EPCOS

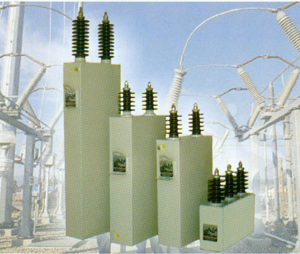

Medium Voltage Capacitors

Medium Voltage Power Factor correction directly related to the technical management of transmission and distribution network. The major benefits are :

Medium Voltage Power Factor correction directly related to the technical management of transmission and distribution network. The major benefits are :

Power quality . Increased voltage profile in substations and at receving ends.

Improving the operating cost of an installation. Decreasing reactive power demand and therefor reduction of apparent power with two highly important aspects.

Reducing losses

Increasing the performance of transformers and installation.

Power quality, voltage level

There are two possible situations : controlling voltage in substations and at reveiving end of medium voltage distribution lines.

Controlling Voltage at substations.

Controlling Voltage at substations.

One of the most critical point in the distribution of electrical energy is maintaining voltage at receiving end. The most usual crition is maintaining medium voltage above its nominal value.

To achieve this Medium voltage Capacitor banks are used. In fact a voltage rise may appear by connecting capacitor banks at the point of connection.

* Controlling voltage at the reveiving

Capacitor case

Capacitor case

The CRFA stainless Steel container is treated with a primer and finish coat of paint suit the application end of distribution lines.

Voltagea at receiving ends nomally decrease because of every long length of conductors / cables. This is of imprtance in area of rural distribution or where consumers are widely dispressed.

v

If capacitor banks are installed at the end of line that shall decease voltage drop losses in conductors / cables.

Improving the operating cost of an installation

Generation, transmission and distribution of energy are responsible for a significant degree of energy losses.

These losses may be divded into :

* Losses in generation station and MV/HV substances.

* Losses in transmission system

* Losses in HV/MV substation.

* Losses in distributopn line.

The best way of reducing losses in an MV distribution lines is the installation

I2R Losses in line P (KW) = 3 R. I2.L

Reactive consumption in line Q (KVAr) = 3. x I2.L

Reduction in losses after installation of capacitor Δ P = R [p2 +(Q-Qc)2] / V2. L

P = Active power, Q = Reactive without capacitor, QC = Capacitor bank in MVAr, I = Current,

V = System voltage in KV, R = Resistance in Ohms/Km, X = Reactance in Ohms / Km, L = Length of line in Km

. Manufacturing Characteristic of M.V. Capacitors

. Basic Construction

High voltage capacitors employ a technique wherein the dielectric comprises several layers of polyprolylene film

impregnated with an insulating fluid. Electrodes are made from thin aluminium foils. A high voltage capacitor is made of a number of elements connected in a series - parallel arrangement. The total number of elements isdetermined operating voltage. Depending on capacitors rating each elements can be fuse protected.

After impregnation the complete assembly is hermetically sealed inside a steel container.

The Dielectric

The all-film dielectric used in high voltage capacitors is manufactured from the most advanced polypropylene film available which has the following benefits :

Reduced dielectric losses

Decreased variation of capacitance with ambient temerature, to obtain a more constant output

Impregnating Medium

The impregnation fluid, has has been specially formulated for power capacitors. It has been selected for both its physical and electrical properities and its high resistance to extremes of temperature. The fluid is non chlorine bio-degradable and contains no PCBs.

Internal Element Fuses

Modern power capacitors are designed to withstand high stresses where the electric gradient in the dielectric is typically in excess of 50-60 volts per micron. Depending on the voltage rating the capacitors in EPCOS range incorporate highly efficient back-up protection so that each individual element is safeguarded by a built-in, series connected fuse. In The event of a localised breakdown of the electric, only the faulty element is disconnected by the fuse and any subsequent reduction in capacitor output is minimized.

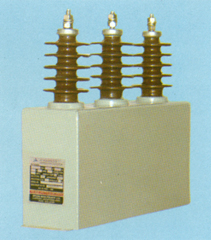

Capacitor Case

The CRCA container is treated with a primer and finish coat of paint to suit the application.

