Chain Conveyor :

• Accumulator Chain Conveyors

• Accumulator Chain Conveyors

• Extended Pitch Chain Conveyors

• Powered Chain Roller Conveyors

• K2 Chain Conveyors

A chain conveyor is a type of conveyor system for moving material through production lines.

Chain conveyors utilize a powered continuous chain arrangement, carrying a series of single pendants The chain arrangement is driven by a motor, and the material suspended on the pendants are conveyed Chain conveyors are used for moving products down an assembly line and/or around a manufacturing or warehousing facility.

Chain conveyors are primarily used to transport heavy unit loads, e.g. pallets, grid boxes, and industrial containers These conveyors can be single or double chain strand in configuration The load is positioned on the chains, the friction pulls the load forward

• Chain conveyors are generally easy to install and have very minimum maintenance for users.

• Many industry sectors use chain conveyor technology in their production lines.

• The automotive industry commonly uses chain conveyor systems to convey car parts through paint plants.

• Chain conveyors also have widespread use in the white and brown goods, metal finishing and distribution industries.

• Chain conveyors are also used in the painting and coating industry, this allows for easier paint application.

• The products are attached to an above head chain conveyor, keeping products off of the floor allows for higher productivity levels.

Slat Conveyors in Stainless Steel & Plastic

Applications :

• Slat Conveyors are used when rapid speed and accuracy is essential.

• Stainless Steel options are often found in Food, Pharmaceutical, Processing & Packaging Industries.

• However Mild Steel versions can equally transport heavy duty products.

Benefits :

• Supplied complete with a full product warrantee for parts and labour.

• Fabricated in Stainless Steel and mounted on a S/S framework making Garud Automation.

• Slat Band Conveyors extremely hygienic enabling a complete wash down facility.

Specification :

• Slats options include manufactured in heat resistant plastic (Acetal ) or Stainless Steel allowing them to be used for heat drying process applications giving long lasting dependable performance.

• Supplied in fixed or variable speed drives with or without side guides.

• Usually mounted on tripod style legs which can have an adjustable height facility.

• Low friction of Slats make ideal systems for lablelling and packaging industry.

Frequently Asked Questions :

1. Am I able to use a slat conveyor with food products?

That is not a problem most of our slats are supplied to the food industry. The frame would need to be fabricated in Stainless Steel at a food grade quality.

2. I need a conveyor to go around a bend are slat conveyors able to do this?

Yes Slat Conveyors are able to go round corners rule of thumb is a chain can be turned round a center line of 610mm.

3. Is tracking necessary with a slat conveyor?

This type of conveyor does not need to be tracked.

4. Is it possible to go round a bend and an incline at the same time with a slat conveyor?

Flights can not be fitted to a radiuses chain but it is possible to fit rubber inserts that will elevate your product.

5. What size do you provide your slats in?

We have a standard range is 3.25" wide and increases up to 12" wide. However other sizes can be provide please call us with your requirements.

6. Is it possible to remove a link and how easy is it to do?

It is extremely easy to replace a link by pushing a pin through the chain hinge. It can be done in seconds.

7. What speed can a slat conveyor run at?

This will depend on the product that is being handled. but generally 1metre per min up to 50 meters per min. This can be varied for extreme special uses.

8. Would accumulation be possible on a slat conveyor?

The type of slat selected for your product is vital to achieve this. The materials can vary from low friction to extremely high grip. Please make sure you are advised by someone with this knowledge.

9. Is the speed of a slat conveyor variable?

This can be achieved by adding an VFD or a mechanical variator.

10. Is it possible to get close transfer with a slat conveyor?

This is done by using a side transfer with a 3mm gap.

11. Can a slat conveyor be used with flights to raise by my product up an incline?

This is not really the best type of conveyor for a incline please refer to our modular belt conveyors. A slight incline is achievable with no flights.

12. How easy is it to replace a slat chain?

Very easy it can be replaced in minutes.

13. Can raw food be placed on the slats?

Slats are available in stainless steel and plastic so yes it is possible to transport raw products on our slat conveyors.

14. I think my slat chain has stretched is that possible?

Yes once bedded in the slats will have stretched remove a link to eliminate this.

15. How expensive are slat conveyors?

They are a little more expensive than a traditional belt conveyor but will last longer they are also easy to clean and there are no tracking issues, and of course you do not have to replace all at once links can be replaced one at a time.

We are offering a comprehensive range of Conveyors that forms an adequate material handling solution at work.

These are manufactured using high grade raw material and are acknowledged for precise functioning and durability. Available in different designs and sizes, their usage expedites the transfer process and eliminates excessive labor.

Moreover, we also offer customization facility to our clients.

