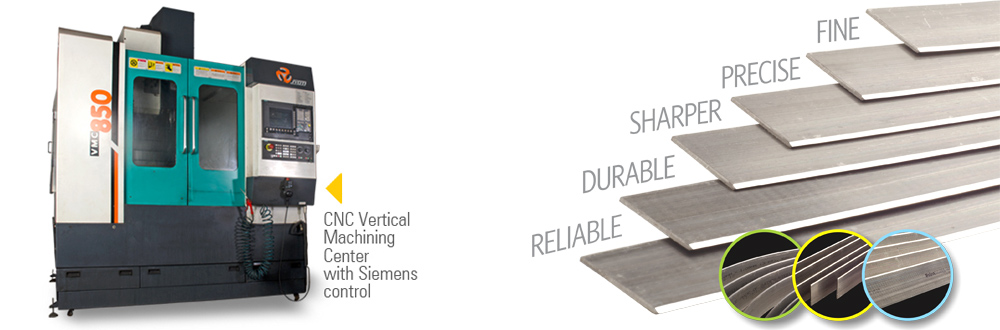

Cutting Creasing Rules

Center Bevel - Bevel is the type of cutting edge geometry, facilitated to give desired cutting and creasing result to the end use of packaging industry. Center Bevel means, the cutting edge is at the center of the rule thickness. Center Bevel edge is available in 42o and 52o. Choose any Bevel Angle suitable for your application.

Side Bevel - Side Bevel is also available in both 42o and 52o.

Center Bevel Long Edge - This bevel type is also available in both 42o and 52o as Top Bevel cutting angle. This type of bevel is useful in cutting soft material like foam, leather, cloth etc.

Through Hardened Rules - Through hardened edge rules have same hardness at body and the edge.

Edge Hardened Rules - Only the Tip of the rule is hardened to maximum possible and the body of the rule is soft in order to achieve better bend-ability with suitable run length of rules.

Cutting Creasing Rules - The Cutting Creasing Rules are available in through hardened type body with elliptical creasing edge profile to give desired creasing results in hardest possible board or paper. The bottom edge is flat base type with smooth chamfer on both sides to avoid any damage to the plywood boards at the time of fixing the rules.

Perforation Rules - The Perforation Rules are available as per the specifications given in the table below.

Zipper Rules - The Zipper Rules are available as per the specifications given in the table below.

| Thickness | Bevel | Spacing CUT / Non CUT | Height |

| 0.71 mm (2pt) 1.05 mm (3pt) 1.42 mm (4pt) |

Center side Center bevel Long edge |

1 : 1, 2 : 1, 3 : 1 | 21.3 mm to 25.4 mm |

| Thickness | Bevel | Tooth Spacing | Height | Angled Ratio |

| 0.71 mm (2pt) 1.05 mm (3pt) |

Center | 6mm, 8mm, 10mm, 12mm | 21.3 mm to 25.4 mm | 21.3 mm to 25.4 mm |