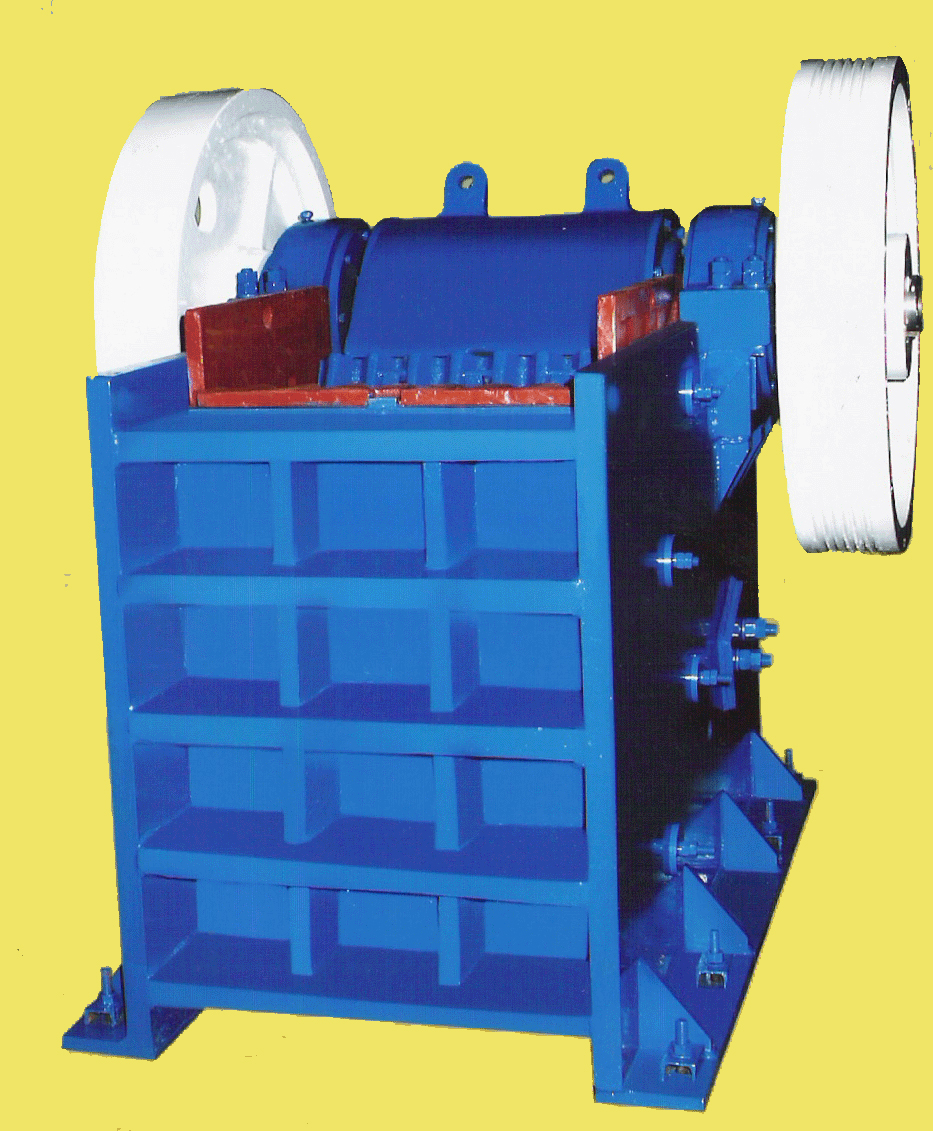

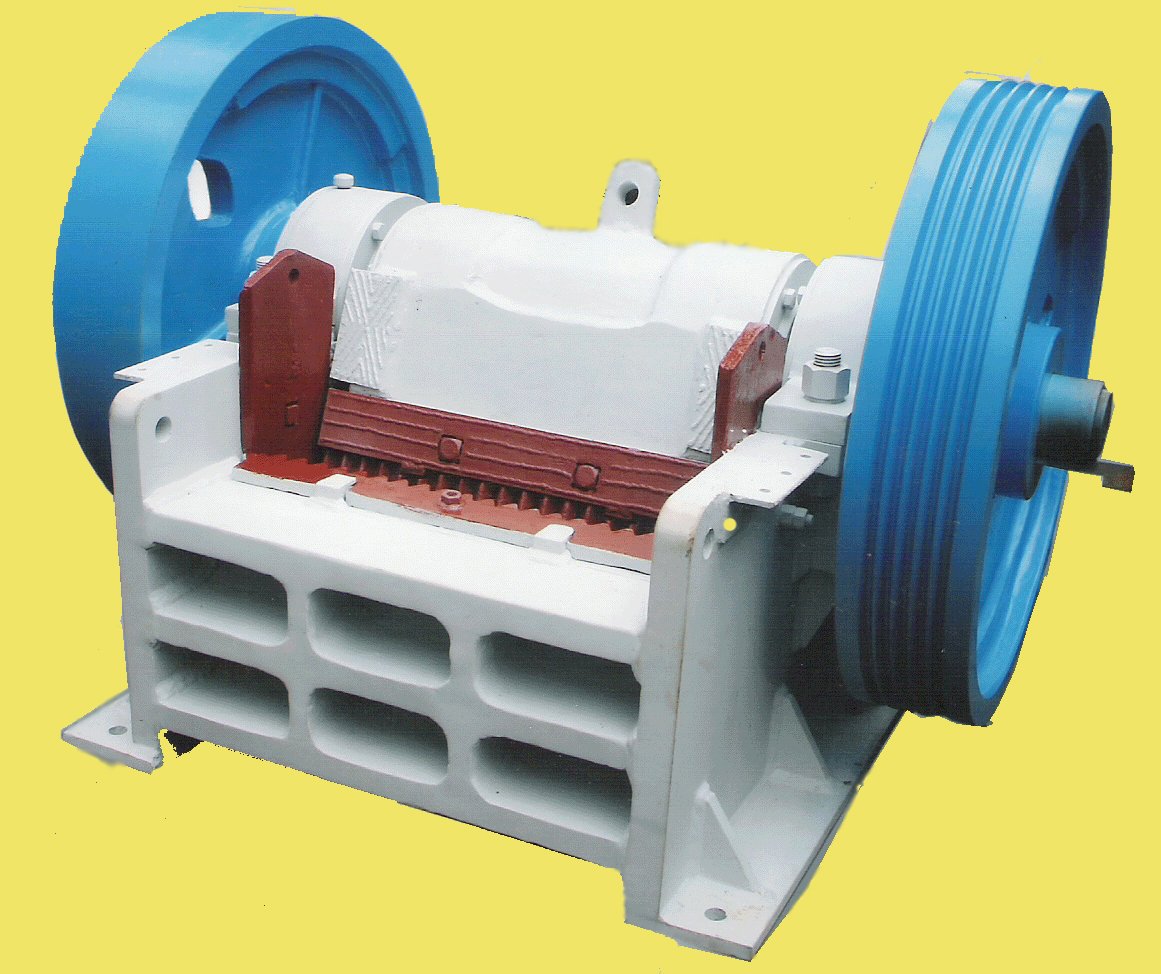

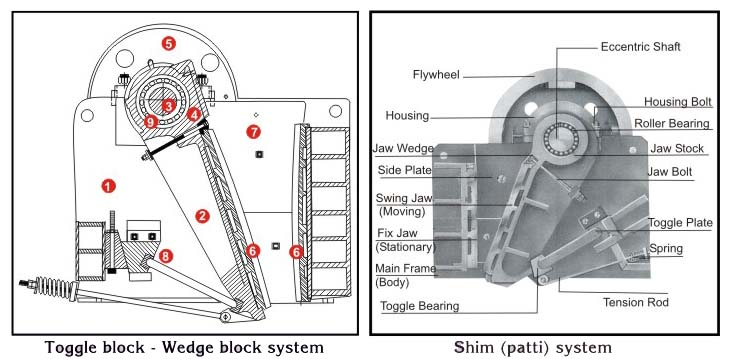

DIAMOND is a trusted and reliable brand for its high quality and good manufacturing. It specializes in producing Jaw Crusher which is widely used in mining, quarry, material handling. The company has been a manufacturer and exporter of the crushers for decades. Over these years, company has gathered specialists and experience in designing and manufacturing various models of Jaw Crushers. By constant research, our engineers have been able to develop machines that have good performance and easy maintenance. The structure of Jaw Crusher includes Main Frame, Main shaft, Roller Bearings, Eccentric Shaft, Jaw Plates, Side Plates, Toggle Mechanism, Fly Wheels and Springs.

