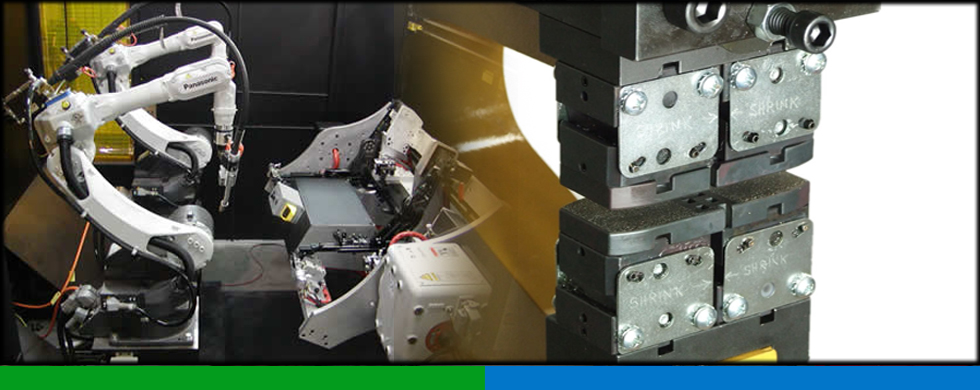

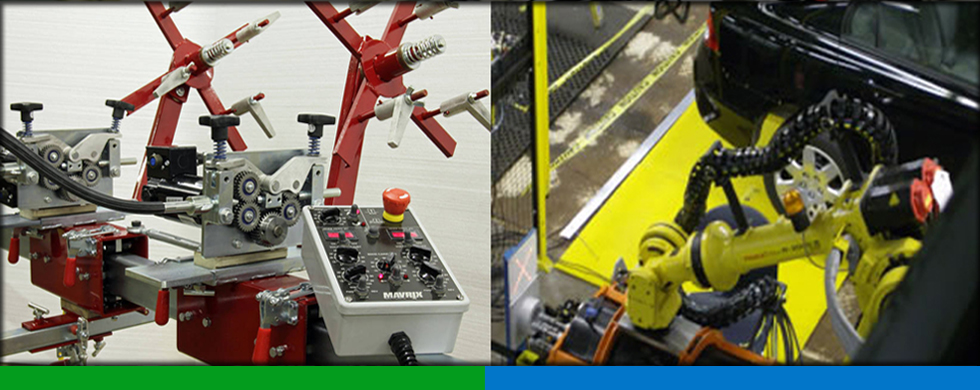

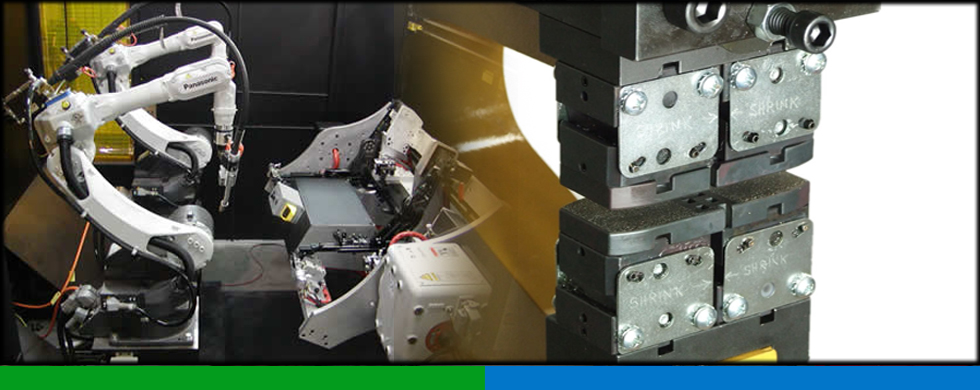

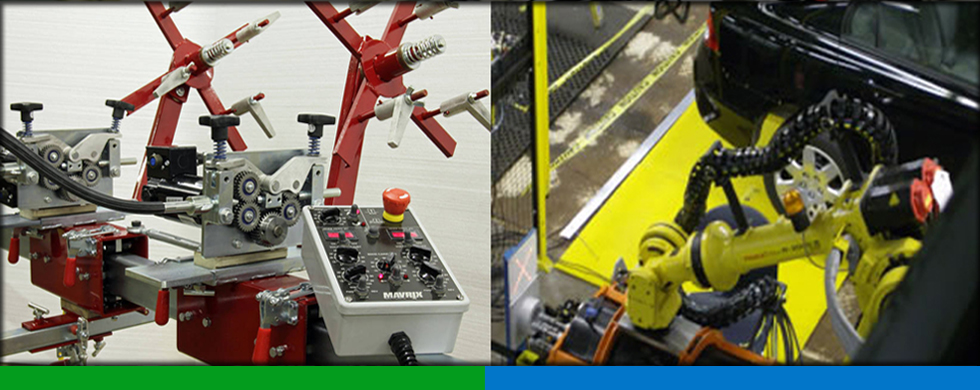

Tool Tech SPM was incepted in the year of 2001 as a manufacture and supply company providing various automated fabrication machines. Our range of product includes auto feed with parting, dry leak test with hyd pressing, fixture & guages, guages, hydraulic press with auto feed, sheet forming machine, leak testing machine, roll forming machines, dry leak testing machines, metal sheet roll forming, pick n place, pipe swaging & flerring, press tools, welding automation, welding SPM and multi spindle hydraulic press. All our products are highly efficient and conform to industry recommended quality standards. We have an integrated laboratory to conduct various checks and inspections on the developed products. In the region of Maharashtra, we are the only manufacturer of multi spindle baring presses. We possess various efficient machines that are handled by skilled machine operators, who form an integral part of our workforce.

With our qualitative products, we have acquired a large base of clients in the domestic arena. We are also in the progress of venturing into export markets and we aim to satisfy overseas clients in every aspect. Some of our valuable customers are enlisted below:

We do every effort to achieve utmost client satisfaction and consequently we offer service of customization and after sale support for our products. In our customizations service, we develop the product like sheet forming machine, leak testing machine, roll forming machines, industrial testing machines and package it according to the specifications of our clients. This gives them extra control over the products, ensuring better productivity for their businesses. We also provide quotations after the confirmation of technical specifications with our clients. If required, we can exhibit our machines and processes on client’s samples. Our commitment does not end on marketing the products, only. We provide effective after sales support which includes.

Developed by using various ferrous and non-ferrous materials, the range of our products include auto feed with parting, dry leak testing machine with hyd pressing, fixture & guages, guages, hydraulic press with auto feed, sheet forming machine, metal sheet roll forming, pick n place, pipe swaging & flerring, press tools, welding automation, welding SPM and multi spindle hydraulic press. All our products receive acknowledgement from our clients for its salient features of:

Industries Catered With our qualitative products, we cater to the demands of various industries such as automobile, process, printing & packaging and others.

