About Us

Proximity Switches

- What is proximity switch?

- What is the sensing zone?

- What is sensing distance?

- What is Repeat Accuracy?

- What is Response time?

- What is Flush Mounting?

- What is Non-Flush mounting?

- What is Switching Hysteresis?

- What is Output Logic?

- What is Load Current?

- What is NAMUR sensor?

- .What is Switch with Built in timer?

- What is correction Factor?

- What is inductive proximity switch?

- What is an Optical Proximity Switch?

- What are Gear Tooth sensors?

- What is an Ultrasonic sensor?

- What is probe size?

- What is end termination?

- What is proximity switch?

Proximity Switch is non-contact type limit switch. with variety of outputs, Ex. Linear, digital, etc.

TopThe switch has a dome shaped field present in front of the sensor is called as sensing zone.

TopThis is the distance between the target & the sensing face at which the switch operates. ( ex. This is usually specified considering MS material as target in case of inductive proximity switch.)

TopThis is the accuracy whereby the switch operates repeatedly at specified point of operation given stable operating conditions.

TopThis is time by which the switch changes its state after target enter the sensing zone. For DC switches the response time can be as low as 0.1 ms but for AC switches this is around 20 ms due to external load parameters.

TopIf switches referred to as Flush type can be mounted inside metal body and have only frontal electromagnetic field.

TopThese type of switch has been mounted with sensing zone in metal free area.

TopThis is the differential between "switch ON "and "switch OFF" point of the switch. Which helps avoiding chattering at the sensing point.

TopThe output switching element (either a Transistor or Thyristor) can be normally in closed (ON) OR open (OFF) condition. It can sink , or source , examples as below, PNP-NO , NPN-PO, ETC.

TopThis is max. Current, which the switch can either sink from or source to the external load.

TopThe NAMUR type sensor is intrinsically safe proximity switches designed to work in the hazardous areas. The working voltage & current levels of these switches are restricted to safe values as per standards.

TopThe NAMUR type sensor is intrinsically safe proximity switches designed to work in the hazardous areas. The working voltage & current levels of these switches are restricted to safe values as per standards.

TopTargets other than MS actuate the inductive switches at relatively less distance with correction factor.

TopInductive proximity switch works on principle of Damping of oscillations by conductive materials. Senses only metallic objects It is useful for medium counting speed. It has short sensing gaps.

TopOptical proximity switch works on principle of interruption / reflection of infra red beam light. Senses any opaque object from longer Sensing Distances with Medium counting speeds and high position sensing accuracy.

TopGear tooth sensors are used to sense the small M.S. gear teeth rotating with high speeds. Its operating frequency is as high as 10 K Hz.

TopUltrasonic sensor works on principle of High Frequency ultra-Sound Wave Propagation. It has very log sensing. Ex.distances up to 20 mtrs.

TopIt gives the shape and dimensional detail with mounting arrangement of the proximity switch.

TopIt is a provision to connect the switch with external load. Normally it is 2 or 3 or 4 core cable. Some time a detachable connector is used.

Electronic Speed Switches

1.What is Electronic Speed Switch ?2.What is it's necessity & where it can be used ?

3.How this switch is superior than the (Contact type) others ?

4.Principal of Operation?

5.How this switch is Practically operated?

6.Construction of Speed Switch

7.What is the function of monitoring unit ?

8.What are the monitoring style of monitoring unit ?

9.What are the different displays provided on monitoring unit and different setting knobs.

10.Analog & digital displays.

11.What are the different facilities provided on the front panel of monitoring unit.

12.What are the different enclosure material for monitoring unit ?

13.What are the Different Protection grades of Electronic speed switch ?

14.How external connections can be done with this switch.

15.Dimensions of enclosure

16.What is a sensing probe ?

17.Working of sensing probe

18.Sensing distance (effective)

19.What are the different sizes & shapes available & can be provided ?

20.Mounting style of probe

21.Inrerconnection betn monitoring unit & sensing probe.

22.Specifications provided on the probe

23.Enclosure provided for the probe

24.What is flag. What is reletion between speed (in rpm) & No.of flags?

25.Genaral specifications of the switch.

26.What are the operational features

27. There is no maintainable is required for this switch as there is no moving parts inside also there is no making or breaking of contact (heavy) hence there is no need of servicing.

28.What are the different types of the switch ?

29.What are the application of speed switch ?

30.Flush & projection mounting of probe

31.Output contact provided

1.What is Electronic Speed Switch ?

The Electronic Speed Switch is a switch who sense the speed of rotating part & monitor (shows) any change in speed within certain speed range which already decided. And thus we can have a control over whole system where this switch is installed.

