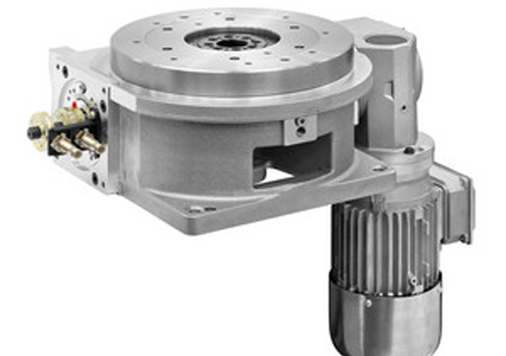

FIBROTOR® WITH CAM DRIVE

ELECTROMECHANICAL UNIVERSAL ROTARY TABLES An extremely long life time and shortest cycle time with an excellent precision and no need for maintenance - these are important aspects to any production line. FIBROTOR® rotary tables combine all of them and offer as an additional highlight up to five years warranty. Thanks to its completely new developed control cam, energy consumption drops by 20 %. Alternatively, higher masses can be moved, shorter indexing time can be realized or a smaller rotary table can be used. Indeed, FIBROTOR® rotary tables may be used as assembly tables; welding, positioning or storing tables; in packaging, printing, labelling or laser machines, as well as for light cutting. FIBROTOR® rotary tables work without elastic drive elements that tend to get worn out and enable highly precise positioning and repeatability. Extremely short positioning times ensure excellent productivity.

ELECTROMECHANICAL UNIVERSAL ROTARY TABLES

An extremely long life time and shortest cycle time with an excellent precision and no need for maintenance - these are important aspects to any production line. FIBROTOR® rotary tables combine all of them and offer as an additional highlight up to five years warranty. Thanks to its completely new developed control cam, energy consumption drops by 20 %. Alternatively, higher masses can be moved, shorter indexing time can be realized or a smaller rotary table can be used.

Indeed, FIBROTOR® rotary tables may be used as assembly tables; welding, positioning or storing tables; in packaging, printing, labelling or laser machines, as well as for light cutting. FIBROTOR® rotary tables work without elastic drive elements that tend to get worn out and enable highly precise positioning and repeatability. Extremely short positioning times ensure excellent productivity.