The series of our Jaw crusher include various models which can meet most capacity requirements in primary and secondary crushing, at the same time, with low power consumption and easy maintenance. Every feature of these machines has been carefully designed to provide superior quality and performance. The high capacity of this machine can be ensured by the large feed opening and force-feeding action from the inward and downward eccentric movement of the swing jaw. The jaw has a smaller discharge setting, allowing for a higher degree of flexibility with relative equipment. The machine is easy to install and debug. They are widely applied in areas of mining, metallurgical, construction, smelting, hydraulic and chemical industries, etc and widely used for crushing various materials like stone, granite, trap rock, coke, coal, manganese ore, iron ore, emery, fused aluminum, oxide, fused calcium carbide, lime stone, quartzite, alloys, etc. These crushers are recommended by leading consultants in this field and are used by hundreds of customers all over the world.

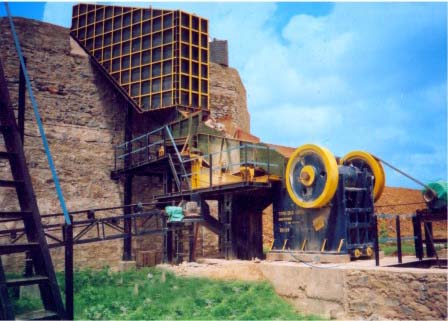

Primary Jaw Crusher

Secondary Jaw Crusher

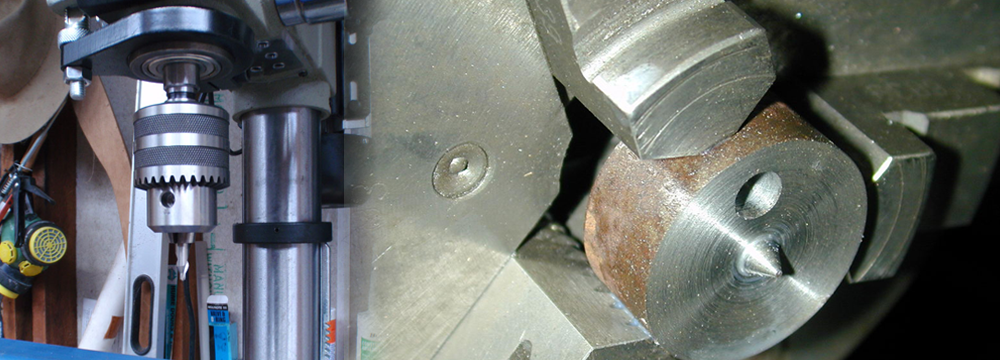

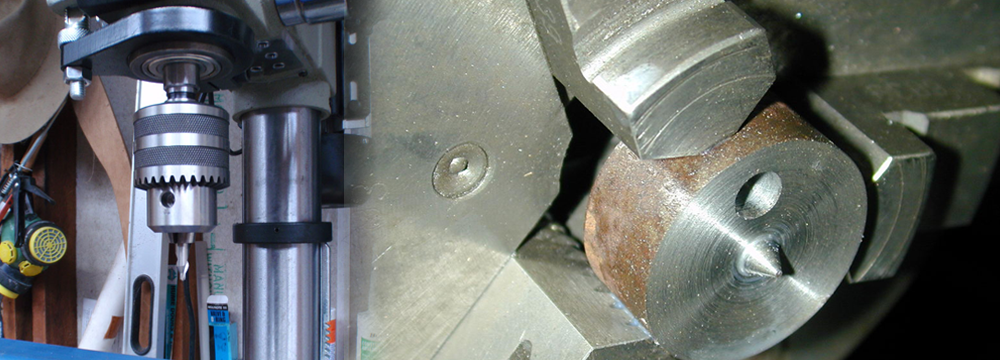

Cone Crushers are used for crushing of medium-hard to extremely hard, tenacious and brittle products demanding a final grain with a high cubic grain proportion. The lower part of the housing includes the hydraulic piston for gap adjustment, the upper section accommodates the crushing cone. Crushing of the feed material is effected between the eccentrically rotating crushing cone and the fixed crushing shell. Throughput capacity is up to 250 tph, crushing ratio is up to 1:8.

Feed materials: granite, basalt, diabase, hard rock, limestone, different types of ore, slag.