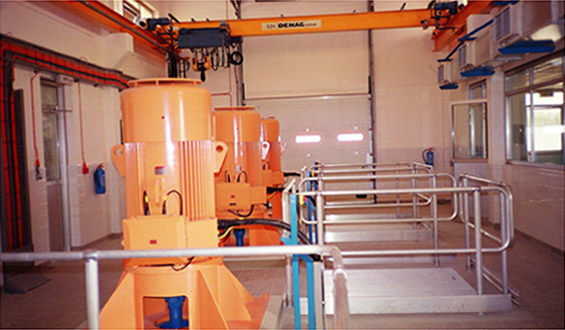

Top 2.What is it's necessity & where it can be used ?To overcome the damages due to variation in speed. Some time due to this (variation in speed) the quality or dimensions can be differ from the standard one. Big breakdown may occurs, motor get damaged, the operator of the system may get injury. To avoid all these things we have to use the speed switch. We can use this arrangement at variety of industrial drives in material handling & processing industries, such as conveyors, crusher, Agitators, Bucket elevator, fans, Drive chains and similar rotating machinery. By adding some developments we can use this switch with other many systems.

Top 3.How this switch is superior than the (Contact type) others ?The sensing probe of this switch is non-contact type either inductive (or capacitive) i. e. actually without touching the rotating part of the machine this can sense the speed and the speed of rotating part which can rotates in either directions. Also as there is no rotating part & mechanical part in probe there is no maintenance probe and it can be use anywhere in industry, as its IP 67 no need of perfect align the sensed signal can transmit at any long dist. (500 Mtr.)

Top 4.Principal of Operation?When a metallic body (here flag) cuts the magnetic field (Here due to sensing probe electromagnet) which is radiated by the probe is get damped giving corresponding output pulses. These are then goes to monitoring unit & the further action takes place.

Top 5.How this switch is Practically operated?Speed or motion of the rotating machine is sensed by the non-contact inductive type sensing probe. The probe is installed with its sensing face in close vicinity of the rotating part (flags) at suitable place. Metallic places of suitable dimensions are to be mounted on the rotating part. When flag passes across the face of probe, frontally radiated electromagnetic field of the probe is get clamped giving rise to corresponding o/p pulses. These pulses are then led the monitoring unit via inter connecting cables. The sensing probe can be mounted at the maximum distance of 500 meter from the monitoring unit. A LED located at rear side indicates the visual indication of sensing of flag.

Top 6.Construction of Speed SwitchThis switch consists of two main parts as monitoring unit & sensing probe. Monitoring unit consist of the control circuit & sensing probe. Monitoring unit consist of the control circuit & sensing probe consist of the sensing unit which sense the speed of rotating part of machine.

Top 7.What is the function of monitoring unit ?The monitoring unit consists of the digital circulatory to give the response to signal received by sensing probe. This unit is provided with the setting knobs for step less setting of speed/bypass time. It also carries LEDs and 7 segment display to show the supply & relay status. Suitable terminals to accept up to 2.5 mm sq. cables are provided. This unit is available in variety of enclosure which are suitable for projection or flush mounting. Also different protection grades can be provided. On the name plate (or on front panel) all general specifications are provided.

Top 8.What are the monitoring style of monitoring unit ?This can be mounted with both projection & flush style of mounting. Also the whole unit monitoring & sensing probe both are available in tabular from with flush type of mounting.

Top 9.What are the different displays provided on monitoring unit and different setting knobs.These are LEDs provided on the unit which shows the supply & relay states, similarly digital displays are also available where we can see the preset time & speed range & for setting the time (TD, NTD, NITD etc) & speed a step less knob is provided on dial marking is provided which shows the position of the knob.

Top 10.Analog & digital displays.

Analog i. e. LEDs are provided to show supply & relay status & the knobs position shows the selected time delay & speed limit while when there is digital display we can see all setting on display directly by pressing a switch.

Top 11.What are the different facilities provided on the front panel of monitoring unit.Here the type of switch & its different ratting are provided also the setting knobs with step less & smooth working to set the time & speed. Supply & relay status also indicated by different colored LEDs for external connectors at terminal there we stick a diagram.

Top 12.What are the different enclosure material for monitoring unit ?For this purpose we have plastic / sheet metal, Robust cast Aluminum, CA materials are available to fulfill the conditions of different protection grades, with other material we may not get these much standard result. Also the properties of these material are good.

Top 13.What are the Different Protection grades of Electronic speed switch ?We provide following protection grade

IP 30:- In this protection grade we have to protect our equipment (switch) against contact with live or moving parts inside the enclosure by tools, wires or such objects thickness greater than 2.5 mm.

IP 55:- In this protection grade we protect switch against harmful deposits of dust. The ingress of dust is not totally prevented but dust can not enter in an amount sufficient OK to interfere with satisfactory operation of the equipment enclosed. And also water projected by a nozzle from any direction under started conditions shall have no harmful effect.