We meet the requirements of clients by offering varied range of conveyors :

| Assembly Line Conveyors | Auto Loading Conveyors |

| Belt Conveyors | Bottle Conveyors |

| Bucket Conveyors | Bucket Conveyors |

| Chain Belt Conveyors | Chain Conveyors |

| Chain Driven Conveyors | Conveyor Systems |

| Conveyors Idlers/Rollers | Conveyors Systems |

| Driven Roller Conveyors | Feeding Conveyors |

| Flat Top Conveyors | Gravity Conveyors |

| Gravity Roller Conveyor | Idler Roller Conveyors |

| Inclined Conveyors | Loading Conveyors |

| Packing Conveyors | Pallet Conveyors |

| Pneumatic Conveying Systems | Portable Conveyors |

| Powered Roller Conveyors | Roller Conveyors |

| Rubber Belt Conveyors | Slat Belt Conveyors |

| Slat Conveyors | Accumulating Chain Conveyors |

This is useful for Automatic & Auto Industry, Precision Engg.

Industry, Food industry, Beverages & Soft Drink Industry, Medical, Pharmaceutical, Cosmetic, Electric Industry etc.

Also avilable in sizes redius, stright & 90 degree. As per customer requirement.

This is useful in heavy & light Industry. This is free tyoe conveyor to avide metal to metal contact.

Pu Roller Conveyor to use both side bearing for smooth working.

Width & sizes is depend on customer requirment.

We are offering a wide range of Special Purpose Machines (SPMs) that is highly appreciated by our clients for attributes such as abrasion resistance, longer service life and precise functioning.

These are manufactured using high grade raw material and advanced technology in order to ensure efficient work output that sufficiently cater to the requirements of varied industries. Our complete range is dimensionally accurate and delivers superior performance. Moreover, we also customize these machines as per the specifications laid down by our clients.

CNC Controlled Special Purpose Machines |

CNC Controlled SPM |

Hydraulic Machines (Special Purpose M/c) |

Indexing Machines for Product Assembly |

PLC Controlled Special Purpose Machines |

PLC Controlled SPM |

Pneumatic Machines (special Purpose M/c) |

Special Purpose Automations |

Special Purpose Machines in Coolants |

Special Purpose Machines In Pressure |

Special Purpose Machines in Vacuum |

Degassing Units for Aluminum Foundry |

Aluminum Recovery Units from Sludge |

Vacuum Sample Testing Units |

Forced Cooling Systems for Aluminum Cast |

|

A Programmable Logic Controller ( PLC ) is a digital computer used for automation of industrial processes, such as control of machinery on factory assembly lines. Unlike general-purpose computers, the PLC is designed for multiple input and outputs, extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact. Programs to control machine operation are typically stored in non-volatile memory.

A Programmable Logic Controller ( PLC ) is a digital computer used for automation of industrial processes, such as control of machinery on factory assembly lines. Unlike general-purpose computers, the PLC is designed for multiple input and outputs, extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact. Programs to control machine operation are typically stored in non-volatile memory.

PLCs are armored for severe condition (dust, moisture, heat, cold, etc) and have the facility for extensive input/output (I/O) arrangements. Functionality includes sequential relay control, motion control, process control, distributed control systems and networking.

We offer Pneumatic Lifter which are stringently checked by our quality checkers on various parameters and then are delivered within a stipulated time frame.

We offer Pneumatic Lifter which are stringently checked by our quality checkers on various parameters and then are delivered within a stipulated time frame.

Further, our range of Pneumatic Lifter is well known for their efficiency and reliability and is widely used in various industries.

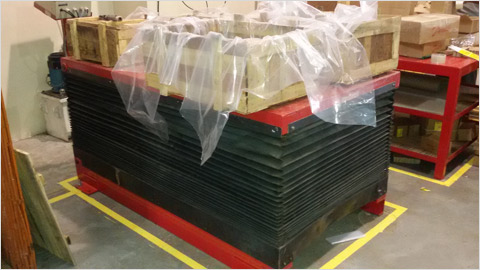

We offer high quality Scissor Lifts that is developed using finest quality inputs. Our gamut is hydraulically operated by using latest hydraulic technology. These are available in various forms like single, double or multi stage Scissor Lifts.

We offer high quality Scissor Lifts that is developed using finest quality inputs. Our gamut is hydraulically operated by using latest hydraulic technology. These are available in various forms like single, double or multi stage Scissor Lifts.

Our Scissor Lifts exhibit following salient attributes:

• High pay load capacity up-to 1200kg.

• Robust structure.

• Low closing height feasibility up-to 200mm.

• Cartridge type manifold assembly.(optional).

• Easy for the maintenance.

• Guided roller.

• Sudden fall safety through hose burst valve.

• Low operating pressures.

Applications Area:

• Automobile industry

• Pharmaceutical industry

• Garage application

• Maintenance application (Mobile)