About Us

Established in 1995, ISO 9001:20008 Certified since June-2004.

Established in 1995, ISO 9001:20008 Certified since June-2004. Specialized in Various Diesel Engine Components & Assemblies’ Successful Development in Polymers to Achieve Excellent VAVE for KOEL (All Plants) & Greaves

Specialized in Various Diesel Engine Components & Assemblies’ Successful Development in Polymers to Achieve Excellent VAVE for KOEL (All Plants) & Greaves

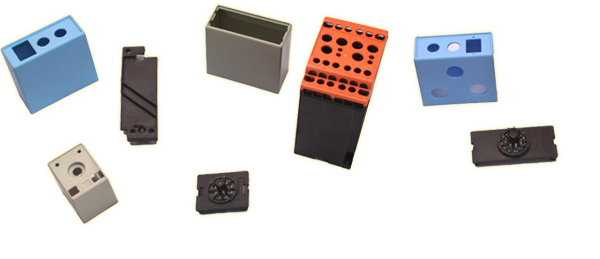

Cotton Ltd. (Pune Plant) Expertise in High Precision Injection Molded Components in various engineering polymers, such as PC, PCABS, ABS, Unfilled & Glass Filled PA 6/66, MINLON, POM,

Expertise in High Precision Injection Molded Components in various engineering polymers, such as PC, PCABS, ABS, Unfilled & Glass Filled PA 6/66, MINLON, POM,

SAN, HIPS, Zytel, etc & various Special Grade, Super Tough Polymers for related applications.

Our Developments

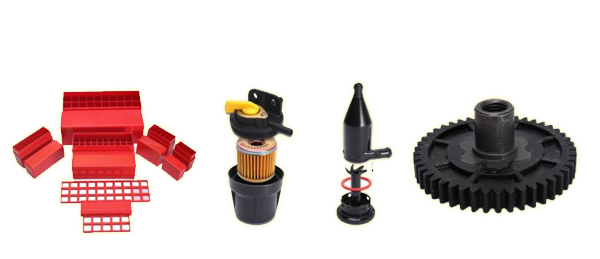

Successfully Converted Water Manifold Assembly for 2,3 ,4 & 6 Cylinder Engines in Polymer without affecting the Function & Performance of the part.

Successfully Converted Water Manifold Assembly for 2,3 ,4 & 6 Cylinder Engines in Polymer without affecting the Function & Performance of the part. Successfully Converted Spout Assembly, Thermostat Housing, Cylinder Head Rocker Cover & Support for Push Rod Tube from Steel Machined To Polymers.

Successfully Converted Spout Assembly, Thermostat Housing, Cylinder Head Rocker Cover & Support for Push Rod Tube from Steel Machined To Polymers. Apart from above mentioned parts & assemblies, also developed various other parts used in Diesel Engines.

Apart from above mentioned parts & assemblies, also developed various other parts used in Diesel Engines.

Infrastructure

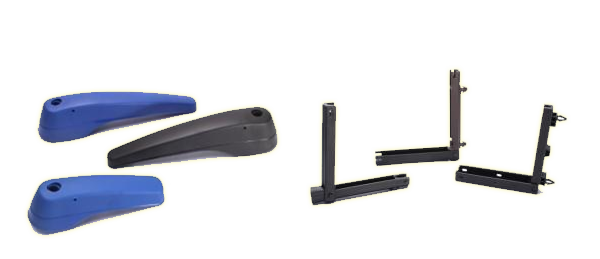

Total Plant area of Standard Plastics is 5000 Sq ft Plus Storage Area of 4500 Sq Ft for Raw Materials & Finished Goods.

Consists of 10 Microprocessor Controlled Injection Moulding Machines ranging from 40 T to 150 T.

Consists of 10 Microprocessor Controlled Injection Moulding Machines ranging from 40 T to 150 T. Assembly & Testing Set up for Parts & Assemblies.

Assembly & Testing Set up for Parts & Assemblies. In-house Service Tool Room for Mould Manufacture & Maintenance.

In-house Service Tool Room for Mould Manufacture & Maintenance. Standard Room for Inspection of Parts consisting of Instruments such as Surface Table, Slip Gauges, Height Gauge, Sine Bar, etc.

Standard Room for Inspection of Parts consisting of Instruments such as Surface Table, Slip Gauges, Height Gauge, Sine Bar, etc. Basic Accessories such as Mould Temperature Controllers, Hopper Driers & Hopper Loaders are installed for Better Productivity & Quality Control.

Basic Accessories such as Mould Temperature Controllers, Hopper Driers & Hopper Loaders are installed for Better Productivity & Quality Control. The Entire Plant Area is under CCTV Surveillance thus ensuring security of the plant.

The Entire Plant Area is under CCTV Surveillance thus ensuring security of the plant.

Certification