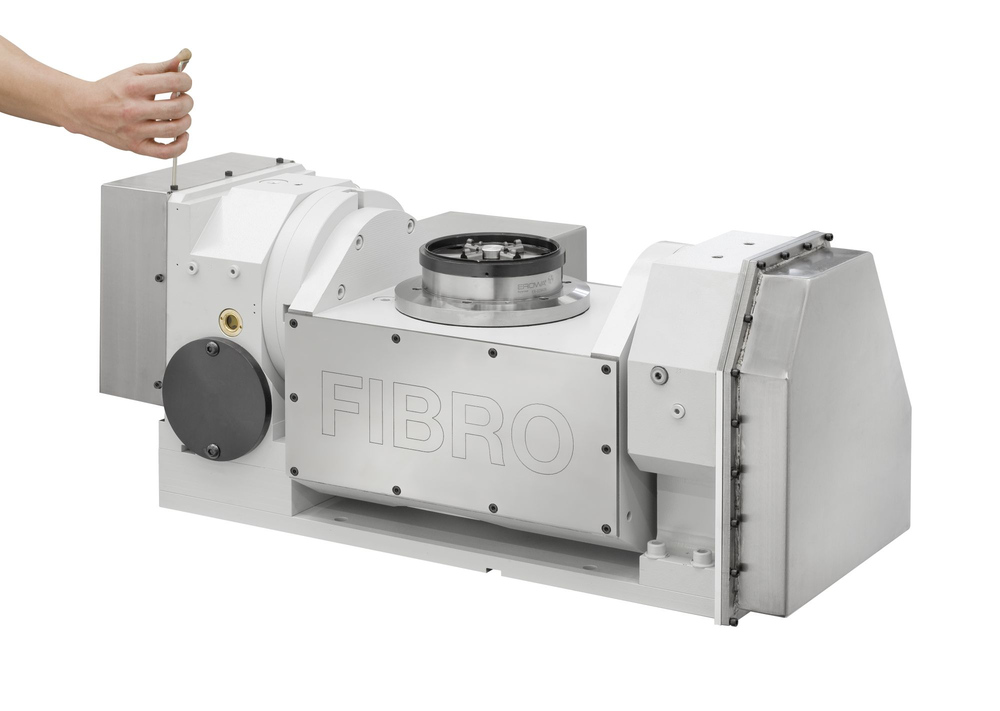

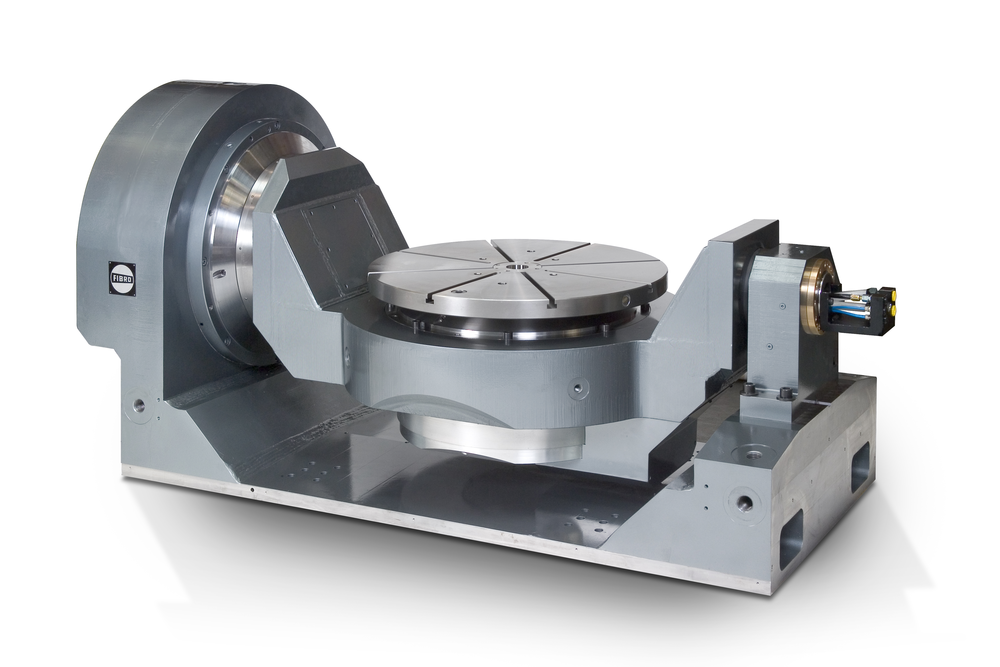

FIBROPLAN® NC ROTARY TABLES

FIBROPLAN® NC rotary tables are equipped with a backlash-adjustable worm drive for use in machine tools for universal positioning. Rotary and multiple-axle machining (simultaneous operation) is possible. The application of high-resolution measuring systems and the special design features with high-precision, rigid bearings result in high positioning accuracy. Through hydraulic clamping in the positioned state, high machining forces can be absorbed. FIBROPLAN® NC rotary tables are available in different designs, configuration levels and variants. Multi-axle designs and combinations with linear tables, designs with pallet clamping devices and pallets as well as customised solutions are possible.