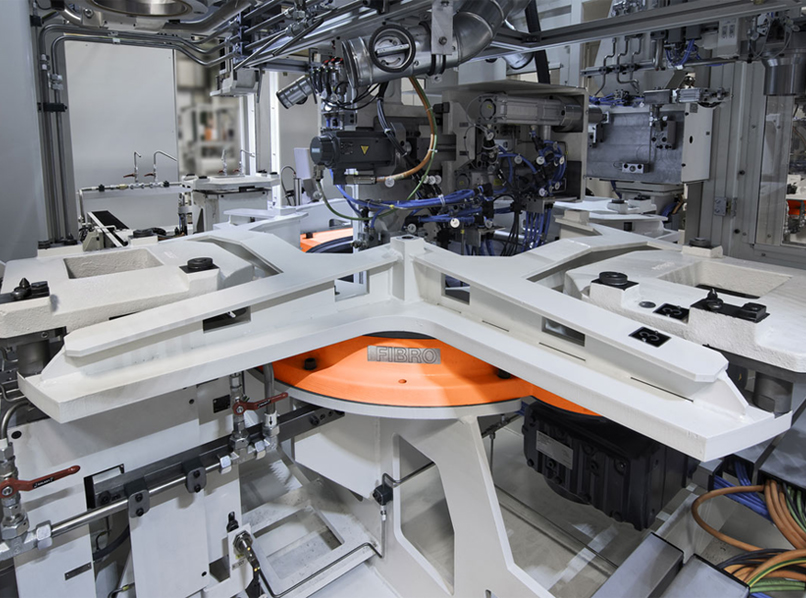

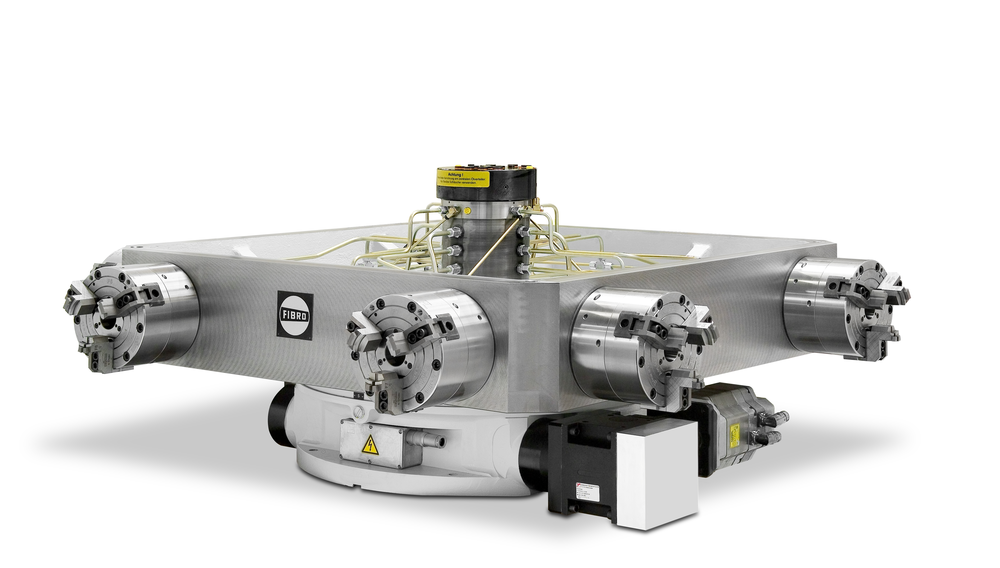

A vast range of products

FIBRO can offer you the suitable rotary table type for the application at hand, with the FIBROTOR® product range. FIBRO provides highly accurate solutions, specifically made to satisfy each customer's demands, from the FIBROTOR® EM line, or an attractively priced universal rotary table from the FIBROTOR® ER line, which serves as a great basic model and which can be supplied in short term thanks to a maximum degree of standardization. The rotary indexing ring FIBROTOR® RT is perfect for any application which requires a large center hole. For flexible positioning FIBROTOR® EM and FIBROTOR® RT are available as NC type. All FIBROTOR® rotary tables can be used horizontally and vertically.

