Superconditioning of Industrial Components - Cost Effective Wear Protection in Power, Cement, Steel And Mining Industries.

Thereis growing awareness to conserv vital machinery components of Steel, Cement, Power and Mining Industry, in view of fast depleting natural resources. With less than 10-15% weight loss, industrial components are rendered unusable and scrapped on account of wear & tear. These components are repaired/ reclaimed and reused in industry to achieve 100-200% performance at negligible cost as compared to the cost of original components.

Duraweld Offers Reclamation Services For

1. Coal Mill / Raw Mill Grinding Rolls, Table Liners in Cement & Mining Industries.

2. High Pressure Roller Press Roll in Cement Industries.

3. By Metallic Grinding Rolls of Thermal Power Plants.

4. Top/Bottom Pinch Rolls, Wrapper Rolls and Concast Rolls in Steel Industries.

The Satisfaction of our customer is the testimony of Quality Standards achieved by us.

Weld deposition is very fast and weld deposition per welding head is in the range of 100-120 kgs. per day.

Duraweld have state of art Robotic Microprocessor based Welding Systems to undertake Superconditioning of Raw mill Rolls/ Table Liners, High Pressure Roller Press Rolls etc.at its work and INSITU at sites.

Steel Industry

Wrapper Rolls

Wrapper Rolls Top Pinch RollAfter Welding

Top Pinch RollAfter Welding Top Pinch Roll After Machinings

Top Pinch Roll After MachiningsCement Industry

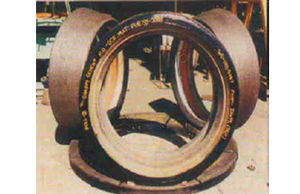

Reclaimed Grinding Tyre Of Pfeiffer Mill

Reclaimed Grinding Tyre Of Pfeiffer Mill Liische RM Tyres LM - 50.6

Liische RM Tyres LM - 50.6 Coal Mill Table Liners & Tyre

Coal Mill Table Liners & Tyre A Set Of Ltjsche Mill Grinding Tyres & Table Liners

A Set Of Ltjsche Mill Grinding Tyres & Table Liners High Pressure Roller Press Roll

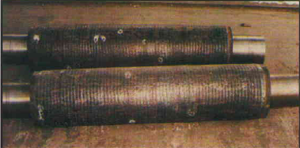

Before Reconditioning

High Pressure Roller Press Roll

Before Reconditioning High Pressure Roller Press Rol After Welding

High Pressure Roller Press Rol After WeldingConcast Rolls

The Wear and tear of these rolls is negligible, but the rolls are scrapped on account of pit initiation, stress cracking, thermal fatigue, fire cracking etc. Generally these rolls are of low Cr-Mo alloy forging. These rolls are repaired with suitable cladding material whicjh offers good weldabilly, easy machinability, maximum tempering resistance, resistance to thermal & thermo-mechanical fatigue, high thermal conductivity, low thermal expansion, high temperature oxidation resistance, resistance to corrosion cracking and corrosion fatigue and resistance to pitting and corrosion. The welding procedure designed by Duraweld does not call for pre-heat as well as post-heat treatment.