Our state-of-the-art infrastructure includes a well furnished manufacturing unit and an in-house design unit. The production unit is spread over an area of 21,000 square feet, which also includes wide open green spaces. Production capacity of the unit is 300 units and it includes a number of latest make machines such as:

All the machines work 24x7 to develop the products according to industrial standards and specific designs provided by our design unit. This unit is well equipped with computers, based on innovative technology and running reliable CAD/CAM software.

Our company is one of the pioneering manufacturers that provide various fabrication machines. The products are ensured to be developed according to the latest market demands by using innovative techniques and processes. These are recommended by our research and development department that conducts researches on the new industrial developments and latest market demands. The department is well equipped with required machines and tools to efficiently conduct researches. The data collected from the researches is digitally stored and analysed for its feasibility according to our company’s entities and facilities. Only after the suggestions of the department, we implement the new technique and/or process in our product manufacturing. Software:-

Under the guidance and supervision of our owner Mr. Santosh Bhalshankar, we have developed a panel of experts. His huge experience of 15 years coupled with BE MECH degree has assisted us in employing qualified and talented personnel in our company. Our panel of experts are divided into different teams which include quality team, administrative team, sales team, agents, production team and others. All the teams work in coordination with each other to ensure maximum client satisfaction. Every personnel possess rich industrial experience in its definite field and they use it to fulfil specific demands of our clients.

We are committed to provide our clients, high performance and result oriented products that meet their quality expectations. For quality assurance of our products, we have an own laboratory which is equipped with various testing tools, equipments and accessories. This ensures that we deliver only the qualitative products to our clients. The received stock of raw materials is inspected at our premises and pre-inspected at its vendors’ premises. The entire production process undergoes under the strict vigil of our team of quality inspectors. Manufactured products are also quality tested on different parameters which includes tolerance, tensile strength, durability and other technical specifications.