• JIT Delivery: NO inventory carrying cost

• NO development cost

• Already proven undercarriage in the Indian Market

• Service support

• Forward integration possible with Track Module Supply

• Protects spare-parts market.

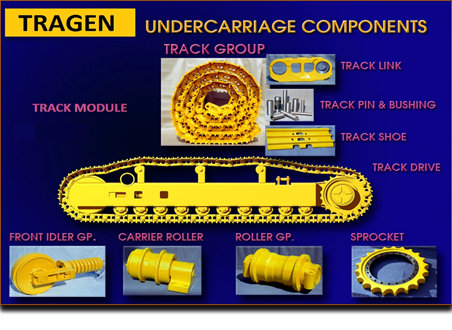

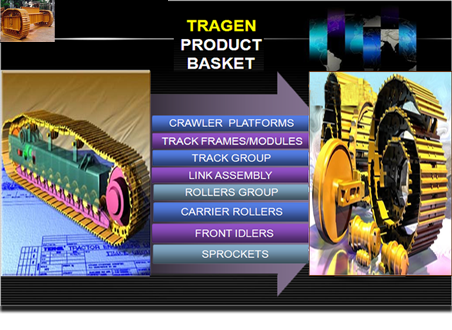

Based on the technology acquired from TENGL, TRAGEN proposes to manufacture & supply crawler undercarriage components for all major OEMs in India. Each component has a range of features that offers a wide range of benefits.

| Track Part | SALIENT FEATURE | BENEFITS |

| Sealed Tracks | • Cone-shaped Belleville Washers fitted back to back for effective sealing of link joints | • Outside dust, dirt cannot enter the bush and pin joint. Gives longer life of pin bushings compared to unsealed tracks. |

| Greased Tracks | • Special profile on bushing bore holds extra amount of

grease compared to plain bore of bushings in sealed track. • The compressible polyurethane dust seals offer effective sealing. They lock the grease inside and dust remains out. |

• The lubricated pin & bushing joint means lesser friction, better life. • Silent operation without any squeaking & scratching noises. |

| Links | • Optimized profile

• Generous radii in forgings • Smooth blending of different contours • Beefed up links available for heavy duty application |

Better strength in high operating stress areas • Ideal distribution of mass • Muscular link outlasts old link design |

| Pins & Master Pins | • Made out of deep hardening Boron steel heat treated with a

special cycle • Choice of master pin of plain round or 'T' type headed design available |

• The most optimal combination of hardened wear resisting case & toughened

impact resisting core. • Better selection option. 'T' design is maintenance-friendly. For marginal applications, regular master pin prevents weakening of pin boss |

| Bushings & Master Bushings | • Choice of two distinctly different methods of manufacturing available for different end applications. | For normal operation, a cost effective single stage heat treatment process is

deployed. • For demanding applications where track tension is high, a unique three stage Heat Treatment Process is used which enhances wear life. |

| Shoes | • Specially controlled chemistry during rolling • Unique press quenching process • Wide choice of number of grousers & shoe widths |

Gives the best combination of hardness & toughness. • No interference while flexing. • For different applications, the most appropriate selection is possible, without any compromise on number of grousers or strength. |

| Rollers | • Made from deep hardening steel • Subjected to special heat treatment • The oil plug is located on side • Endcollars are shrouded by roller flanges |

Optimum combination of wear resistance as well as impact resistance. • Easyserviceability • No accidental damage or breakage of End Collars in operation. |

| Idlers | • Multiple choice in terms of design - Spoketype,

Single Web type, Box type • Raw material composition |

Appropriate selection possible to suit the load pattern in actual field conditions. • Forged design with intrinsic high strength ensures favourable diameter to weight ratio. • Cast design is sturdier than fabricated design. |

| Sprockets | • A unique induction hardening process gives the best heat

treat profile on teeth. • Both ring type and segment type available. Also available with matching final drive for new/virgin applications |

• Long lasting sprocket without any tooth breakage problem. • Better selection for system design. • System supply. |