About Us

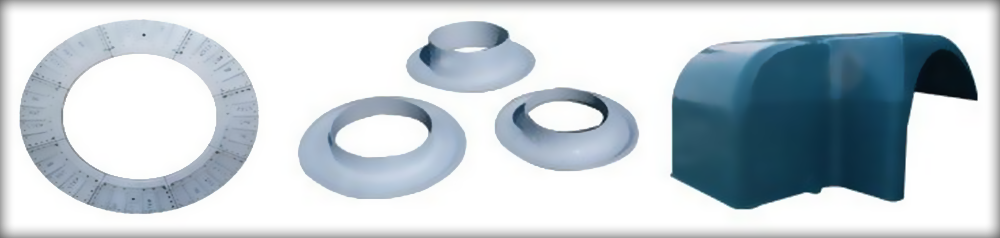

Established in the year 1996, Shashi engineering has been a fountainhead of innovation and practical application in the field of FRP products. The components by FRP are used across various industrial sectors. Our production gauge includes high end devices like the draft Tube Core, the Hemisphere Dome, Motor Cover, as well as Motor switch group. There is also a highly specialized Oil Vapor Seal Assembly and Operating Rod for 11kv VCB Runner Assembly.

In the past 14 years, Shashi engineering has evolved from being a motor component supplier to high end electrical equipment manufacturer. Successfully producing components for the electrical sub part industry across the nation. Our products have regularly been used in the following fields.

| Application Areas | Products |

| Hydro Generator | Oil Vapor Seal Assembly, Winding Shield Insulation Cap, Air Guide Assembly, Separator etc. |

| Switchgear and Rectifiers | Operating Rod 11kv, Heat sink covers, PFD fuse box assembly, Insulation washer |

| Hydro turbine | Bell Mouth, Spiral Casting, Draft Tube cone, Draft Tube Bend, Draft Tube Leg, Distributor Assembly for Pelton Turbine Model |

| Industrial Machines | Baffles, Stringing Blocks, Winding Support Rings. |

| Transformer | Insulated Core Bolts, Yoke Bolts, Tubes and other Fiber Glass Components |

| Foundry | Patterns for trunnion block, Butterfly Valve and Match Plates for Tube Castings. |

Shashi engineering works on the formula of division of work on departmental basis. As a manufacturing unit we are divided into administrative, technical, research and development sections. There is also a product development sector which works in close co-ordination with marketing and sales. The quality control team is completely independent of all other wings. All of these wings work together and hard, so that we could serve our clients with the best. The back bone of Shashi Engineering is business transparency and honesty. So that our customers come to trust us like no one else.

Company Profile

| Basic Information | |

| Business Type | Manufacturer |

| Supplier | |

| Exporter | |

| Ownership & Capital | |

| Year of Establishment | 1996 |

| Ownership Type | Sole Proprietorship (Individual) |

| Trade & Market | |

| Major Markets | Indian Subcontinent |

| Annual Turnover | Upto US$ 0.25 Million (or upto Rs. 1 Crore Approx.) |

| Team & Staff | |

| Total Number of Employees | Upto 10 People |

| Company USP | |

| Primary Competitive Advantage | Experienced R & D Department, Good Financial Position & TQM, Large Product Line, Large Production Capacity, Provide Customized Solutions |

| Quality Measures/Testing Facilities | Yes |

| Packaging/Payment and Shipment Details | |

| Customized Packaging | Yes |

| Quality Measures/Testing Facilities | Yes |

About Our Range of FRP Products and Components

Our valuable experience of the industry has guided us in carefully manufacturing the FRP products and components, which can be used in variegated industries. Our range encompasses of Baffle, Draft Tube Cone, FRP Hemi-sphere Dome, Main Cover, Cooling Box, Motor Cover, Motor Switch Group And Tape Changer Switch Group, Oil Vapor Seal Assembly, Operating Rod for 11kv VCB Runner Assembly and Spiral Casting.

