About Us

We are a composite engineering set up with integrated manufacturing facilities for below mentioned products. Our group is based in Mumbai with distribution network spread PAN India. In addition to global exports. We are 9001: 2008 certified organization having footprints in sectors including Power, Oil & Gas Energy, Telecommunications, Electrification, Construction, Industrial Infrastructure, Rural, Shipping Sectors, etc. We are enlisted and have contributed to various projects in Govt, Semi Govt, and corporate companies. We have also provided services to major consultants pan India . Our vision is to become a major supplier of galvanized steel in all applicable sectors using un-protected steel prone to faster corrosion.

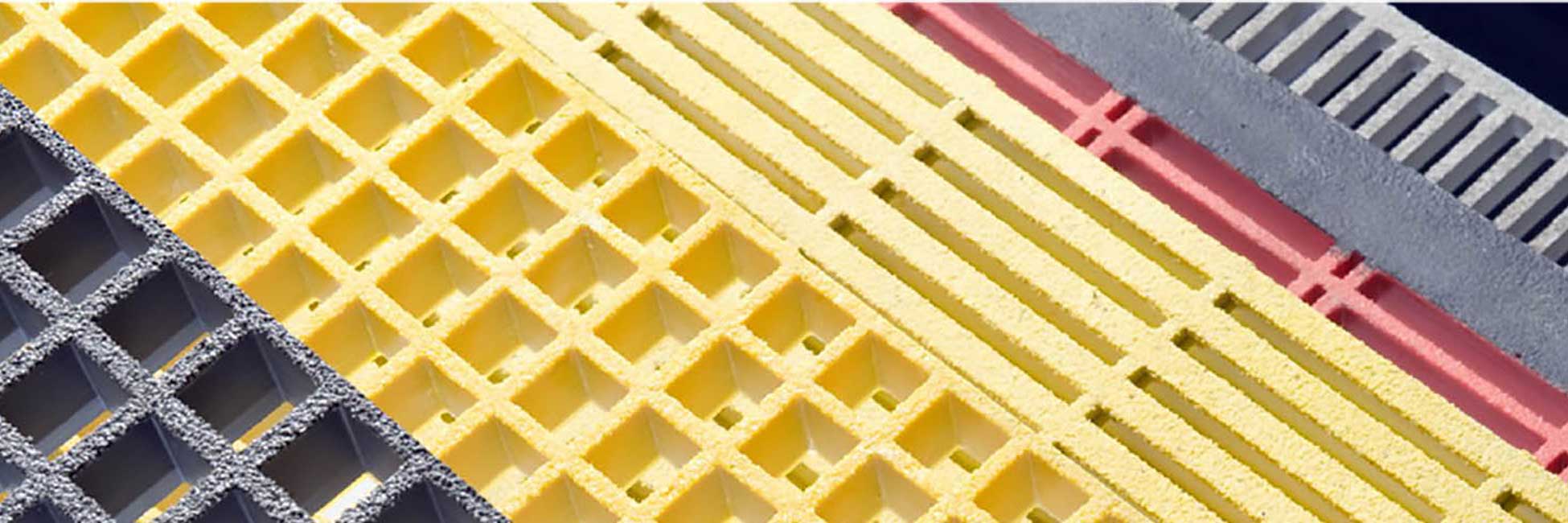

Pentax Ferro Inc, is a manufacturer of Industrial floorings (Gratings), Sheet metal solution provider & General fabricator having integrated manufacturing facilities for Grating (Industrial Floorings) & cable trays, Cable support Systems & other sheet metal components at Wada, District Thane, Maharashtra, India. Further we have a design wing dedicated to providing sustainable sheet metal solutions finding application in multiple sectors.

We are an ISO 9001-2008 company with established infrastructure coupled with competent Manpower having sustainable footprints in wide gamut of industries including infrastructure, oil & Gas, Energy, Chemicals, Mining, Industrial, Ship building, Hospitality, Construction, etc.

| No. | Particulars | Certification |

|---|---|---|

| 1 | Hot Dip Galvanizing (Sundry) | ISO 9001-2008 |

| 2 | GBARZ (Galvanized Re-Bars) | BIS Approved |

| 3 | Sheet Metal Division a) Cable Trays b) Cable Support System c) Solar Mounting Structure | ISO 9001-2008 |

| 4 | Gratings and Trench Cover Division | ISO 9001-2008 |

| 5 | Transmission Towers & Substation Structures | ISO 9001-2008 |

| 6 | Earthing Materials | ISO 9001-2008 |

| 7 | General Fabrication & Galvanized products as per client specification | - |

OBJECTIVE

To remove the responsibility for quality from the hands of the individual and encourage greater awareness of quality in everyone directly or indirectly through integrated systems. This inculcates and enhances our objective of job satisfaction, a safe working environment and harmonious prosperity in national interest.

QUALITY POLICY

We are committed to total customer satisfaction through our practice of providing Quality in compliance to the standards by :-

– Delivering defect free product on time, every time.

– Training motivating and involving all employees to achieve continual improvement in all areas of operations.

Target for quality objective are decided at the beginning of every financial year and reviewed in every management review meeting.

Further we use Quality management system to determine and collect various requirement of customer at different stages and to get feed back of our customers.

ENVIRONMENT & SAFETY POLICY

We are committed to provide safe hazard free working environment as per international standard. Our plant is equipped with the following to provide a pollution Free environment.

1) Galvanizing Plant:

– Air scrubbing system to control air pollution & convert air pollutants in to water vapor.

– Water & effluent treatment plant to control solid waste & water pollution. The waste water is then treated for usage in gardening.

2) All Plants:

– Training, Workers Welfare, periodical medical checks with vaccination programs are carried out to ensure workers health & safe working atmosphere.