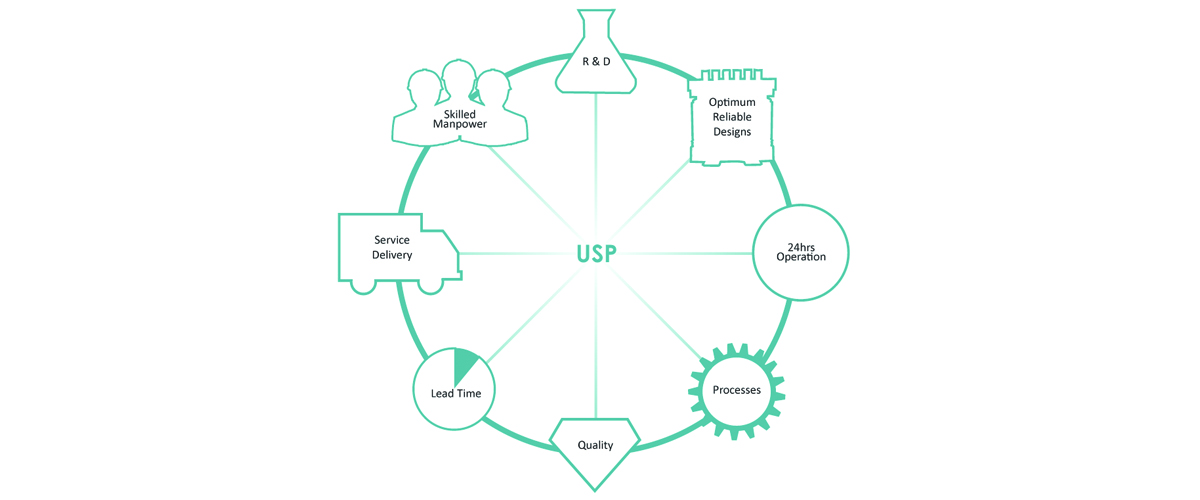

What Sets Us Apart

Our USPs

Following infographic illustrates our USPs that set us apart from competition.

Proactively Adding Value:

We strive to be seen as a partner who not only executes against our clients’ requirement but also provides the insights and thought leadership that fuel them. We consistently hear from clients and end clients that the way we deliver products by adding value and being engaged as a strategic partner is unlike anything they previously experienced. This type of proactive working and ownership over delivering excellent quality products happens every day throughout our organization.

Flexible and Customized Products:

Rishab Industries does not believe in a one-size-fits-all approach. We collaborate closely with clients to develop tailored, flexible solutions designed to suit specific needs and maximize results. The products we develop are follows are international standards and continuously evolving to meet changing demands of market.