PROCESS STUDY

Considering earlier process potential and commodity FMEA study, we found following recommended action is to be required for our new part development. .

PLASMA CUTTING

For over coming issue of taper cutting ,our plasma machine is fully super fine gas controlled machine. Gas pressure is adjusting by machine only selecting defined consumable.

FORMING / BENDING

Four side gauging is to be done in forming tool to avoid variation in height. Functional key dimension is to be controlled by poka yoke in forming tool and fixture.

WELDING

Considering the ref dimension importance , welding is to be planed in sequencing method to avoid distortion of welding. To minimize the welding spatter Co2 –argon welding is planned. All welder are qualified for 1G & 2G position by third party inspection as per section 9

Please contact us to let us know how we can be of assistance and be assured of our commitment to a rapid response.

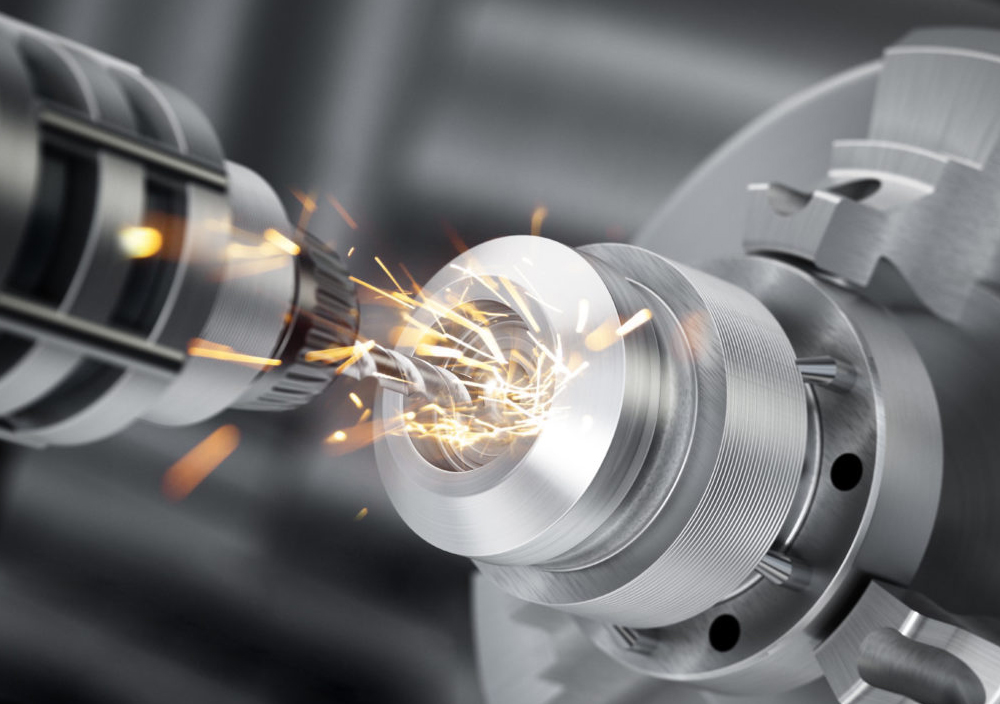

MACHINING

CNC TURNING (Max DIA 300 – 600 MM)

- VMC

- VTL 1000 Chuck Size

- CONVENTIONAL LATHE (Max Length – 1 M)

- MILLING MACHINES

- BAND SAW CUTTING (300 MM)

- RADIAL DRILLING MACHINES