Cone Crusher

Drive System

Crushing Cone

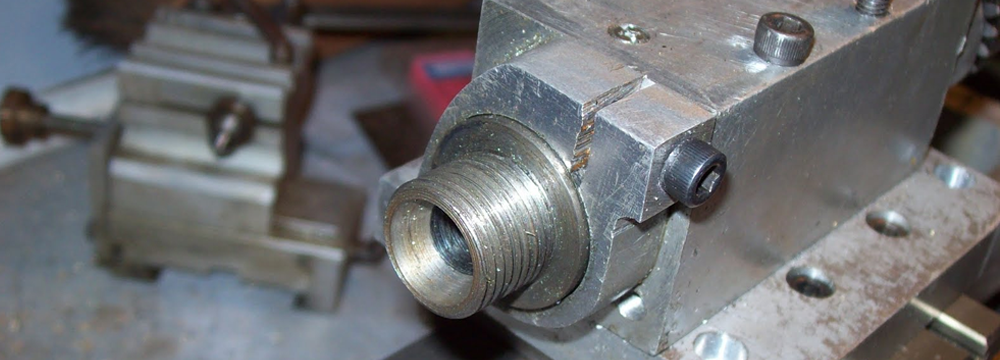

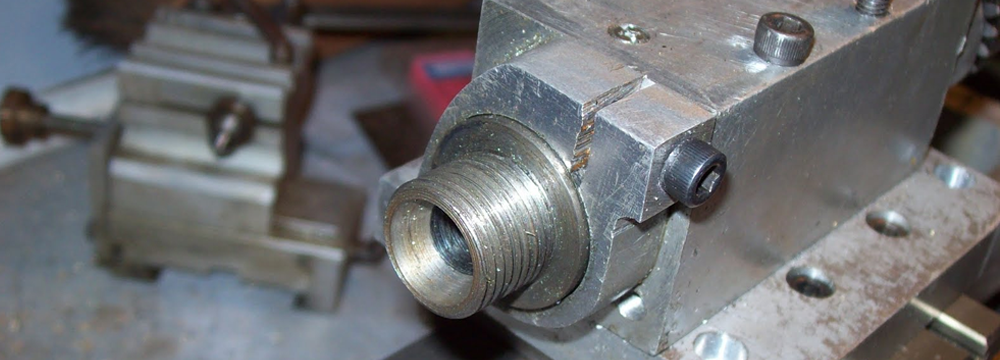

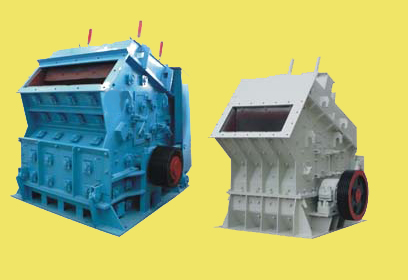

Diamond offers several models of high-quality impact crushers which are used in both primary and secondary crushing of aggregate, and in recycle crushing of reinforced concrete, asphalt and other construction and demolition debris. Diamond impact crusher is a new design that produces an excellent cubical product. This impact crusher produces a high ratio of reduction. The impact crusher is built for durability and simplicity of operation. Adjustment is easy from the exterior of the crusher. Maintenance is simple through inspection doors, and electric power unit is standard. Diamond impact crushers offer greater reliability, higher production and are ideal for portable mounting.This series are optimized after adopting advanced techniques. It can crush granite, basalt, bluestone, etc, the diameters of which are from 100mm to 500mm, and its crushing compression strength is not more than 320Mp. The final product is desirable device (material) for aggregation used in highway and railway surface and water and electricity industry.

Horizontal Shaft Impactor

Diamond Tertiary Crusher Machine for:

Features :

Working Principle:

The mechanism involved is very simple. The rock to be crushed is fed through the hopper and a feed tube onto the center of a closed rotor.The rotor spinning at high speed throws the material with a great centrifugal force. When the accelerated rock hits the stationery rock-box, known as rock-on-rock principle, it breaks by impact along the natural fault lines resulting in a cubical shaped product which falls freely by gravity on to a conveyer belt below.

The rock-on-rock principle simulates the nature's way of impact and grinding that occurs in generation of particle shape in natural sand.

The Diamond crusher thus comes out a winner as producer of quality aggregates as well as Manufactured Sand, which is very close to the natural sand in particle shape and gradation.

