Overview

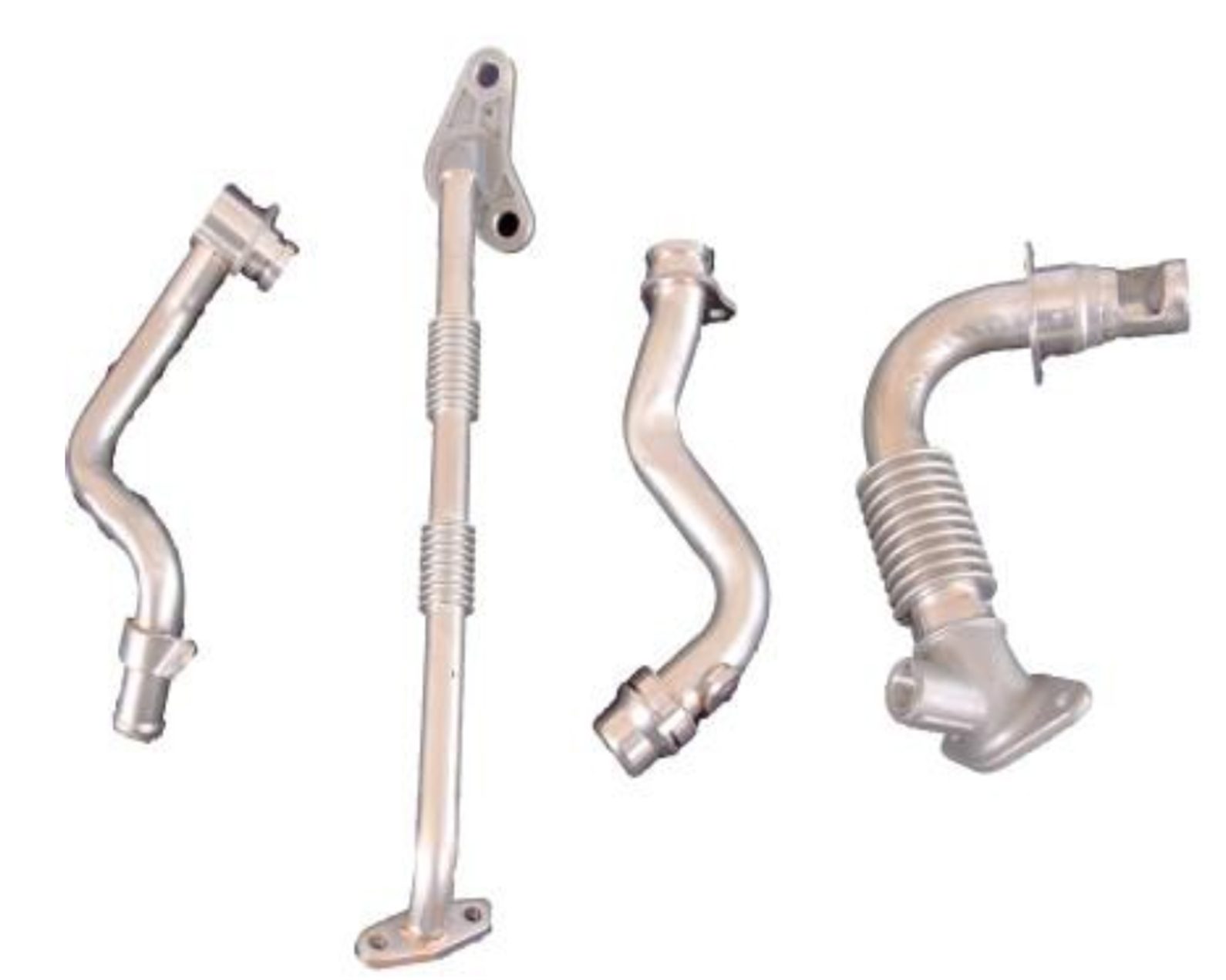

As a trusted industry leader in furnace brazing services, Poona Pressing is fully-equipped and promises to provide superior quality and value while meeting our clients’ unique project demands.