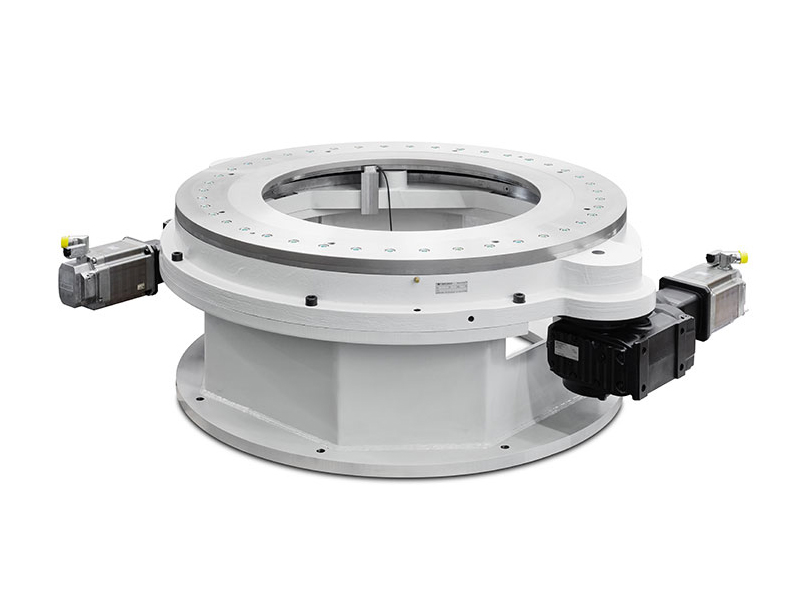

FIBROMAT®

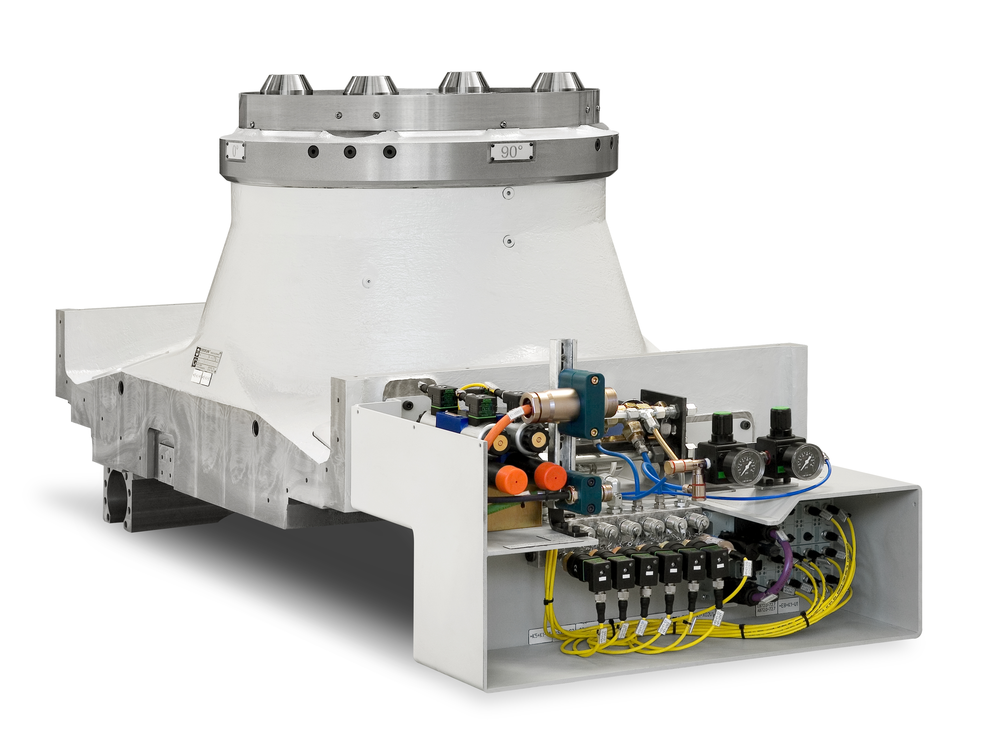

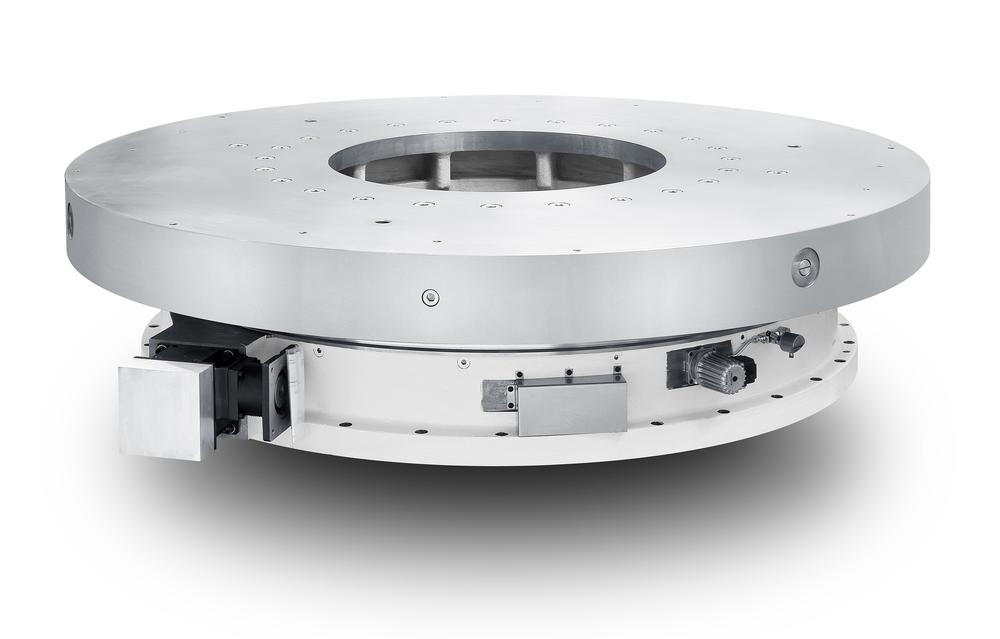

Heavy-Load Positioning Tables

A powerhouse with an extremely large center hole and very flat design at an optimum price — the FIBROMAT heavy-load positioning tables from FIBRO. When large and heavy fixtures have to be positioned dynamically and precisely, the FIBROMAT modular heavy-load positioning table is the optimum solution. It fits perfectly into automobile body in white, as the heart of work piece storages or in honing centers, for example. The maintenance-free rotary table with lifetime lubrication is driven by reliable spur gear drive.

