Directors Profile

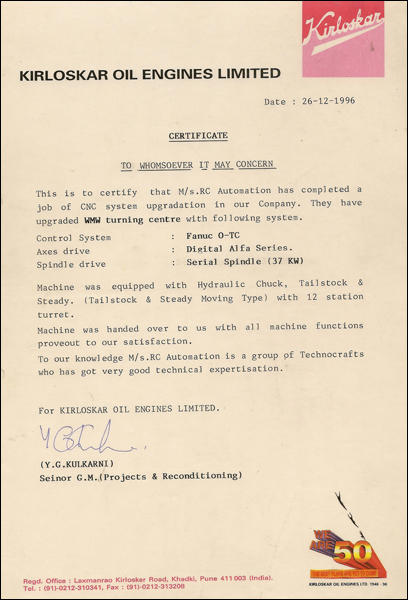

Electronics Engineer Started his Career in January 1989 with Bharat Forge Ltd., Pune as Maintenance Engineer. After gaining vital hands on experience for 5 years later joined Kirloskar Oil Engines, Pune as Maintenance / Project Manager. Decided to pave his own path by inception of RC Automation in the year 1996.

Work Experience : In the tenure of 20 Years, he had vital experience in Maintenance, Up gradation & Re conditioning of highly sophisticated CNC Machine Tools.

- Reconditioned and upgraded more than 150 NC / CNC machines under the banner of RCA.

- Handled many heavy and highly sophisticated machineries in the process of Installation and commissioning of CNC machine tools.

- Designed and manufactured CNC based Special Purpose Machines under RCA banner.

Mechanical Engineer Joined RC Automation in year 1996 with past experience of working with Star Vilkmann for 2 years & Fine Arc System for 1 Year. Started his carrier as Engineer in RC Automation and ascended to the position of working Partner.

Work Experience : In the tenure of 16 Years, he had vital experience in Up gradation & Re conditioning of highly sophisticated CNC Machine Tools. In addition involved in development of Micro controller based systems.

- Reconditioned and upgraded more than 125 NC-CNC machines under the banner of RCA.

- Handled many heavy machineries in the process of Installation and commissioning projects at RCA.

- Involved in to Design and manufacturing of CNC SPMs in RCA.

Electronics Engineer Joined RC Automation in year 1996.Started his carrier as Engineer in RC Automation and ascended to the position of working Partner.

Work Experience : In the tenure of 13 Years, he had vital experience in Up gradation & Re conditioning of highly sophisticated CNC and PLC based Machine Tools.

- Reconditioned and upgraded more than 100 CNC/ PLC controlled machines under the banner of RCA.

- Handled many heavy machineries in the process of Installation and commissioning projects at RCA.

Infrastructure

- Area (Works & Office) : 10,000 Sq.ft. built-up area on12,000 Sq.ft. Plot Full pledged office with all amenities and well connected with Fax, Internet, Telephones and office automation equipments.

- Electricity Power: Installed 3 Phase power capacity of 150 HP.

- M/c’s and Equipments : Bench Grinder, Magnetic based portable drilling m/c up to 35 MM capacity, Welding machine, Air Compressor 200 CFM, Bosch Cutter, Jig saw, Hand drills, Bench vice, All required tools and tackles etc.

- Measuring Instruments and Gauging Devices : Granite Surface plate (Grade 0), Granite Square master (600 x 600MM), Granite Rt. Angle master (450 x 300MM), Granite parallel blocks, CI parallel plates, Precision level bottles, St. edges, Height gauge (600 MM), Bore Gauge, Dial Vernier, Micro meters, Dial gauges both Plunger and Lever, different size dial stands, V blocks etc.

- Material Handling Equipments: Goliath Crane - Capacity 3 Tonnes. Hyd. Pallet lifter- 2 Tonnes.