With the resources and experience to identify the precise process or cycle for your parts or assemblies, we can accommodate both simple and complex jobs so you get the most from brazing.

Inert atmosphere brazing

We have more than 30 years of brazing expertise. We have inert atmosphere brazing facility with brazing temperature above 800°C up to 1140°C.

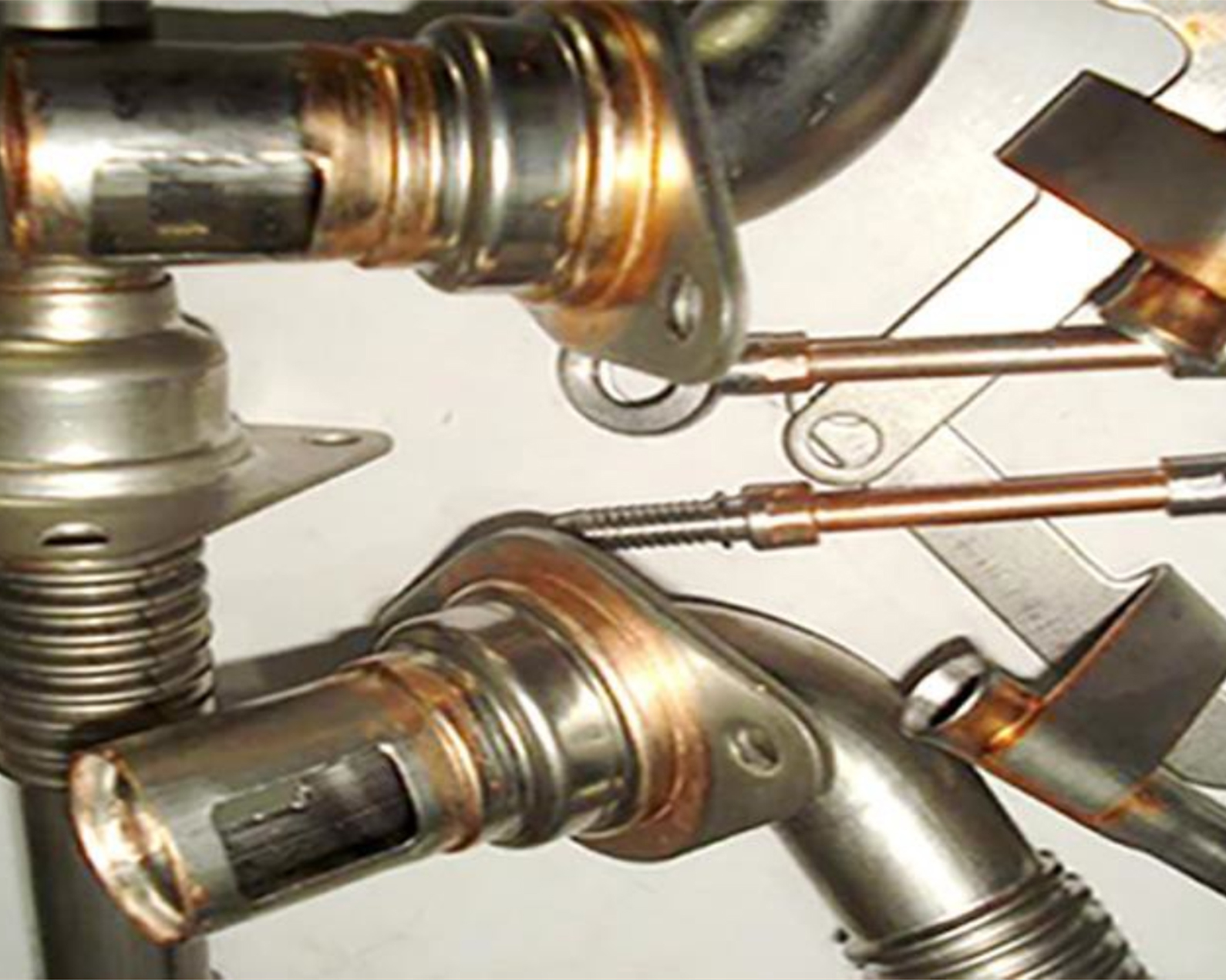

Best quality of brazing joint

Brazing process in controlled atmosphere

Suitable for large volume of production

Continuous conveyor type brazing process runs 24/7

No use of flux

Flux not needed for brazing which ensures clean and bright parts as compared to any other type of brazing

