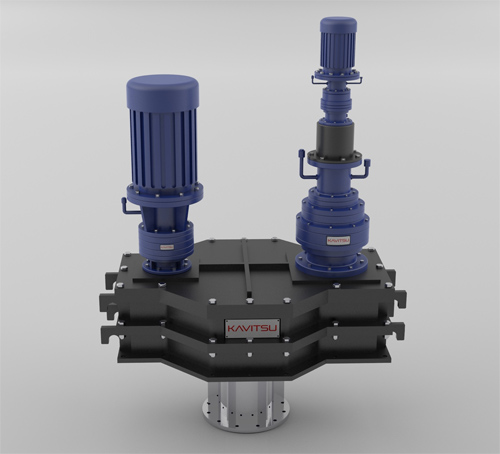

Clarifier Gearbox

They say, water is precious. But looking at the current scenario, it is essential to save every drop of water, or better, re-utilize it. Industries have to pay heavy amounts of money if they are to take the water from lakes and rivers. But, if they have the facilities to re-treat the used water, it helps them conserve the natural resources as well as their costs. The equipment where the waste water or sewage is treated is called a clarifier. Planetary gear system is one of the advanced technologies available for industrial power transmission as of today. Major advantage is their compactness as compared to the conventional systems when it comes to usage in a Clarifier.

Kavitsu has been supplying gear drives for Clarifier in waste water treatment and sewage water treatment plants since 2 decades. Having already pioneered the planetary gear technology, using a combination of planetary and helical, Kavitsu is able to provide uni-axis twin output gearbox to be used in the treatment plants. These gearboxes are generally used for clarifiers, where two outputs, each having different rpm’s are required.

The video above shows the working of the clarifier gearbox. The outer RPM is approximately 20 RPM whereas the inner RPM which is generally a High Torque, Low Speed is around 3 RPH.

Depending on the size of the tank, the suitable selection of gearbox is made. In case of a tank diameter less than 3m, we suggest the use of single agitator type gearbox. If the tank size is between 3m to 17m, we suggest twin output uniaxis gearboxes. Our latest development, an integrated solution for tank sizes >17m, a combination of planetary gearboxes as well as slew bearings is used to achieve the required torque and speed. Some of the advantages can be noted below :

- They have high power density.

- Due to the higher power density as compared to conventional systems, they are compact.

- They are highly efficient when it comes to power transmission. Around 95% efficiency can be achieved using these type of gear drives.

- They provide greater stability.

- Load is distributed evenly among the planetary gears.