Profile

Incepted in the year 1977, Sugo industries is a manufacturer of heavy industrial fabrication. We are among the proudly proclaim in the industry in providing most experienced and specialized in delivering quality products. Our company is specialized in offering our esteemed client with vigorous quality welding services in delegating to BHEL and many other multinationals.

Our mentor Ashok Kharb, have come a long way since our beginning and are still progressing with full vigor to surpass all heights in the industry. Leveraging on our ultra-modern designing and fabrication facilities, we are able to customize our range such as stay ring, transformer tanks, water box, stainless steel welding, etc, as per the needs of our clients. Moreover our ethical code of conduct and timely delivery schedules has elevated the satisfaction level of our clients to great extent.

Owing to our stringent quality measures we are confident that our industrial equipments are at par with the international standards and are capable of meeting high performance demands of our clients. We lay strong emphasis on research and development; thereby fabricate advanced and technologically leading equipments that are economical for our clients.

Company Profile

| Basic Information | |

| Business Type | Manufacturer |

| Exporter | |

| Ownership & Capital | |

| Year of Establishment | 1977 |

| Ownership Type | Sole Proprietorship (Individual) |

| Trade & Market | |

| Annual Turnover | US$ 1-10 Million (or Rs. 4-40 Crore Approx.) |

| Major Markets | Indian Subcontinent |

| Team & Staff | |

| Total Number of Employees | 26 to 50 People |

Company Profile

Incepted in the year 1977, Sugo industries are a prominent manufacturer & supplier of heavy industrial fabrication products such as stay ring, transformer tanks, water box, stainless steel welding, etc. Owing to our capability of delivering highly specialized range we have been able to carve a niche for ourselves in the domain. Our endeavors have helped us in catering prestigious clients such as BHEL and many other multinationals.

Under the able guidance of our mentor Ashok Kharb, we have come a long way since our beginning and are still progressing with full vigor to surpass all heights in the industry. Leveraging on our ultra-modern designing and fabrication facilities, we are able to customize our range such as stay ring, transformer tanks, water box, stainless steel welding, etc, as per the needs of our clients. Moreover our ethical code of conduct and timely delivery schedules has elevated the satisfaction level of our clients to great extent.

Owing to our stringent quality measures we are confident that our industrial equipment are at par with the international standards and are capable of meeting high performance demands of our clients. Our constant endeavors have helped us a substantial turnover.

Products Profile

Our range of quality control industrial fabrication products are manufactured using supreme grade of raw material such as steel, aluminum, copper etc. which offers durability to the machines. Our range encompasses Transformer Tanks, Hydro Turbine / Generator assemblies like Stay Ring, Stator Frame, DT Liner, DT Cone, Runner Envelope, Regulating Ring, Pivot Ring, and other heavy fabricated Items.Water box & Shells, Air Slides, SS Welding, Turbine Housing, Heavy Fabrication, Bus Duct, Bus Bar and Aluminium Flexible Connection.

Additionally, we also offer custom made solutions to our clients across the globe so as to gain optimum customer satisfaction.

Quality Policy

Sugo Industries believes in offering to its clients innovative and high quality products. For this purpose we have a dedicated and highly committed team who work day in and day out to ensure that our products are world class. Sugo's Quality Control Departement in equipped to conduct through inspection of all manufacturing processes at various stages . Procedures conform to gauges and inspection equipment are calibrated in accordance with standards.

Third Party Inspection::

A) NTPC

B) NPC

C) SGS

D) Lloyd's Register

E) Indian Railway

Infrastructure

Sugo Industries has capacity to Handling most Intricate welding jobs having trained man power for :

Welding:

A) SAW

B) MIG

C) TIG

D) Rectifier

E) Generator

Fabrication:

A) Rolling Machine

B) Break Press

C) Punching

D) Drilling

Handling Capacity Up to 80 Tons.Lifting HT of 50 FT.

Testing of Welds:

Magnetic paricle, utrasonic Dye, penetrant method , Radiographic X-Ray.

Testing of leakages:

Pressure, vacuum, Gravity and kerosene testing

Team

We have reinforced our long term relation with our clients due to the consistent efforts of our workforce. Based on the hard work and intensiveness of our team members towards their work, we have reserved a position of great repute for ourselves in our country. We have a team of technicians, casting experts, mechanical and technical engineers and metallurgical experts who work in unification to provide best quality fabrication products & services to our clients.

Our quality auditors maintain a strict approach in inspecting the quality of our products so that only flawless products leave our premises. We owe the innovativeness and consistent improvisation of our manufacturing processes improves products. Our term is complete with personnel handling sales, purchase, marketing, administration, packaging and other activities that are necessary for our business to flourish in a proficient manner.

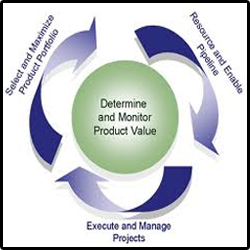

Research & Development

We have a full fledged research and development wing that facilitates us in providing heavy industrial fabricated products as per the latest advancements in the industry and specific requirements of our clients. Based on the intensive research and analysis of our R&D personnel, we are capable of designing technologically advanced and highly performance-oriented industrial equipment and components.

Our R&D personnel are engaged in finding ways to up-grade our facilities and conduct exhaustive research and market study which enables them to help our production team to introduce innovative production and testing methodologies that proves cost effective as well as beneficial for our company.

Our Undertaking

From the past 3 decades, we are offering our esteemed clients with vigorous quality welding services. We have numerous prestigious power projects off-loaded to BHEL including various multinationals.

We have successfully executed several prestigious contracts which included the following type of jobs:

- Aluminum and Copper Bus bar and Bus ducts

- Transformer tanks with Accessories

- Intricate steam and hydro turbine jobs

- L P inner Cylinders

- Stator frames & hydro generators parts

- Fabrication of Dam Gates

- Base frame for Motors

- Diesel engines & various installations

- Fully air conditioned Bunk houses (AC PCR / DC PCR Power pack)

- Diesel generators at oil Rigs

- Oil/Gas tankers/Pressure Vessels/HP Heater shells/Re-heater shells

- Stainless steel/ Mild-steel Reactors with SS/Fiber glass/Rubber linings

- 33 KV/66 KV Circuit breakers & Control panels

- Heat Exchangers, Tubular Reactors &Low /High Pressure Storage Tank

Director's Desk

We have always valued our customer's time and money and are committed to give our customer in time delivery at competitive prices. We beleive in providing the best solutions to our coustomers. Our ultimate objective is to be the No. 1 solution provider. Ashok kharb began his term in 1990 completing Engineering. He joined as CEO and over the years have increased the customer base by continues dedication and commitment.

Our Customers

Our Valued Customers:

- BHEL

- Hindalco

- Simens

- V A Teh Hydro India

- Crompton Greaves

- Graphite India

- HEG

- INDAL

- Grasim

- Balco

- Malco

- Maruti Udyog

- EMCO & Others