Capacitor Bushing

Depending on requirements, one teo or three porcelain bushings are fitted to the container. These have impulse withstand rating of 75KV, 95 KV, or 150 kV according to application.

Standards

IS- 13925 / 1988 ( supersending the old

IS : 2834-1986), IEC 871-1, IEC 871-1, IEC 871-2.

Shut capacitors for AC power system having rated voltage above

| Capacitor Units | |

| Type healing Dieelectric | Welded CRCA Stainless Steel tank, Liquid design, non-self Polypropylene film, |

| Impregrant | Non PCB film |

| Connections | 1-phase / 3- phase units (depending on voltage rating) |

| Tolerance on capacitance | -5 % + 10 % |

| Discharge mechanism | Discharge resistance provided |

| Discharge time | < 50 V within 10 min |

| Capacitor unit protection | Internal / External fuses depending on rating |

| Total looses including discharge resistors | < 0.2 watts / KVAr |

| Rated Voltage (Vn) | As per requirement of capacitor bank voltage |

| Rated frequency | 50 / 60 hz |

| Inslution level | As per requirement of capacitor bank voltage |

| Continuos over voltage | 1.1 x Vn (rated voltage) for 12 hrs daily |

| Continuos over current | 1.3 x In (rated current) |

| Temperature range | -25 0C to + 50 0 C |

| Capacitor Tank | |

| Type | Inddor / Outdoor |

| Connections | 1 - phase / 3-ph Detta / Si |

| Terminal arrangement | Outdoor on post inslulators Indoor Cable entry hole / Box as per customer requirement |

| Bus bar material | Aluminium Copper as per customer requirement |

Recommended Capacitor Bank Protection

This shouldbe designed to protect the capacitor bank against overloads current. With the modern low loss capacitor, the risk of thermal breakdown, the risk of thermal breakdown is minimal and any failure more usually results from dilectric breakdown. This occurs as a result of over voltage which, in many cases, is caused by excessive harmonic current. Protection can be achieved by means of peak value voltage sensitive relays or current relays having characteristics designed to prevent over voltage.

Where capacitors are connected to a network fitted with fast reclosing breakers, they must be fitted with undervoltage protection to ensure disconnection at voltage drop-out. They must not be reconnected until the residual voltage has fallen below 10 % of the rated value.

External Fuse protection

External fuse can be used to provide protection for individual capacitor units and the smaller capacitor bank. The selected fuse rating must take account of overvoltages overcurrents and switching transients such that spurious operation is avoided.

Unbalance Protection

The purpose of unbalance a faulty bank before overvoltages greater than 10% appear on remaining healthy units. To achieve this, the capacitor units are arranges in single star or double star connections. In case of single star protective relay can be operated by sensing voltage unbalance across by RVT whereas in case of double star protective relay can be operated by sensing fault current of CT connected between neutral of two stars.

Damping Reactors

When switching a capacitor bank, high current transients appear. These can be particularly high if the bank is connected in parrel with another bank which is already energised.

It may, therefore, be necessary to limit this inrush current by connecting a reactor in series with the capacitor bank.

Enclosures

A complete range of enclosures can be offered to suit all the applications, selected from:

* Ingress Protection ratings up to IP55 for indoor or outdoor use.

* Cubicles, tanks o open racks, floor mounted.

Asociated Equipments

All the following equipments can be offered :

* Controlling switchgear for manual or automatic control.

* Voltage and current transformers.

* Current limiting reactors, Detuning and filter reactors-iron and air-cored.

* Out-of-balance protection systems and Lightning Arrestors.

Information required with enauiry

* Requirements is new or for replacement

* Dimensions of existing units in case of replacement

* Highest system voltage and frequency.

* Temperature category.

* Rated output required in KVAr.

* Single phase / Three Phase.

* Connectiom : Star / Double Star / Delta

* Basic Insulation level

* Location : Indoor / Outdoor

* Fuses : Internal / External Fuse.

* Type of load.

* Single line diagram of the electrical system

* harmonic details if available

* Protection required

* Associated equipmets required.