Consistency

Strict process control ensured by every hour monitoring of important process parameters.

Inert atmosphere brazing Capabilities

| Working max temp. | 1140 deg. C |

| Working Width | 160 mm |

| Working Height | 170 mm |

| Capacity in kg/hour | 60-65 kg |

Indogas Brazing Furnace

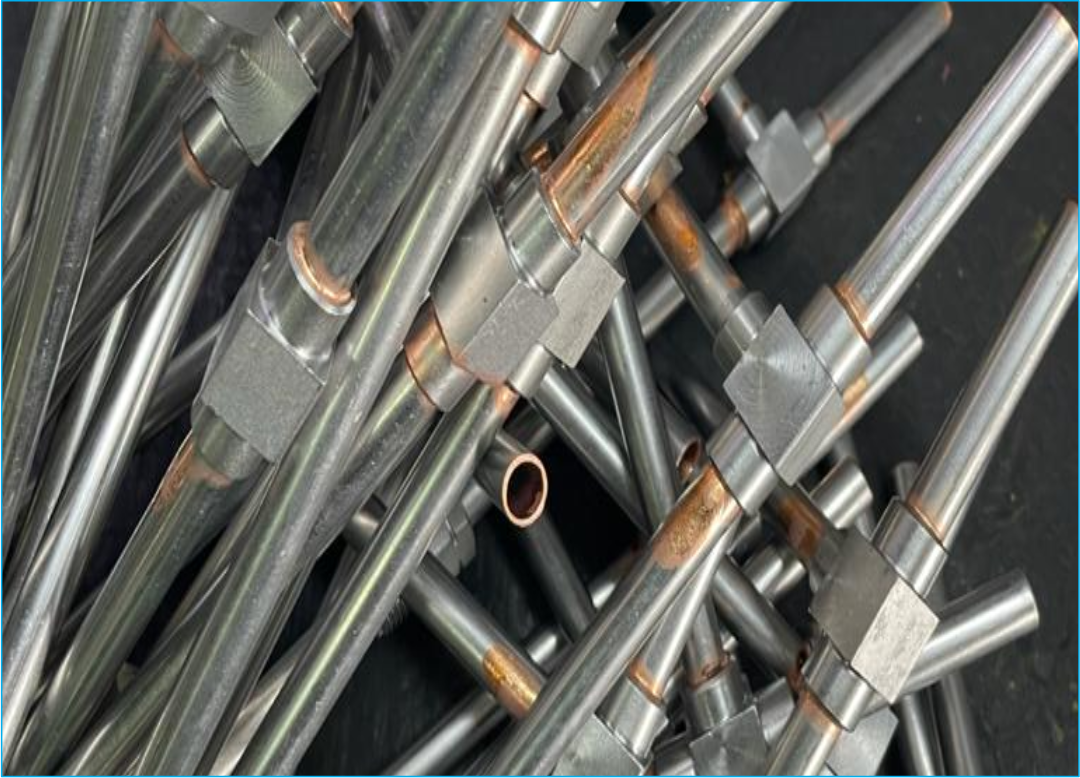

We can do SS to SS,MS to MS & SS to MS brazing by Cu, Nickel, Silver, Brass, etc. as filler metals.

Indogas Brazing Furnace Capabilities

| Working max temp. | 1150 deg. C |

| Working Width | 280 mm |

| Working Height | 140 mm |

| Capacity in kg/hour | 60-65 kg |