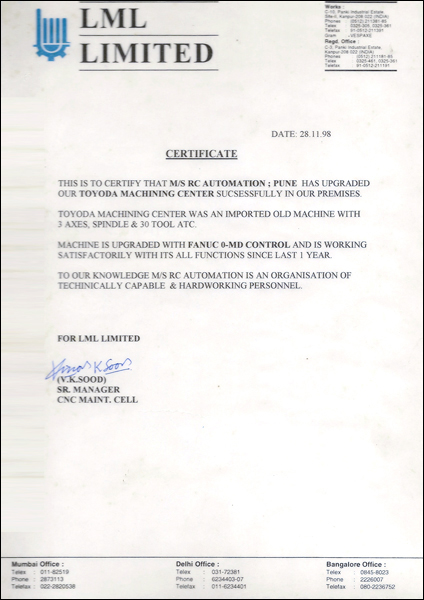

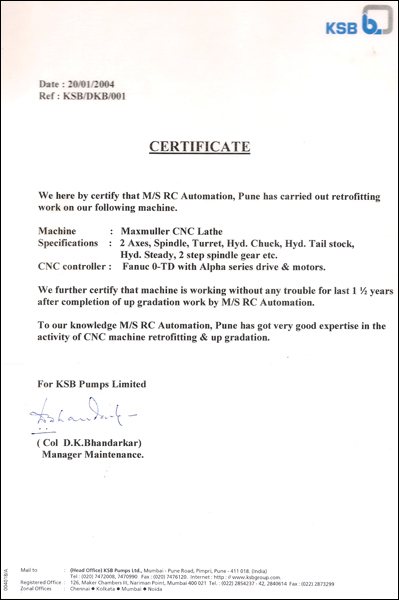

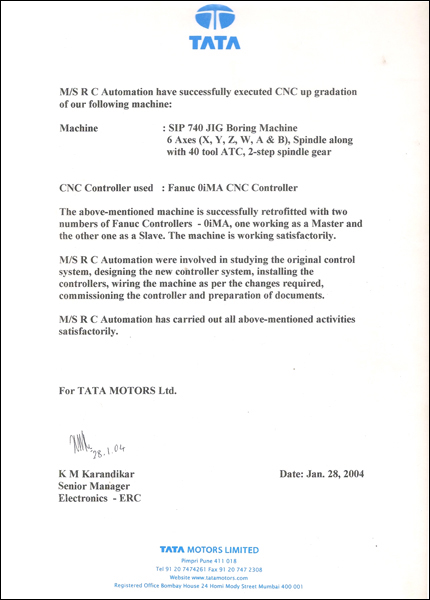

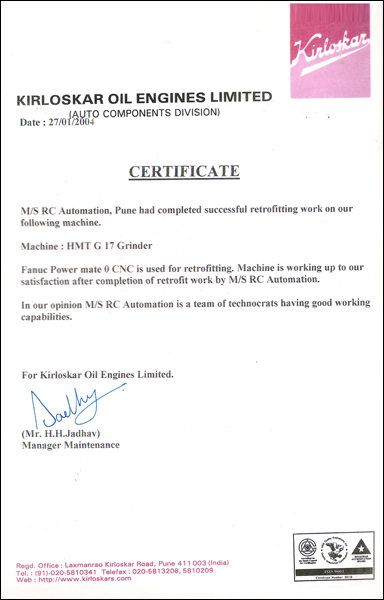

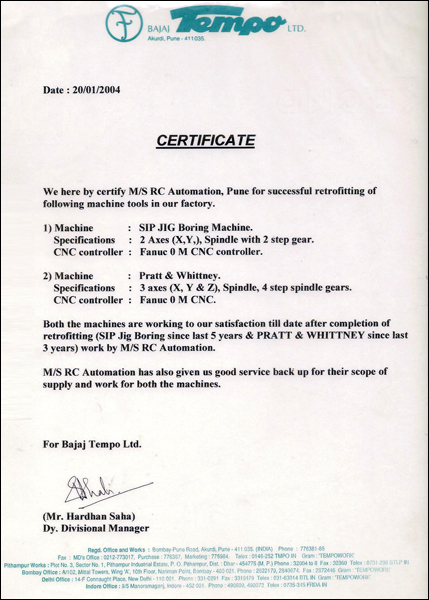

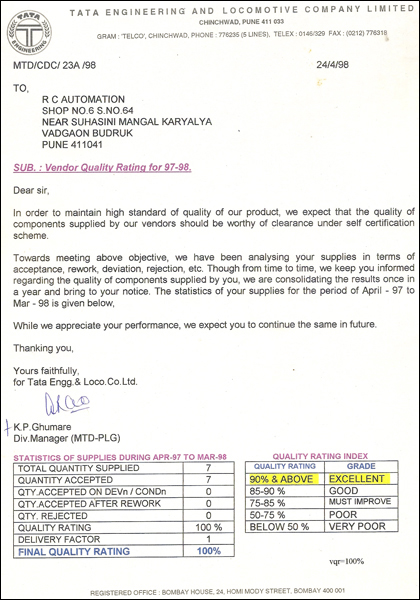

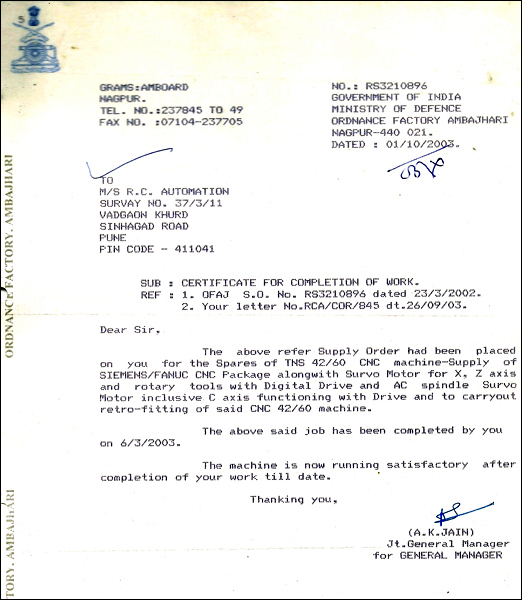

Awards and Achivements

- CNC System Up-gradation of more than 400 Machines.

- Mechanical Reconditioning of over 100 CNC Machines.

- More than 50 CNC - SPM machines Designed & Manufactured.

- Carried out Installation, Commissioning, Lifting & Shifting of more than 150 machines of different kinds, on turn key basis at various locations in India.

- Handled turn key projects throughout India.