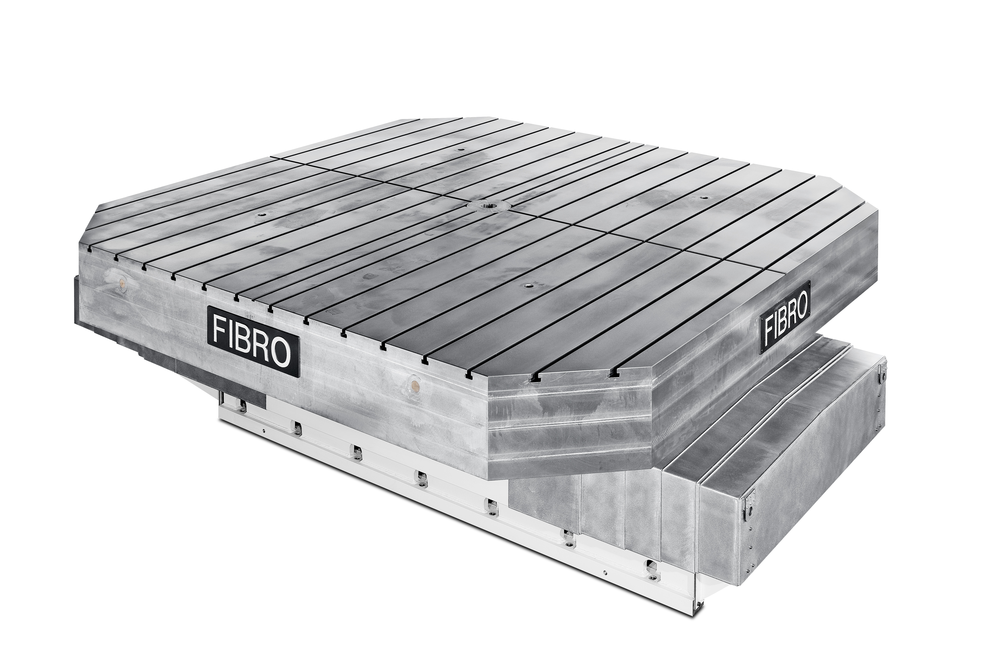

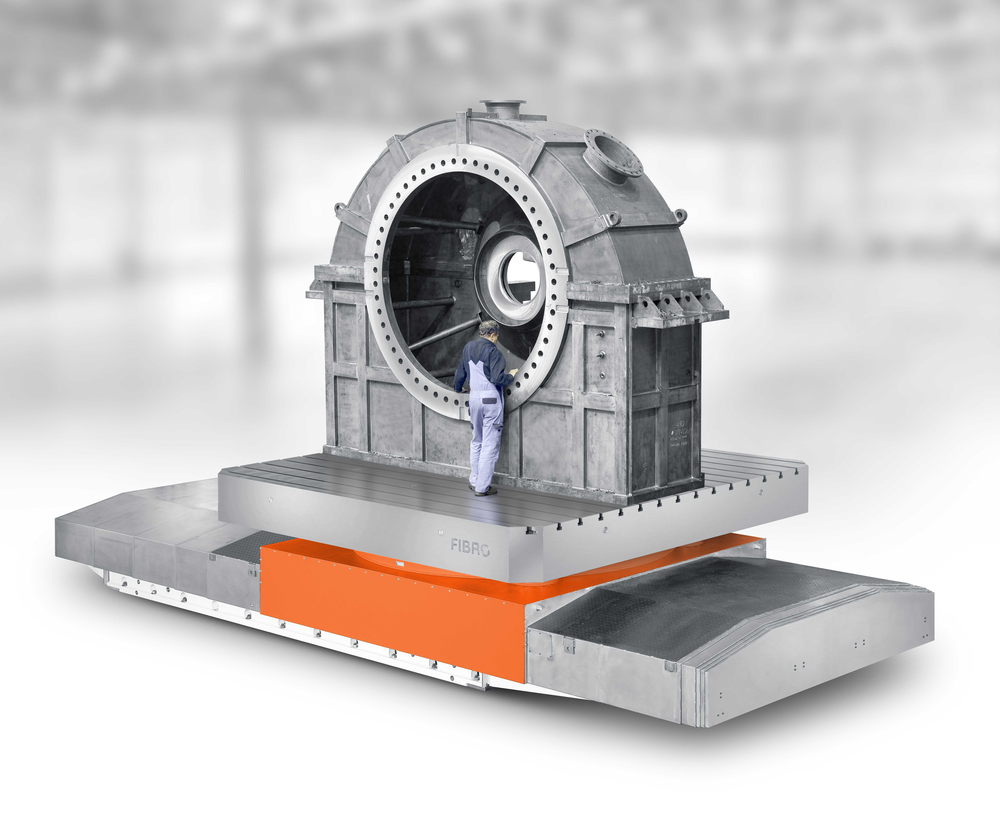

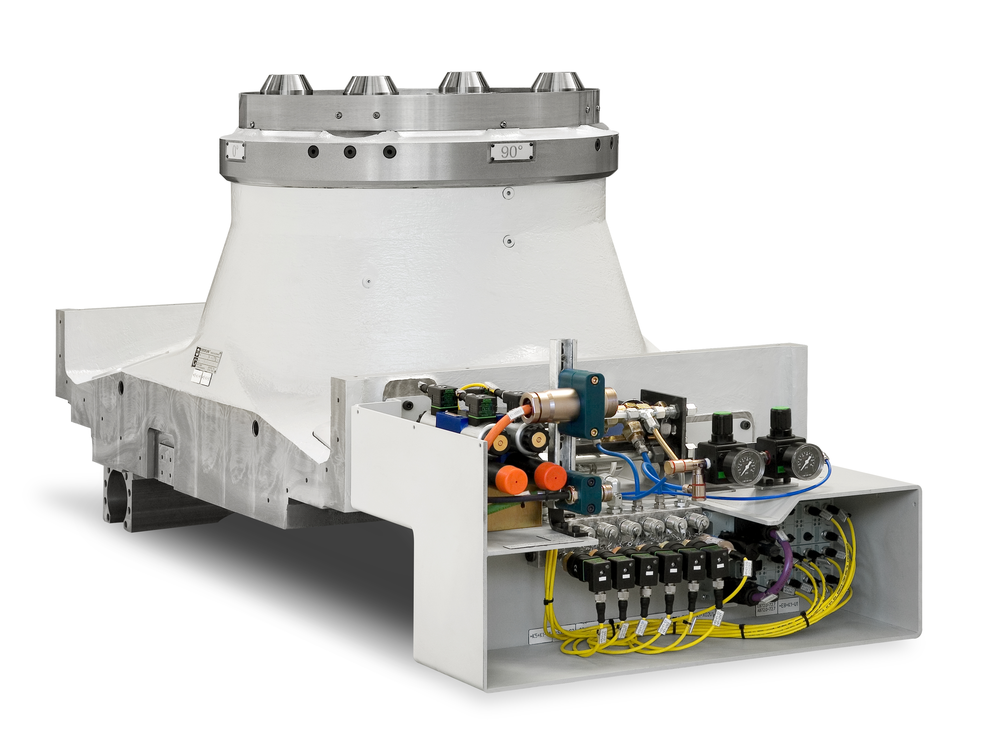

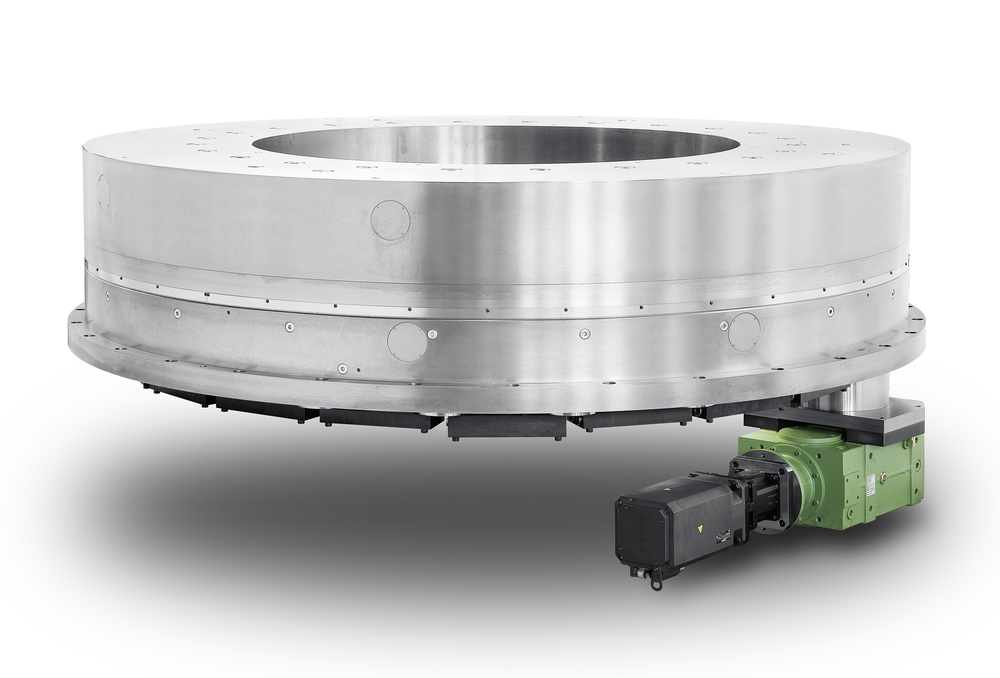

FIBROMAX® HEAVY-LOAD ROTARY TABLES AND HEAVY-LOAD ROTARY-LINEAR TABLES

FIBROMAX® NC rotary tables for universal positioning, rotary and multiple-axis machining (simultaneous operation). The modern conception with a rigid mechanical design, combined with high-quality drive and control elements, allows :

- Transported load over 400 tons

- Flexible positioning

- High repetitive accuracy

- High precision in terms of radial and axial concentricity in the micrometer range absorption of radial and axial forces through preloaded and generously dimensioned axial/radial bearing

- Hydraulic table top clamping for even higher tangential forces and offloading the gear

- Outstanding characteristics for rotary milling and simultaneous machining by preloaded bearings and electrically pre-stressed drive (twin drive).

- Operational safety and long service life as a result of careful design

- Low maintenance

- Wide variety of standard models – different types, configuration levels, and variants

- Overall system has been optimised in terms of rigidity

- Optimum power flow from the indexing table via the bearing through the roller circulation shoes and the linear table into the foundation