Information Required for Diamond Selection:

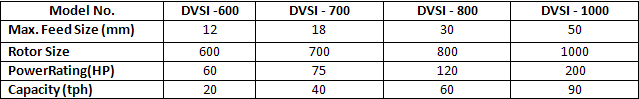

SPECIFICATIONS:

Vertical Shaft Impactor

Features:

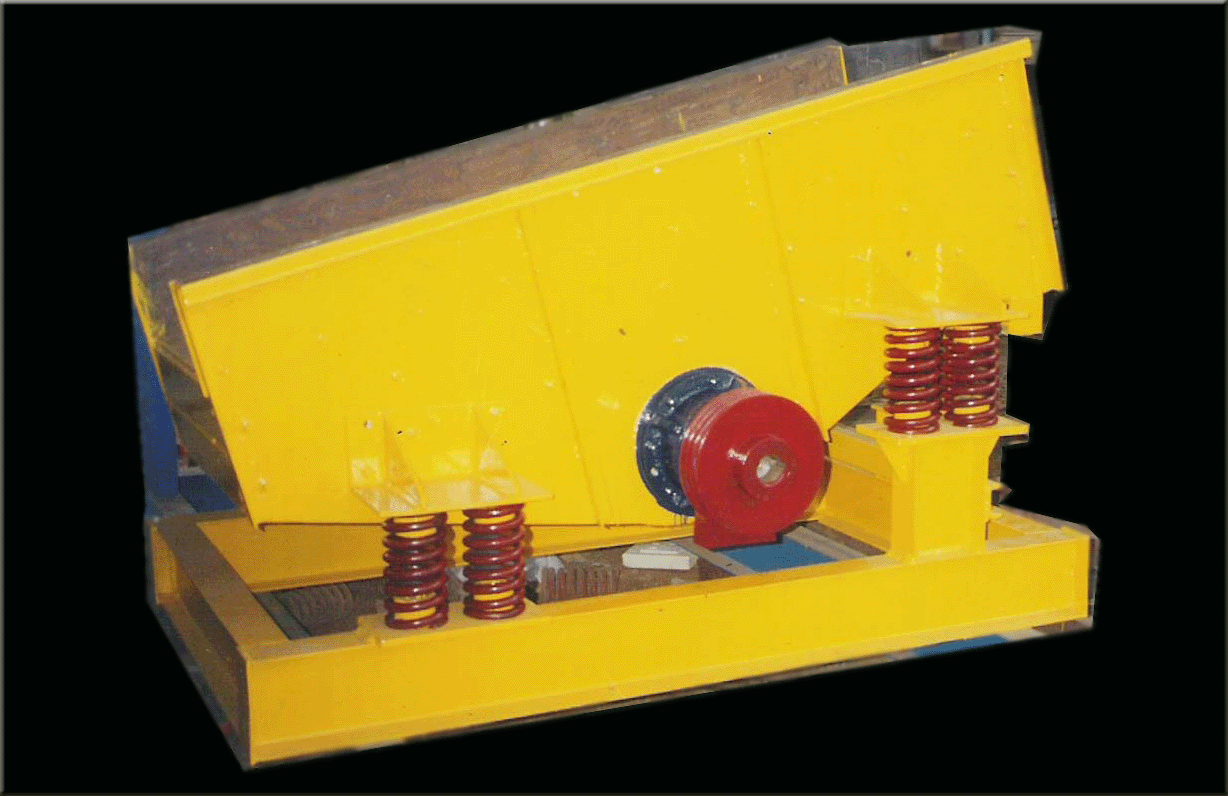

Diamond Vibrating Screens are engineered for heavy-duty and continous operation, and are built using modern material technology and impeccable quality.They are designed to be modular, robust and compact screening machines with exceptional performance for a wide range of materials - crushed stones, mining, recycling and process classifications.

Circular or elliptical stroke vibrator machanism can be adopted for coarse or fine screening of all mineral ores and hard stones.A high degree of screening efficiency is guaranteed.

Diamond Vibrating Screens provides a long service life, excellent adaptability and economical screening solutions under the harsh and rigorous mining & quarry conditions.

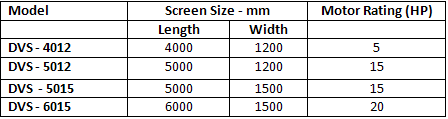

SPECIFICATIONS:

Vibrating Screens

Vibrating Feeders are unbalanced motor type shaft type are suitable for conveying of bulk raw material of all types and size to the crushers .The construction of the Vibrating Feeder is determined by the following factor that is application, size of raw material, bulk density and nature of raw materials. The Vibrating Feeder are manufactured upto a capacity of 250 tonnes/hours

Vibrating Feeder

TurnKey Aggregate Crushing System

TurnKey Aggregate Crushing System