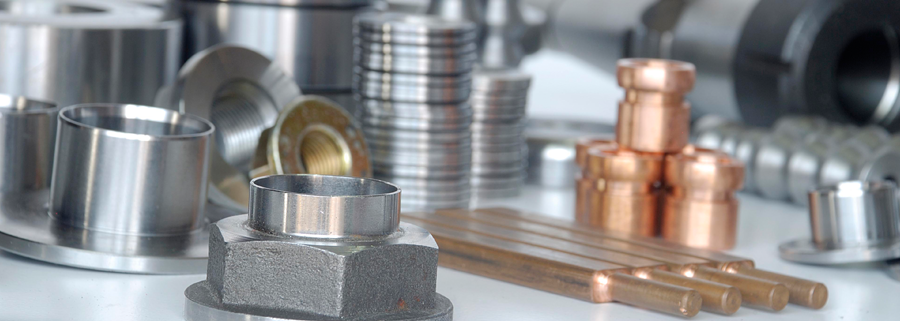

Our Product

Industrial Engineering Machines

- CNC Machines

- Industrial Shaft

- Industrial Washers

- CNC Machines Job Works

- CNC Turning Works

- Adapter

- Gear Shifter

- Gear Blank

- Copper Boll

- High Tensile Bolt Nuts

- Connecting Bush

Contacts

Pushpa Engineering

Address:-

sr no 11/1 shantinagar landewadi, Bhosari, Pune-39

Contact Person:-

Mr. Vitthal k Vetal

Mobile:-

020-46772374 (M), 9657755233

Telefax:-020-46772374

(M) 9657755233

Website:-

www.pushpaengineering.com

E-Mail:-

pushpa.engineering @gmail.com

Profile

Incorporated in the year 2006, at Pune, (Maharashtra, India), we, “Pushpa Engineering,” is a renowned name involved in manufacturing and supplying a wide range of Industrial Engineering Machines and Tools. Regularly updated manufacturing equipment with a combination of the most advanced technological procedures in the manufacturing processes have enabled us to manufacture Industrial Engineering Machines and Tools that can be depended on for trustworthy performance.

With a team of knowledgeable engineers and process specialists from the manufacturing industry, we a Sole Proprietorship firm, have been able to manufacture and supply Tool Room Job Works, Industrial Shaft, Industrial Washers, CNC Machines and Jigs of the finest quality. Our steady efforts and determined devotion levels have made us able to attain a significant turnover of Rs. 1 Crore (10 million INR) annually.

Our mentor, Mr. Vitthal Vetal, with his successful and inspiring leadership qualities, has enabled us attain a distinctive position in the industrial equipment and auto parts industry. Their extensive technical knowledge and management abilities have provided the entire organization with the required thrust to stay ahead of competitors.

Our Product

We work towards meeting the vast need of engineering equipment across different industries. Our range of components includes:

- orkCNC Machines

- Industrial Washers

- Industrial Shaft

- Jig

- Tool Room Job Works

Our Quality Assurance

Company is certified by AGSI for ISO 9001:2000

Our stringent control procedures and packaging procedures have aided us in maintaining the position as one of the renowned and famed manufacturers of Industrial Engineering Machines and Tools. The huge manufacturing unit is divided into departments facilitating specialization and departmental efficiency. We have a well equipped quality analyzing department with highly modernized equipment to meet the industry parameters across the levels of production. The machines and tools are operated by staff with sufficient technical expertise.

List of Machinery:

Tooling: - We have tooled up our machine with Seco, carmax, sandvik, vipul tools in order to achieve high accuracy and surface finish.