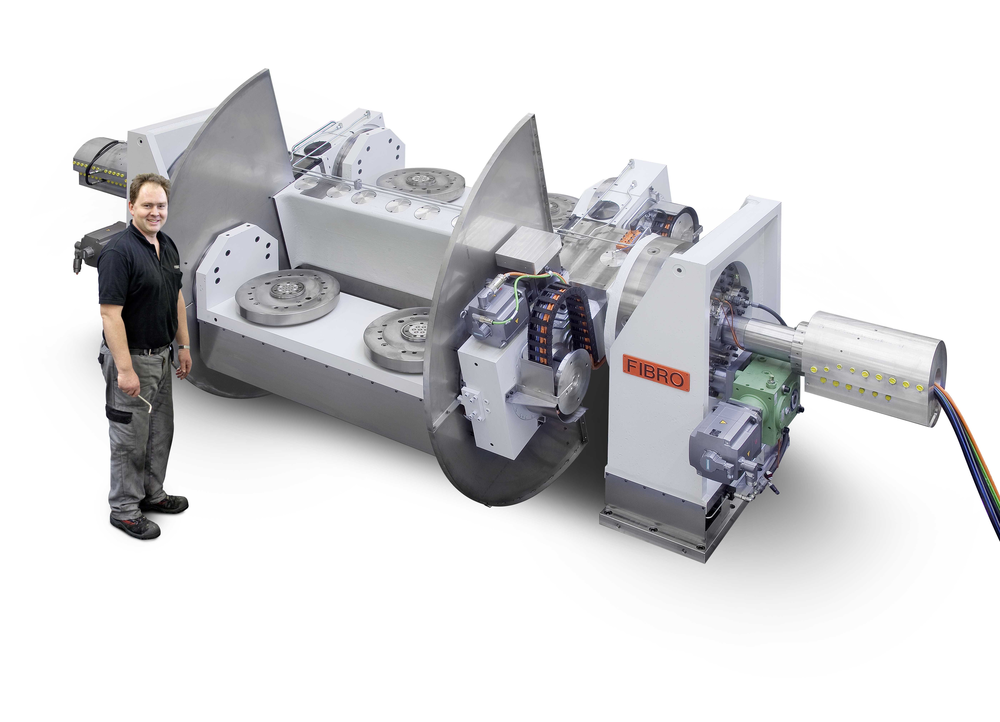

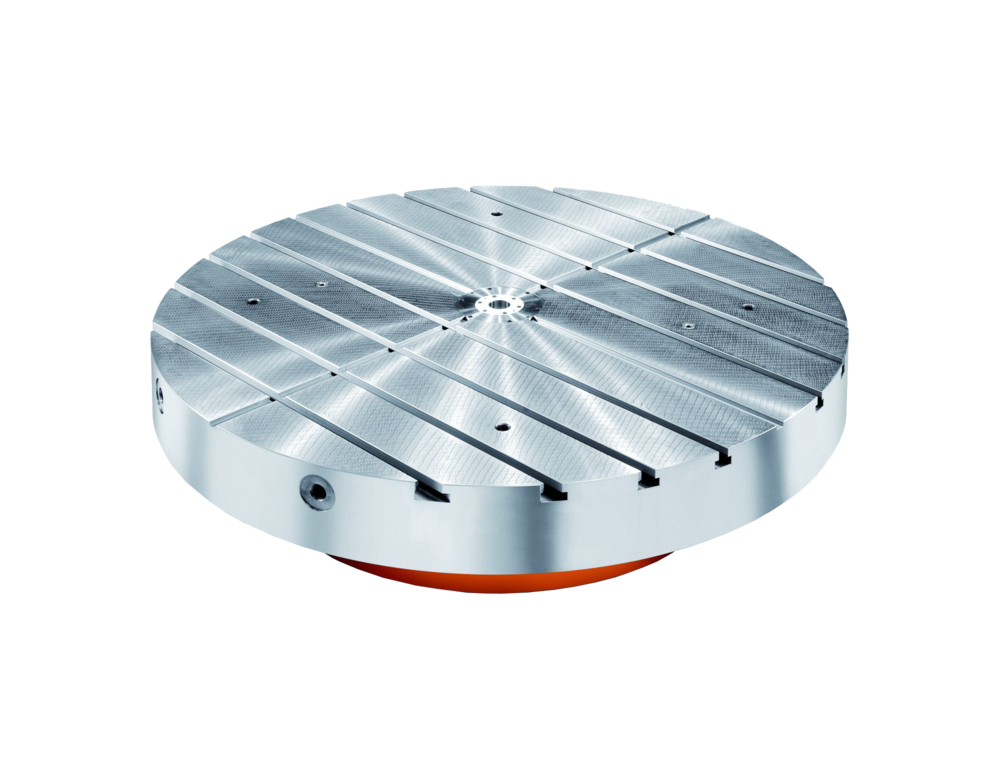

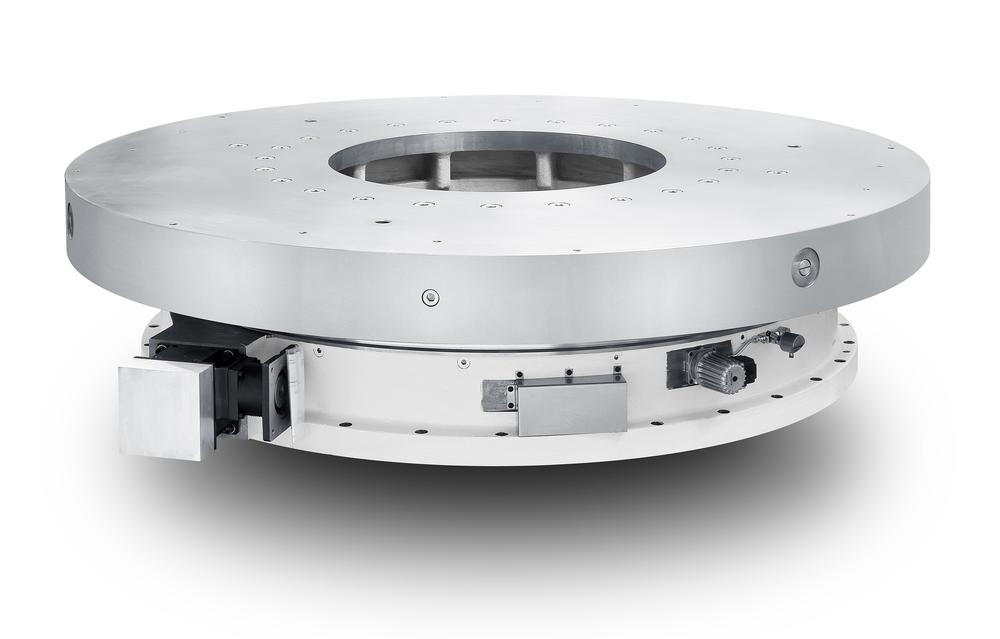

FIBRODYN® DA

Highly dynamic NC rotary tables with direct torque drive

The directly driven FIBRODYN NC rotary tables are designed for highly dynamic and high-precision turning and positioning tasks in machine tools and production systems. With extremely short switching times, they enable flexible positioning in freely selectable angular steps. FIBRODYN works completely without gear parts, which ensures zero backlash and thus high control quality. With the high-precision rotary tables, both very high and very low, uniform indexing table speeds are possible with a repeat accuracy of less than 0.2 angular seconds. The axial and radial runout accuracy of FIBRODYN is in the μ range. A hydraulic