Your application

- For the dynamic and precise positioning of large and heavy fixtures and parts

- For superstructural parts up to 9500 mm

- Ideal for shell and welded design applications

- Deployable as a setup station, large format pallet exchanger and for general handling tasks

- Available as an NC or indexing variant

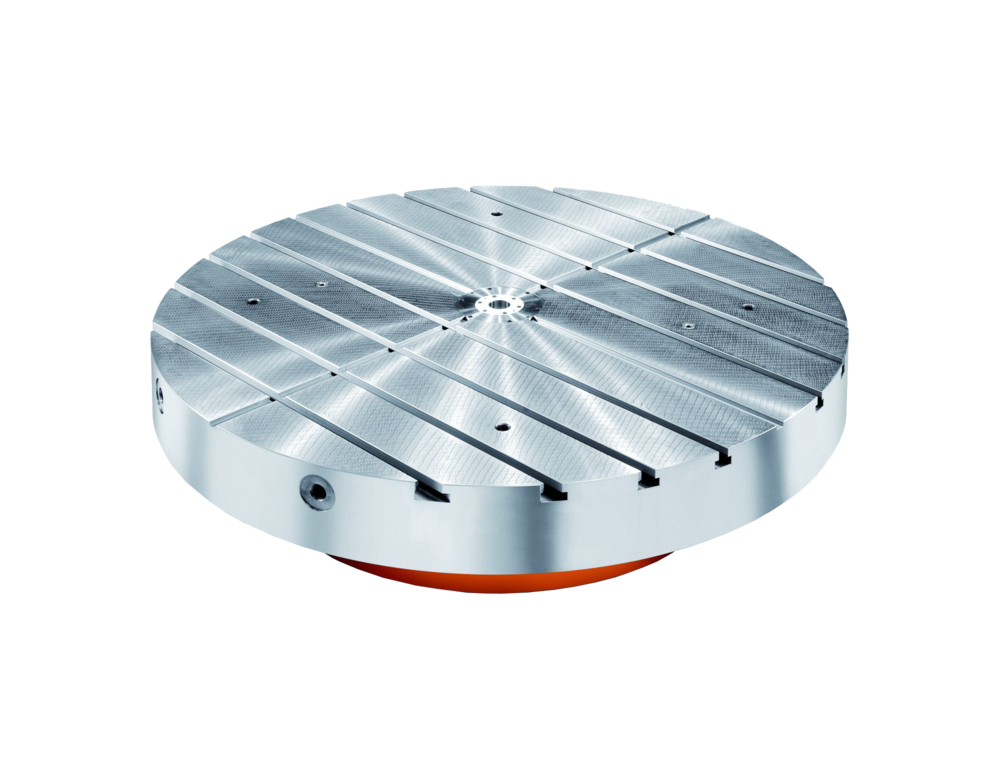

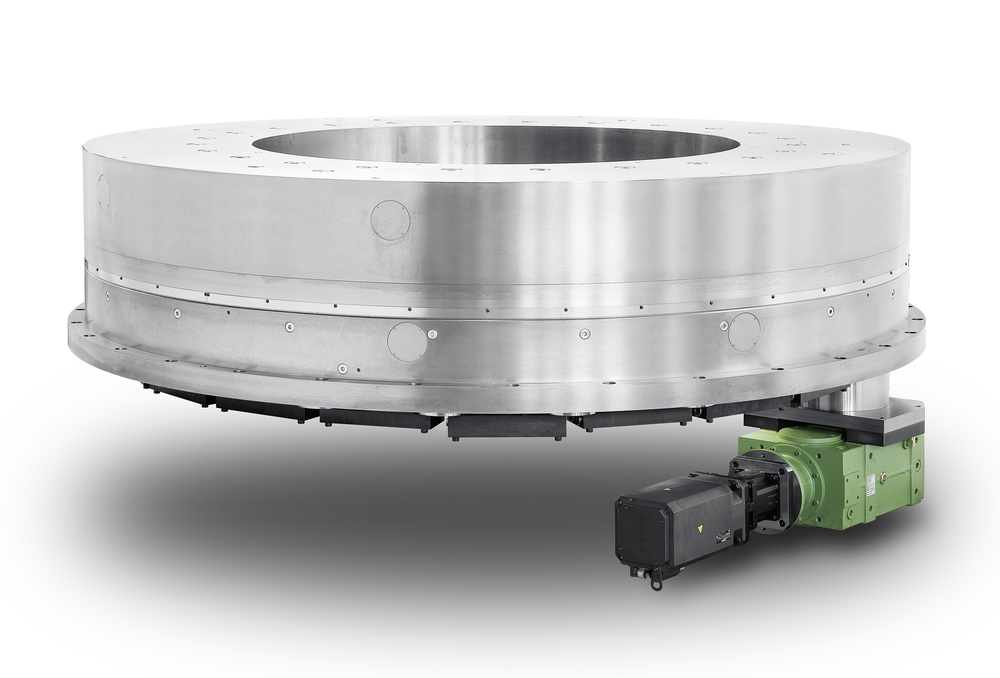

FIBRODYN® DA

Highly dynamic NC rotary tables with direct torque drive

The directly driven FIBRODYN NC rotary tables are designed for highly dynamic and high-precision turning and positioning tasks in machine tools and production systems. With extremely short switching times, they enable flexible positioning in freely selectable angular steps. FIBRODYN works completely without gear parts, which ensures zero backlash and thus high control quality. With the high-precision rotary tables, both very high and very low, uniform indexing table speeds are