Facilities

Introduction : Equatorial Engineering Pvt. Ltd., is involved in manufacture of machined castings. The primary purpose for creating the facility was to produce Hardenable and Chilled Iron Lifter Bodies (Tappets) for the international market.

The plant covers an area of 22,000 sq. ft of land and 18,000 sq. ft. of buildings. The company has qualified and experienced officers and work force that are thoroughly knowledgeable about the metallurgical and metrological requirements of the products manufactured by the company.

The company gets the hardening of tappets done at an approved Heat Treater located near Pune. The company has its own quality assurance team located at the approved Heat Treater.

The company has manufactured and exported over 10,000,000 Tappets till date, meeting specifications of all major American automotive OEMs.

Products : Fully Machined Hardenable Iron, Chilled Iron and Ductile Iron Castings such as Tappets, Hubs, Split Bearings etc. Valve Lifter Components, Throttle Bodies, Ring Type Joints.

Production Equipment

Foundry

Furnace

- 500 kg capacity medium frequency induction furnace: 1 no.

- Pneumatic moulding machines: 2 nos.

- Sand mixer: 1 no.

- Shot blasting machine: 1 no.

- Electric annealing furnace: 1 no.

- Corresponding auxiliary equipment.

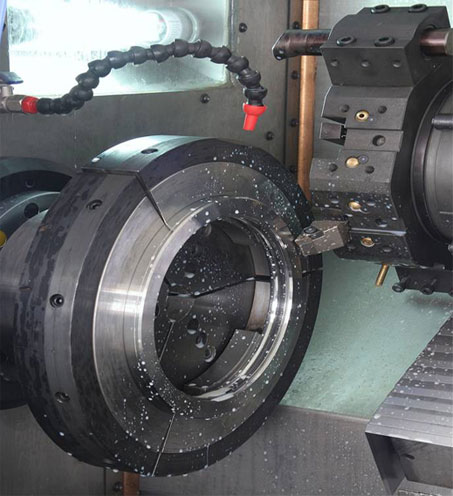

Machine Shop

Automats

- Centreless Grinders: 3 nos.

- Lathes: 7 nos.

- Automats: 12 nos.

- Crown grinder: 1 no.

- ID grinder: 3 nos.

- CNC lathes: 2 nos.

- Tool grinder: 1 no.

Quality Assurance Equipment

Foundry

Foundry

Sand testing equipment: 1 set. Microstructure specimen preparation equipment 1 set. Microscope with computer interface for storing images: 1 no. Eddy Current microstructure comparator for verifying carbides.

Machine Shop

CNC Machining

- Surface plate: 1 no.

- Profile projector: 1 no.

- Verniers: 6 nos.

- Surface finish tester: 1 no.

- Gauges for inspecting tappets.

- Hardness testing machines: 2 nos.

- Digital micrometer: 1 no.

Quality Certifications

Hardness tester

Standards Room

ISO 9001:2000

American Petroleum Institute (API) 6A

Production Capacity

Foundry

Heat Treatment Furnace

200 tonnes of net good castings per month.

Annealing

600,000 tappets per month. 4,500 hubs per month.

Machine Shop

500,000 tappets per month. 4,500 hubs per month. 6,000 Ring Type Joints per month.