table top clamp connects the table top with the housing in a non-positive manner without any drive components protruding beyond the housing contour. This ensures particularly compact dimensions.

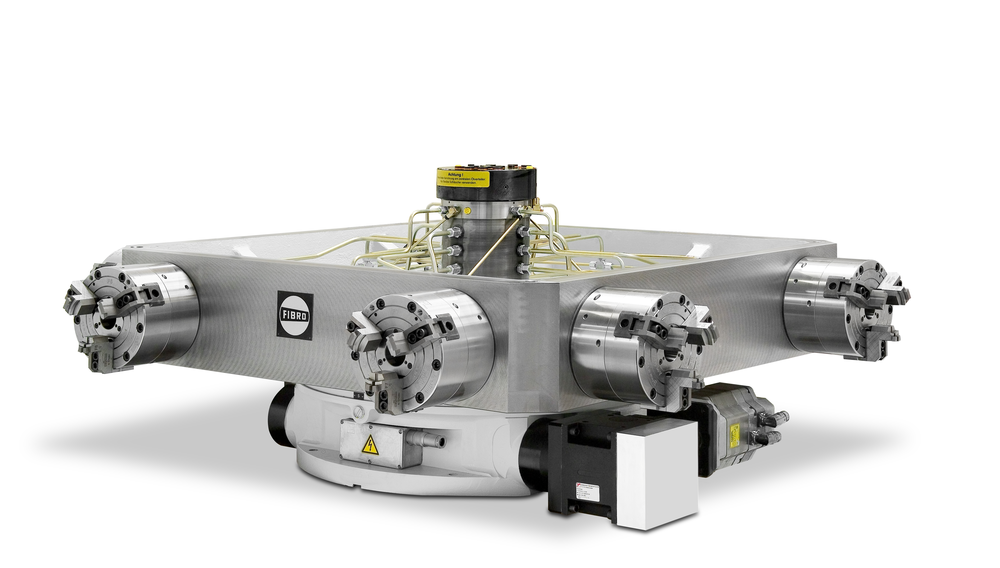

FIBROTAKT® STANDARD WITH FACE GEAR

FIBROTAKT® indexing tables have been developed for precision divisions and the absorption of high machining forces. Interlocking in the FIBRO face gear ensures continuous high precision and rigidity. Different versions and drive types ensure optimum device selection for the respective application. Even for heavy structures, the flush-mount rotary table FIBROTAKT® for rotary transfer machines combines minimum switching times with maximum precision and rigidity. It features a non-lifting indexing table, girth gear drive and easy access from below.