Over the years in the industry, we have also sharpened our capabilities for manufacturing components for electrical equipment manufacturing companies as well as desired by them. Various application areas, where our products can be used are-

Application Area and Products

| Application Areas | Products |

| Hydro Generator | Oil Vapor Seal Assembly, Winding Shield Insulation Cap, Air GuideAssembly, Separator etc. |

| Switchgear and Rectifiers | Operating Rod 11kv, Heat sink covers, PFD fuse box assembly, Insulation washer |

| Hydro turbine | Bell Mouth, Spiral Casting, Draft Tube cone, Draft Tube Bend, DraftTube Leg, Distributor Assembly for Pelton Turbine Model |

| Industrial Machines | Baffles, Stringing Blocks, Winding Support Rings. |

| Transformer | Insulated Core Bolts, Yoke Bolts, Tubes and other Fiber GlassComponets |

| Foundry | Patterns for trunion block, Butterfly Valve and Match Plates forTube Castings. |

We also offer other product components like:

1) Model bearing cooling box

2) Fabrication of fluidized bed classifier(FRP)

Why FRP?

We at Shashi engineering believe in FRP as it could be successfully resolved to make highly efficient components of industrial and domestic use. FRP increases the Eco friendliness of the product and makes it far more versatile in design and application. Some of the major reasons for the use of FRP are:-

Light weight

Design flexibility

Corrosion resistance

High strength

Weather resistance

Design flexibility

Dimensional stability

Mechanical strength

High strength to weight ratio

Heat and sound insulation

Easily molded into complex shapes

Suitable for low volume production

Why Us

Some of the factors, which gives us a competitive edge over the other market players are-

High quality products

Capacious warehouse

Intensive R&D

Stringent quality checks

Competitive prices

Quality Assurance

Shashi engineering is a quality conscious organization, and strives its level best so as to win the trust of its clients through its quality control. The quality consciousness in our company is boosted by the presence of an independent quality control cell. This cell assures a quality check at every stage of production. Starting from picking the raw production material, until the final stages of delivery. A through quality is made along the following points.

Durability

Power Frequency

Mechanical Tests

Incoming Material Inspection

Final Inspection

Team

We believe in the spirit of team work. Our team is made of people who are brilliant and thoroughly qualified for the work and quality which they deliver. It is under the supervision of this team that the production gauge completes the cycle from production to delivery. The team is divided into departments which work in co-ordination, as well as independently, so as to deliver absolute quality of product and service. Shashi engineering maintains a series of workshops and examinations, so as to keep its team members sharp and up-to-date with the trade.

Clientele

We have been one of the frontrunner's of the industry and ensure that our products meet the international standards of quality. We have earned accolades from our clients spread all across the globe.

Some of the clients associated with us are -

BHEL, Bhopal

BHEL, Jhansi

CRWS, WC Railways, and Bhopal for FRP components.

Regional Research Laboratory (CSIR), Bhopal for FRP Separation Column, FRP Fluidized Bed Classifier etc.

WHAT IS FRP

FRP, or Fiber reinforced plastic is a form of polymer matrix based composite. The fiber used, is mostly of glass, or otherwise made using carbon or Aramid. Fiber reinforced plastic has seen its major use in automotive, marine, aerospace and marine engineering.

Clients and International Demand

We have forever maintained a policy of putting the client before everything else. With an aim of client satisfaction, Shashi engineers have a product development team at hand. This team keeps a close tab on customer demands as well as client satisfaction. This policy of ours has made us the favorite of global services in FRP. Some of our clients are:-

BHEL, Bhopal

BHEL, Jhansi

CRWS, WC Railways, and Bhopal for FRP components.

Regional Research Laboratory (CSIR), Bhopal for FRP Separation Column, FRP Fluidized Bed Classifier etc.

Contact Us

171, Sector H, Industrial Area, Govindpura, Bhopal - 462 023, Madhya Pradesh, India

Contact Person.:Mr. V. P. Bhardwaj Mobile.:+(91)-9826467222, Tel.:+(91)-(755)-2601513, Fax: +(91)-(755)-2687625

E-mail:shashiengg@yahoo.co.in, bhardwaj.vp@gmail.com