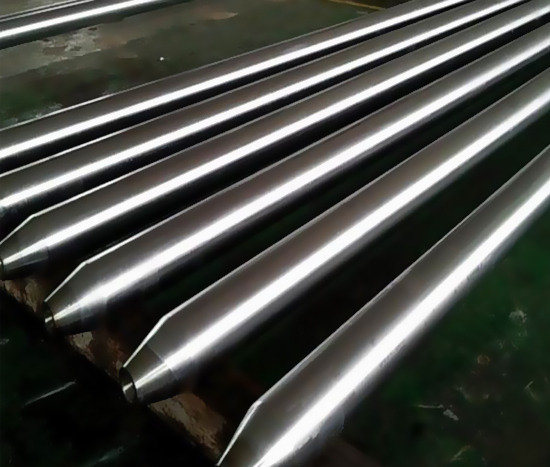

Rod ( Forged & Machined)

Over the past few years,automotive forging manufacturing technology is in the continuous improvement.Today,what takes a leading role in the market is the low cost,high strength anf tight tolerance.In drop forging production process,the strict requirements for forgings are just as important as to the requirements of the finished product.Drop forging companies around the word constantly look for a better production method to achieve the objectives and requirements of the auto parts buyers.

The offered product is designed and developed by our qualified professionals using premium quality factor inputs that are sourced from our trustworthy vendors. Our products are appreciated and accepted in domestic markets for its diverse and unique features. This range can be obtained from us within stipulated time-frame with assured quality.

Process: Collar Cold Forging and machining

Cold forging is a manufacturing process where a bar stock is inserted into a die and squeezed with a second closed die. The deformation starts at room temperature and changes the shape and size of the initial part until it has assumed the shape of the die. At this final step, the part can reach a temperature of up to 250 degree celcius, since the friction strain rates are very high during deformation.

The process requires high-resistance dies and high-duty steel, usually reinforced by retaining rings. Even if these dies are quite expansive compared to hot forging dies, their life time is much higher, leading to a competitive cost per unit. However, this can only be achieved with a suited design and efficient forging process, thanks to excellent engineering skills.

- High Performance

- Less storage space

- Higher geometric precision and stable quality

- Better durability and improved metallic structure

- Better surface finishing

- Safer production due to the automation process

Benefits

This is a highly automated manufacturing process and parts can be made economically. Another benefit of cold forging is the lack of grain growth and therefore perfectly aligned to the shape of the part metal grains with an exceptionally strong and resistant surface.