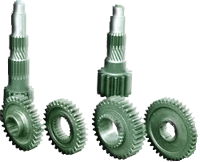

Helical Gear

Helical gear is a cylindrical shaped gear with helicoid teeth. Helical gears operate with less noise and vibration than spur gears. At any time, the load on helical gears is distributed over several teeth, resulting in reduced wear. Due to their angular cut, teeth meshing results in thrust loads along the gear shaft. This action requires thrust bearings to absorb the thrust load and maintain gear alignment. They are widely used in industry. A negative is the axial thrust force the helix form causes.

Helical gears are a type of industrial gears. These gears have angled teeth that creates a thrust load on the gears while they are meshing. They are circular in shape. The teeth of helical gears are curved along a helical path. There is a refinement in design, which helical gears enjoy over Spur Gears. Actually the leading edges of the teeth in helical gears are designed in such a way as not to be parallel to the axis of rotation. Instead, these gears are set angularly. As the gear shape is curved, the unique angle makes the tooth shape to be like a segment of helix. The angled helical gear teeth is able to engage more gradually than the spur gear teeth and makes it run in more smoothly and quietly as well.HELICAL GEARS when used on parallel shafts are similar in usage to spur gears. Where velocities exceed 1000 feet per minute, helical gears provide a stronger, smoother running gear train.

This type of stock gearing is furnished in 45° helix angle. Materials available are hardened steel, steel, stainless, aluminum, bronze, nylon and non-metallic (phenolic). End Thrust is developed by helical gears, but this may be overcome through the use of thrust washers or other suitable types of thrust bearings.

The teeth on helical gears are cut at an angle to the face of the gear. When two teeth on a helical gear system engage, the contact starts at one end of the tooth and gradually spreads as the gears rotate. Two mating helical gears must have equal helix angle but opposite hand. They run smoother and more quietly. They have higher load capacity, are more expensive to manufacture. Helical gears can be used to mesh two shafts that are not parallel and can also be used in a crossed gear mesh connecting two perpendicular shafts. They have longer and strong teeth. They can carry heavy load because of the greater surface contact with the teeth. The efficiency is also reduced because of longer surface contact. The gearing is quieter with less vibration.

One interesting thing about helical gears is that if the angles of the gear teeth are correct, they can be mounted on perpendicular shafts, adjusting the rotation angle by 90 degrees.

|

|

Our Products

Spur Gears Spur Gears

Helical Gear Helical Gear

Sprocket Sprocket

Worm and worm wheel Worm and worm wheel

Racks and Pinion Racks and Pinion

Bevel Gears Bevel Gears

Timing Belt Pulley Timing Belt Pulley

|