IP 65:- In this protection grade we provide complete protection grade against contact with live or moving parts inside the enclosure. Protection against ingress of dust. And also protection against water jets under stated conditions. Also there is a flameproof protection grade which can withstand up to high temp. And this grade has CMRS certificate (Central Mining Research Station)

Relevent IS No. These above protection grade are from IS : 2147, & = by

INDIAN STANDARD ITSTITUTION. Top 14.How external connections can be done with this switch.For the external connection we have provided the switch with different terminals as IP 00 mouled block, Elmex CST 4, specialstud type. The maximum voltage & current carring capacity (ratting) of the terminals can be varied according to external equipment (system) or to fulfill the protection grades conditions.

Top 15.Dimensions of enclosureThis can be seen in the diagram Provided.

Top 16.What is a sensing probe ?

It is a just like eye of the switch which sense the speed (see) of rotational motion system & gives the corresponding o/p signal.

Top 17.Working of sensing probeWhen this probe is provided with the proper signal (supply voltage)it starts working it radiat the electromagnetic field in front of it's face (sensing) & when this radiateel field cut by metallic body (flag) it gives rise to corresponding output pulse which further goes to monitoring unit i.e. in short it working is to sense the speed/motion of the rotating machine. Protection grade for sensing probe — IP-67

Top 18.Sensing distance (effective)We stated just above that it sence the speed,but for sensing speed this probe should keep within sensing distance which is different for different sizes. Diagram (Normal & Effective sensing distance)

Top 19.What are the different sizes & shapes available & can be provided ?These are available in tabular threaded metallic shapes & sizes can be change but the standard probe is M-30 type. And on request other standard sizes can be provided.

Top 20.Mounting style of probeSame as monitoring unit projection or flush mounting style is available but here other style of mounting can provided.

Top 21.Inrerconnection betn monitoring unit & sensing probe.The signal created by sensing probe w.r.t.speed of machine is transmitted to Monitoring unit via a cable which should be a separate 3 core armoured/shielded Type at least 0.559 mm.Other cables can be provided (as taflon). The Maximum dist. between monitoring unit & sensing probe is about 500 mtrs.

Top 22.Specifications provided on the probeIt's sensing distance,supply voltage,type,current voltage ratings etc.

Top 23.Enclosure provided for the probeThe probe is enclosed in a metallic/plastic enclosure with tubular threaded type. A Special cast Aluminium protective enclosure can be provided on request. Probes in Plastic block.

Top 24.What is flag. What is reletion between speed (in rpm) & No.of flags?To sense the speed to probe the electromagnetic field radiateel by probe should be Interrupted by metallic body (electrically concluctive) & this body is known as a Flag. The minimum & maximum size of flag is shown on the drawing sheet.

Range (RPM) 1-10 5-50,10-100 50-500,100-1000 500-5000 No.of flags 8 4 2 1 Top 25.Genaral specifications of the switch.Supply voltage- 24V/110V/240V ±15% AC/DC Power consumption — 5 VA max. Speed ranges- These are six as, 1-10/10-100/100-1000/5-50/50-500/500-5000 speed setting accuracy with ±5% Actuation differential — Less than 5% of set value Visual indication — Red LED for supply ON Green LED for relay ON O/P contact ratting — 6A resistive at 240 VAC Ambient temp. — 60 Deg. C max. No. of flags — As per described.

Top 26.What are the operational featuresTD:— Built in initial bypass time delay NTD:— Built in nuisance tripping delay NITD:—Combined nuisance + initial delay AD, DD:—An log, digital display (respectively) S:—Selector switch with multi range unit

Top27.There is no maintainable is required for this switch as there is no moving parts inside also there is no making or breaking of contact (heavy) hence there is no need of servicing.

Top 28.What are the different types of the switch ?The basic types of switches — RM 2210:—Unit with only display

RM 2211:—Under speed monitor

RM 2212:—Over speed monitor

RM 2213:—Combined over + under speed

RM 2214:—Under speed monitor with probe to sense speed of belt directly

RM 2215:—Under speed with relay operation for sequential starting of belt.

RM 2216:—Slip monitor

For sensing the speed of the conveyor we have to use the switch RM 2214.Similarly we can use switch at different places with slightly modifications.

Top 30.Flush & projection mounting of probeIn projection type of mounting of probe the electromagnetic field has the spread area around the plastic cap as shown & in flush mounting as the plastic cap is covered by the enclosure material we will not get the spread electromagnetic field as shown. And hence we will get more sensing distance with projection type of at mounting while with flush we won't

Top 31.Output contact providedThere are two types of it as 1 NO + 1 NC & 2 NO+ 2 NC with required ratings. These contacts ( i.e. terminals) are of 6 A resistive at 240 VAC. As in many cases these terminals are connected to the starter of the motor at

Top

Jayashree Electrodevices |

|

|

|

| Conveyor Safety |  |

| Conveyor Safety |  |

| Servo Drive |  |

Jayashree Electron |

|

|

|

| Sensor Solutions |  |

| Digital Soft Starters |  |

Jayashree Encoders |

|

|

|

| Heavy Duty Encoders |  |

| Solid Shaft Encoders |  |