1. CNC Turning Centre :- 04 NOS

Model LMW & saffal-5

Make LMW & spm tools

Between Centre 400mm

Chuck Dia. 200 mm 165mm

Controller Fanuc – oi make

Power 7.5 KW continuous

1. Lathe machine: - 03 NOS

Lathe Machine size 5 Feet

Chuck diameter 250mm

Make Sheetal

Spindle bore 60mm

Centre height 12”

1. OTHER M/C

Mon-tear 01 no’s

Weir-cut 01 no’s

Press m/c 01 no’s

Drill taping m/c 01 no’s

Milling m/c 01 no’s

Quality Instrument:-

Instrument Range

1)Surface Plate -

2)Dial Vernier Caliber 0-300mm

3)Depth Vernier Caliber 0-150mm

4)Micrometer 0-200mm

5) Dial Comparator Stand 200mm.

6)Dials Lever type 2 micron & 10micron

7) Bore Gauge Mitutoyo Make 18-150 mm

8) Dial Plunger 10microns / 01 microns

9) Height Gauge 0-300 mm

10)V-Block Harden 100X95X70

11)Depth vernier 0-150mm

(A) At present we are supplying to following customers.

1) DJR Deluxe Bearings Ltd.

2) Rathi Transpower Pvt. Ltd.

3) Guru Nanak engineers

4) Jayshree Electrodevices Pvt Ltd.

5) LPS Bossed Ltd.

6) Tusco pumps Pvt Ltd.

7) S V Engineering

8) Arche componts pvt Ltd

9) Miju compontes pvt Ltd

In process: - mahenra & mahendra Ltd, involute gears ltd, Arihat components Ltd

Arm welder’s pvt ltd, krloskar numatik pvt Ltd, and any other company

Development stage urgent

(B) At present major buyers (Row material)

1) Manibhadra metal

2) Jeneswar steel center

3) Mahavir steel

4) Rohit steel

(C) Present outworking,

01) Sai engineering works

02) Susil enterprises

03) Vipul tool

04) Bharat enterprises

05) Visnavi industrs & Trade

06) Ganesh engineering

(D) Job Name: -

hi tensile bolt, main shaft, hub, sleeve, connector, pin, washer, pinion, sockets, Boll pin, Boll, pillar bush, internal drive shaft, link pin, drive, idler gear, etc.

Our Team

We are the dependable and rapidly growing traders of Tool Room Job Works, Industrial Shaft, Industrial Washers, CNC Machines and Jigs, backed by a team of specialized promotion and purchasing personnel, highly qualified and competent engineers and trading experts, who aid us to procure and supply a huge assortment of products as per the specific demands of our clients. Sufficient industry exposure, detailed product knowledge and an efficient approach of our workforce, enables us to make our existence felt across the national markets.

Why Us?

We have been triumphant in becoming one of the most successful names for Industrial Engineering Machines and Tools used in the industry across the nation. Some of the parameters that have continuously helped us to be better than every competition in the industry and lead the country’s markets are:

- Our components are designed & manufactured to give higher tolerance levels.

- Our components comply and meet leading national & international quality standards.

- We use fully tested high grade materials in our manufacturing processes.

- All our components are known to have long life and high performance levels.

Product Portfolio

We are into manufacturing and supplying an exquisite range of Machine Tool Accessories & Engineer's Tools of the finest quality for our clients spread all over the country. We manufacture and deal only in globally acclaimed products of the most perfect finishes and designs. As a result we are able to manufacture and supply Tool Room Job Works, Industrial Shaft, Industrial Washers, CNC Machines and Jig that are simple to use, dependable and long lasting.

We offer:

- Tool Room Job Works

- CNC Machines

- Industrial Shaft

- Jig

- Industrial Washers

Salient features:

- Reliability

- High precision

- Efficient performance

- High utility

- Cost efficient

Client Satisfaction

Client contentment and building healthy business terms with them have been our focus. Due to our state-of-the-art technology and high end fabrication processes, we have been able to manufacture as per our client needs. The products are supplied within the assured delivery schedules. Our capability to meet the bulk needs of our customers and our simple processes of payment has turned us into the choicest of manufacturers and suppliers in this industry.

CNC Machines

CNC Machines

Industrial Shaft

Industrial Shaft

Industrial Washers

Industrial Washers

Jig

Jig

CNC Machines Job Works

CNC Machines Job Works

Adapter

Adapter