possible with a repeat accuracy of less than 0.2 angular seconds. The axial and radial runout accuracy of FIBRODYN is in the μ range. A hydraulic table top clamp connects the table top with the housing in a non-positive manner without any drive components protruding beyond the housing contour. This ensures particularly compact dimensions.

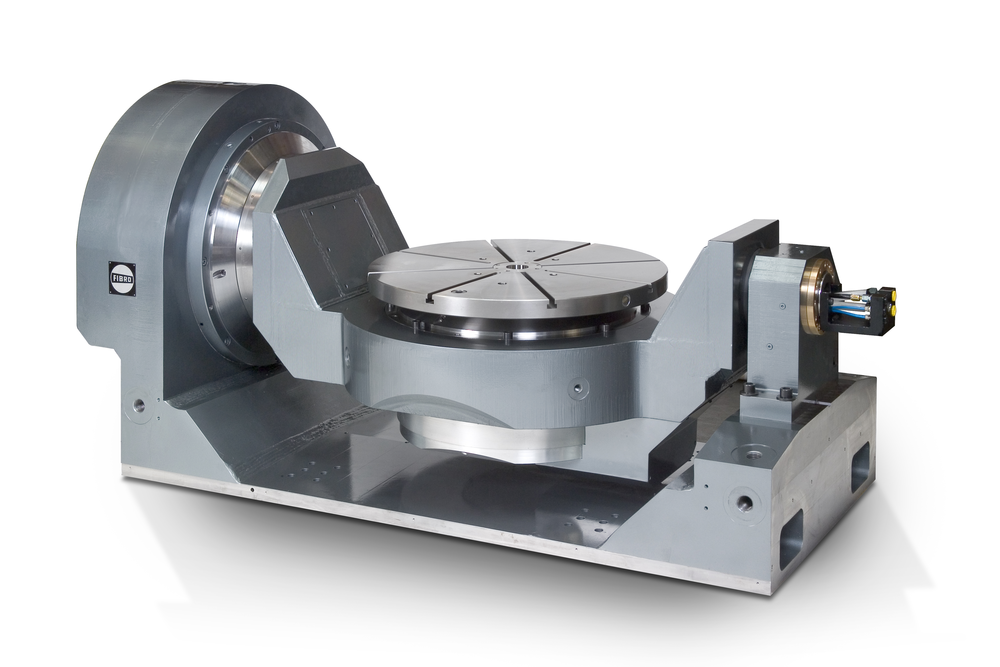

FIBROTAKT® STANDARD WITH FACE GEAR

FIBROTAKT® indexing tables have been developed for precision divisions and the absorption of high machining forces. Interlocking in the FIBRO face gear ensures continuous high precision and rigidity. Different versions and drive types ensure optimum device selection for the respective application. Even for heavy structures, the flush-mount rotary table FIBROTAKT® for rotary transfer machines combines minimum switching times with maximum precision and rigidity. It features a non-lifting indexing table, girth gear drive and easy access from below.