Company Profile

Rechner Automation Systems Private Limited was incorporated in the year 1990. It was the culmination of coming together of two highly motivated and enterprising individuals each of whom had made his mark in reputed multinational corporations.

Mr. Vishwanath Ramchandra, a B.E in Instrumentation Engineering from Mumbai University has worked in well-known Multinational companies and implemented of a number of prestigious projects. His considerable expertise and in-depth understanding of the need and requirements of industrial automation systems enabled Vishwanath to set out as an entrepreneur in his own right. 25 years of experience in Process automation systems make Vishwanath and Rechner as leaders in the field.

Rechner Automation Systems Private Limited was incorporated in the year 1990. It was the culmination of coming together of two highly motivated and enterprising individuals each of whom had made his mark in reputed multinational corporations.

Mr. Vishwanath Ramchandra, a B.E in Instrumentation Engineering from Mumbai University has worked in well-known Multinational companies and implemented of a number of prestigious projects. His considerable expertise and in-depth understanding of the need and requirements of industrial automation systems enabled Vishwanath to set out as an entrepreneur in his own right. 25 years of experience in Process automation systems make Vishwanath and Rechner as leaders in the field

The Mission

Rechner long recognized that it is imperative for an industrial automation solution to be comprehensive, timely, elegant, cost optimal, scalable, and future-proof. It also emphasizes that various devices, components, equipment and techniques comprising the solution must be compatible and highly reliable. Further the system architecture and configuration must be customized to be user friendly, cost effective and with high availability.

Living by its beliefs, Rechner has become a leading one stop customized solution provider for process industries, allied utilities and services, furnace automation, Bulk Material Handling, energy conservation.

Rechner will continue to innovate and will strive to make further strides transcending all geographical barriers to be recognized as an international quality solution provider.

Customer Focus

– Mission defined by customer success.

– Behavior driven by customer satisfaction.

- Strategy defined by customer need (Product Agnostic).

The Bouquet of Services

– RECHNER offers a complete bouquet of services, which comprise a comprehensive industrial automation solution. The bouquet consists of

Consultancy, Design, Development, Engineering, Fabrication, Procurement, System Integration, Testing and Inspection, Installation and Commissioning, Quality Assurance, Project Management, Maintenance, Documentation Support.

• Customer Focus

– Mission defined by customer success.

– Behavior driven by customer satisfaction.

- Strategy defined by customer need (Product Agnostic).

• Technology Focus

– Wide product coverage.

– Enhanced Manufacturing Capabilities.

• The Field(s) of Operations

– RECHNER has implemented a number of projects in the following fields.

Steel making processes, Bulk Material Handling, Furnace automation, Plant Utilities and Energy Conservation.

RECHNER is keen to expand its horizons to include any new field in its operations and is eager to accept new challenges in industrial automation and Control & Instrumentation.

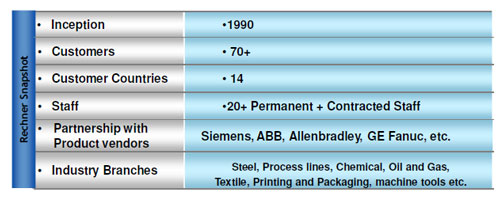

• Rechner - Snapshot

An Impressive Decade and Beyond.