Our Products

Contact Us

Subhash Mechanical Works

Contact Person

Mr. Hardial Singh

Address :

888/2 , Industrial Area A , Back Side Veenus Ind. Corpn. - Ludhiana.

Tel :+91-161-2221118 , 4620118 , 4640118

Mobile :98144-84820, 93574-07300

About Us

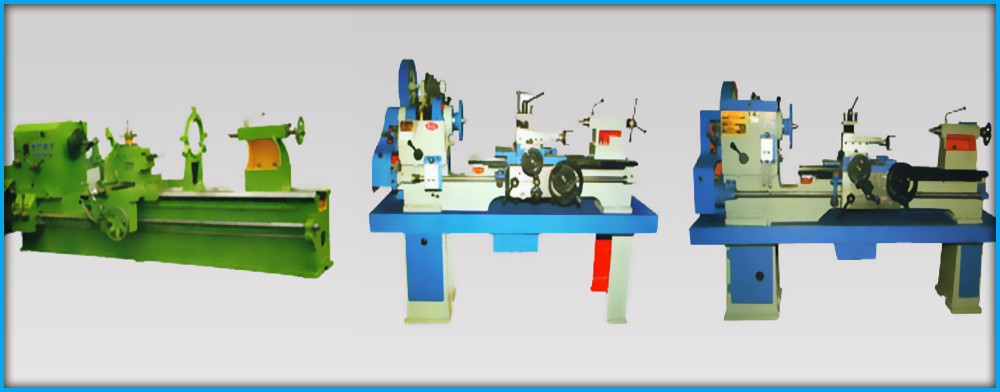

Subhash Mechanical Works which is providing customer oriented services since 1953. we Subhash Mechanical Works, are a reputed organization involved in manufacturing and supplying a comprehensive range of 6.5 & 8.5 Feet - Lathe Machines. Clients recommend our products for their corrosion-resistance, longer functional life and abrasion resistance. In addition to this, these are used in metal spinning, wood turning and to produce screw threads. Furthermore, our efficient workforce develops these machines using excellent range of spare parts and high-grade raw material.

We are committed to serve our clients by providing them fine quality lathe machines. Furthermore, we manufacture these efficient machines using superior quality spare parts. We procure the raw material from world renowned vendors, who are known for offering quality assured products to the clients. Moreover, we have hired a team of dexterous professionals, which works with utmost dedication in this age of cut throat competition. Due to our transparent dealings and ethical business philosophies, we have mustered a huge client base across the nation.

We have achieved progressive success in this domain under the noble guidance of our mentor, Mr. Hardial Singh. Due to his dynamic leadership skills and vast industry knowledge, we have always stay ahead of our counterparts.

Company Profile

Basic Information

- Business Type

- Supplier

- Manufacturer

Ownership & Capital

- Year of Establishment

- Ownership Type

- 1953

- Owner

Team & Staffl

- Total Number of Employees

- No. of Research / QC Staff

- No. of Skilled Staff

- Upto 10 People

- 1 - 5 People

- 1 - 5 People

Company USP

- Quality Measures/Testing Facilities

- Yes

Packaging/Payment and Shipment Details

- Payment Mode

- Cash, Cheque

Product Detail

Our organization is offering a wide range of Heavy Duty Lathe Machines to our clients. Our professionals develop these products using quality tested raw material and heavy machinery. These excellent quality products consist of tail stock spindle, head stock spindle, flame hardened bed ways and apron.

Details of construction of the machinery:

Bed is made by using best-in-class cast iron checked strictly through micro-level & straight edge

Flame hardened ways of bed

Head stock spindle is manufactured using excellent quality steel

For lever type arrangement of automatic feeds apron is enclosed using oil bath system

Alloy steel used in making tail stock spindle is hardened and ground in nature

Utmost care is taken while procuring the raw material from the vendors

Each component is tested carefully by our quality testers

Leveraging on the knowledge of our professionals, we are offering a complete range of Extra Heavy Duty Lathe Machines. These are recommended by our clients for their robust construction and high tensile strength. Our range of extra heavy duty machines is manufactured using superior quality raw material and components.

Our Team

Our team of assiduous professionals is the prime factor for the growth and success of the organization. Due to their different domain expertise, we have been successfully catering to the needs of our clients. Owing to their meticulous efforts and technical know-how, we are fulfilling the minute requirements of the clients in an exact manner. These professionals work in close coordination with each other to achieve the desired objective of the organization.

Team of our qualified professionals includes:

Procuring agents

Engineers

R & D experts

Quality analysts

Skilled workforce

Quality Assurance

Being a quality conscious organization, we strive to maintain quality at each level of production. Quality auditors employed by us conduct stringent quality tests at our fully-equipped testing unit. These professionals test these machines using advanced testing equipment and modernized machinery. Furthermore, our professionals procure our raw material and spare parts from renown vendor base. Due to our adherence to international standards and quality, we are able to manufacture excellent quality machinery for our clients.

Our Infrastructure

Considering the need of developing our vast product line, we have best-in-the class infrastructure at our premises. Our infrastructure is well-equipped with requisite machinery and highly advanced technology. Furthermore, all our divisions are well manned by our qualified professionals. Due to the usage of sophisticated technology, we are able capable in handling bulk orders. In order to manufacture our vast product range, we have segregated our infrastructure unit into various divisions:

Manufacturing unit

R & D unit

Quality testing unit

Administrative unit

Research and Development

In order to remain at par with the international standards, we have established a well-equipped R&D unit at our premises. We have installed advanced machinery and latest technology at our R&D unit. Our R&D experts engaged in innovating new products, in order to fulfill the future demands of the clients. These professionals constantly guides the production management to develop world-class machines for our variegated client base. They regularly conduct market survey in order to remain with the prevailing market trends.

Client Satisfaction

As a client-centric organization, we have carved a niche in the domain of manufacturing and supplying a vast range of Lathe Machines. Because of excellent quality of our products and its variegated advantages, we have gained a huge respect in the industry. Furthermore, our professionals stay in constant communication with the clients, in order to get their feedback. In order to attain utmost client satisfaction, we strictly adhere to the industry standards while developing the vast range of machines.

Why Us ?

Our organization is manufacturing and supplying a wide range of Lathe Machines for our clients. The range of our machines is highly acknowledged in glass working, metal spinning and used for producing solids of revolution. Our machines are admired for their abrasion resistance, low-maintenance and precision-engineering.

Factors that make us ahead of our counterparts are as follows:

Well-integrated infrastructure

Dexterous workforce

Streamlined business operations

Competitive prices

Countrywide distribution network

Timely delivery