Weldcast Wearplates

Duraweld Composite Wearplates

Wearplate Technology was first introduced in our country by none other than DURAWELD in the year 1991.

The Wearplate Technology

Wearplate manufacturing is the highly specialized process where in mild steel base plate is Weld Cast by simulataneous blending of alloy wires and alloy carbide constituents, which ensures maximum possible carbide concentration and minimum dilution. The Wearplate provides muscles on your metal/ machinery components to Combat wear very efficiently and econmically. the composite wearplates is weld cast by chronium and other mix Alloy Carbides to achieve properites Viz. Severe abrasion, moderate to heavy impact and heat resistance in one single plate without sacrificing very high initial hardness.

Wearplate manufacturing is the highly specialized process where in mild steel base plate is Weld Cast by simulataneous blending of alloy wires and alloy carbide constituents, which ensures maximum possible carbide concentration and minimum dilution. The Wearplate provides muscles on your metal/ machinery components to Combat wear very efficiently and econmically. the composite wearplates is weld cast by chronium and other mix Alloy Carbides to achieve properites Viz. Severe abrasion, moderate to heavy impact and heat resistance in one single plate without sacrificing very high initial hardness.

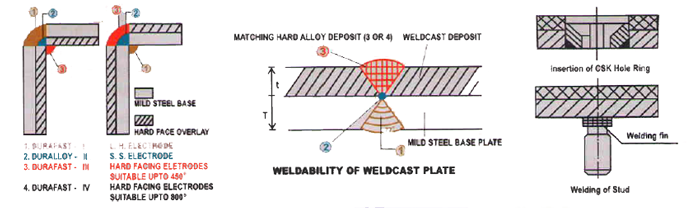

Fixing

DURAWELD WEARPLATES can be welded to any existing metal structure by welding the mildsteel base with low hydrogen or stainless steel electrode depending on the metal structure. Duraweld WEARPLATES are provided with countersunk holes or plug weld holes by a specially designed Metal Arc Disintegrator System. Studes are welded by stud welding machine on the mild steel base of DURAWELD WEARPLATES.

Appearance

The wear resisting side of Duraweld Wearplate appear as 65mm, smooth wide weld bands. These bands are fused together to form essentially a flat, even, continous ripple free surface. Due to the hard characteristic of the carbide layer and the contraction stresses, during the manufacturing welding process, cracks develop at the right angles to the surface but donot penetrate beyond the carbide layer.

Extreme Abrasion/ Impact Resistance

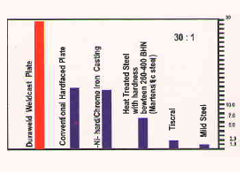

Duraweld wearpaltes, own its abrasion Resistance to Chronium Carbides/ Alloy Carbides Concentration of 45% to 60% in weld cast deposite and impact Resistance to Ductile Mildsteel Base. High Carbide Concentration is due to ROBOTIC Weld Cast process which ensures very low dilution levels.

Cutting and Forming

DURAWELD WEARPLATES are usually cut by air plasma<, argon/ nitrogen plama cutting machines. They can be cut with gouging/ cutting electrodes or by carbon arc. The quality of cut on DURAWELD WEARPLATES is best with plasma equipment.

DURAWELD WEARPLATES can be cld rolled for large diameters or formed by way of brake press for smaller diameters.

/p>

MINIMUM BEND RADIUS

Hardface Outside : R 1000mm. Hardface Inside : R 150mm

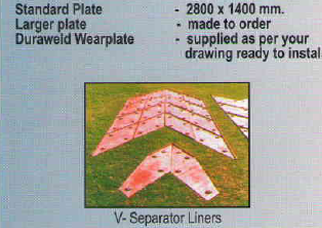

Size and Grade Selection

| Thickness | |||

| Overlay | Base | Total | weight Kg. per square Meter |

| mm | mm | + - mm | |

| 4 | 6 | 10 | 81 |

| 6 | 6 | 12 | 95 |

| 7 | 8 | 15 | 122 |

| 7 | 10 | 17 | 132 |

| 9 | 10 | 19 | 144 |

| 9 | 12 | 21 | 160 |

| 6+6 | 12 | 18 | 140 |

| 6 | 25 | 31 | 238 |

| Grade | Typical Properites |

| DW-standard Alloy | HIgh Stress abrasion and heavy impact use upto 450degree C. Plate can be rolled to 150 mm. Radius Hyper eutectic structure of hard M23 C6 &M7C3 carbide in the matrix of eutectic carbides and martensite. Matrix hardness more than 700 VHN, carbide hardness more than 800 to 1600 VHN. |

| DW_FW ALLOY | High Stress abrasion and heavy impact use upto 550degree C. Plate can be rolled to 150 mm. Radius Hyper eutectic structure of hard M23 C6 & M7C3 carbide in the matrix of eutectic carbides and martensite. Matrix hardness more than 700 VHN, carbide hardness more than 800 to 1600 VHN. |

| DW-HT Alloy(a) | High Stress abrasion at elevated temperature upto 800degree C. Austenitic matrix with complex carbide of M23 C6 & M7 C3 type of Cr. MO. V. W,NB. Matrix Hardness 660-700 VHN Carbide Hardness - more than 1600 VHN. |

| DW-HT Alloy(b) | High Stress abrasion at elevated temperature upto 550degree C. Austenitic matrix with complex carbide of M23 C6 & M7 C3 type of Cr. MO. V. W,NB. Matrix Hardness 660-700 VHN Carbide Hardness - more than 1600 VHN. |